|

|

|

| Client Case

Studies: 1-100 I Before

& After Photo Gallery I Client Testimonials I Contact York Property Co |

|

| >>1-10 >>11-20 >>21-30 >>31-40 >>41-50 >>51-60 >>61-70 >>71-80 >>81-90 >>91-100 |

|

|

York Property Company provides proven metal building facade cleaning, refinishing

and restoration solutions for hard water stained anodized

aluminum wall panels, corroded painted aluminum curtain wall

mullions and degraded stainless steel building

facade window frame finishes. At York Property Company we emphasize the distinction between what can be done and what needs to be done.

Attention to detail is the hallmark of the York Property Company experience.

|

|

|

|

Have a Question? Ask Us: Contact the metal building facade and metal curtain wall cleaning, refinishing and restoration professionals today at 610.442.2131 for nationwide service in the United States and Canada.

The York Property Company technical staff

has decades of experience in damaged metal building facade problem identification and causes with

the field experience, knowledge and expertise to provide the correct and most

appropriate metal cleaning, refinishing and restoration specification to suit the needs of the subject property; we plan, specify and enable solutions.

Our quality control standards, thoroughly trained field crews and constant field supervision ensure our Class A client building owners and managers optimum results with each York Property Company project. |

|

|

|

|

|

| Case Study 61 - Chattanooga, Tennessee - Dirty Stainless Steel Building Facade Restoration |

|

|

|

>> View Case Study here.

|

|

Condition:

This hospital in Chattanooga, Tennessee was built thirty years ago. After

years of exposure the exterior stainless steel building facade panels

were dirty, stained, degraded and contaminated from corrosive and

damaging waterborne and airborne contaminants. Compounding the problem was leaching

plasticizers and silicone from the degraded caulking. There had been no

remedial maintenance washing over the life of the building which

contributed to the severity of the contamination. The hospital is a

Class A facility and the unsightly condition of the building facade had

to be remedied. Due to our renowned stainless steel restoration

expertise, our client contracted us to remove the contaminants and

caulking residue returning the stainless steel panels to their original

condition. This stainless steel cleaning program will leave the stainless steel building facade

clean and contaminant free for many years to

come.

York Property Company

Solution:

Cleaning and repairing the damaged and dirty stainless

steel panels required our years of oxidized stainless steel refinishing

and

caulking stained stainless steel restoration experience. As stainless

steel building facade cleaning and stainless steel restoration

specialists we restoration cleaned

the stainless steel building facade cladding panels with our dirty

stainless

steel restoration cleaning and caulking stained refinishing systems.

This program made

the dirty, oxidized and stained building facade panels shine. The

staining, corrosion and silicone caulking residue was expertly removed

as to

not further damage the satin stainless steel finish on the stainless

steel building facade panels. |

|

|

|

|

|

| Case Study 62 - Ft. Myers, Florida - Repairing Stained Anodized Aluminum Windows |

|  |

|

|

>> View Case Study here.

|

|

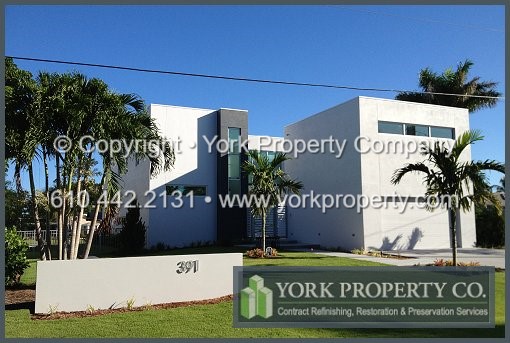

Condition:

The new clear anodized aluminum factory finish was stained and etched

during the construction of this Ft. Myers, Florida custom home. During construction acidic concrete slurry, mortar and

corrosive cement splashed on the anodized aluminum window frames and

anodized aluminum doors. The silver colored anodized finish was acid

etched, corroded, scratched and oxidized. The G.C. requested that we

get the concrete, cement and mortar overspray stains off and get the

acid etching out of the anodized aluminum surfaces. As acid burned

anodized aluminum cleaning and chemically etched anodized aluminum

refinishing experts, our client had confidence we could recondition,

refinish and restore the damaged anodized aluminum surface finishes.

York Property Company Solution:

To clean, repair, renew and protect the damaged anodized aluminum

surfaces we refurbished the anodized aluminum with our acid etched

anodized aluminum restoration cleaning and oxidized anodized aluminum

reconditioning system. We had to remove the concrete, cement and mortar

overspray, splatter and debris while repairing and refinishing the

anodized aluminum without causing any more damage to the thin anodized

anodic finish. Although the anodized aluminum building facade window

mullions and doors were seriously damaged, our anodized aluminum

construction cleaning, restoration and rejuvenating program allowed us

to clean, repair, refurbish and restore the acid etched and oxidized

anodized aluminum to "like new". The anodized aluminum is protected

from further corrosion, oxidation and pitting. |

|

|

|

|

|

Case Study 63 - Clearwater, Florida - Stripping Paint on Anodized Aluminum Window Frames

|

|

|

|

>> View Case Study here.

|

|

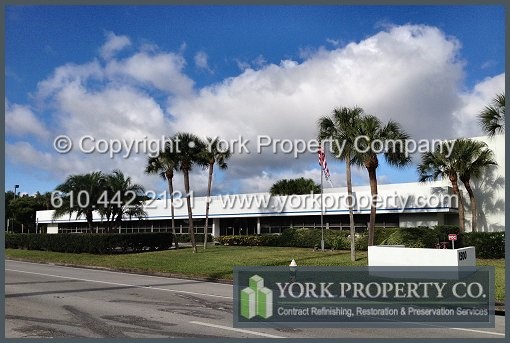

Condition:

The commercial bronze anodized aluminum window frames on this industrial

building in Clearwater, Florida were painted after they were installed on

the building. Over time the brown paint coating on the anodized aluminum window

frames got chalky and the pigment faded. The old weathered paint had to be

removed. The new owner of the building wanted the anodized aluminum window frames to be

restored to the original luster of new brown colored anodized aluminum. If the anodized aluminum was not

coated once it was clean and refurbished the anodized aluminum and

anodic layer would bleach, stain, acid etch and oxidize. To maintain

the integrity of the brown colored bronze anodic finish ownership

requested the anodized aluminum storefront window frames be coated

and protected with the York Property Company anodized aluminum clear

protective coating.

York Property Company

Solution: To refurbish and recondition the weathered and faded anodized aluminum window frames we had to chemically strip the paint

off the anodized aluminum finish without damaging the brown anodic

layer. Removing the paint was time consuming and required our skill,

expertise and experience as commercial anodized aluminum window frame

restoration contracting specialists. If the window frames were

bleached, burned, acid etched or scratched the anodized

aluminum would have to be painted again. The anodized aluminum

reconditioning program got the paint off of the anodized aluminum

window frames safely and refurbished the anodized aluminum dark brown

color and finish. The anodized aluminum protective coating enhanced the

reflective sheen and gloss while protecting the anodized aluminum from

the sun, mineral deposits, calcium stains and caustic airborne

contaminants. |

|

|

|

|

|

Case Study 64 - Alachua, Florida - Removing Stucco on Anodized Aluminum Windows

|

|

|

|

>> View Case Study here.

|

|

Condition:

This new commercial building in Alachua, Florida had acid and

chemical burned anodized aluminum storefront window frames and stucco

contaminated anodized aluminum capped curtain wall window mullions. The

clear anodized aluminum extruded finishes were damaged, oxidized, acid

etched and stained by stucco overspray during the stucco application.

The anodized aluminum whitish beige stucco residue, construction

debris, oxidation damage, discoloration and staining had to be removed

from the anodized aluminum window frames.

York Property Company Solution:

The architect specified our firm as construction damaged anodized

aluminum cleaning and refinishing experts. The General Contractor

contracted us to use our anodized aluminum stucco removal expertise to

remove the stucco overspray, residue, particles and debris from the

stained anodized aluminum window frames and mullions. We field applied

our anodized aluminum stucco removal and construction cleaning program

to restore the new building facade anodized aluminum window frame

sections. Upon completion, the anodized aluminum looked new, clean and

free of any oxidation, acid etching or stucco damage. |

|

|

|

|

|

Case Study 65 - Manhattan, New York - Anodized Aluminum Curtain Wall Restoration

|

|

|

|

>> View Case Study here.

|

|

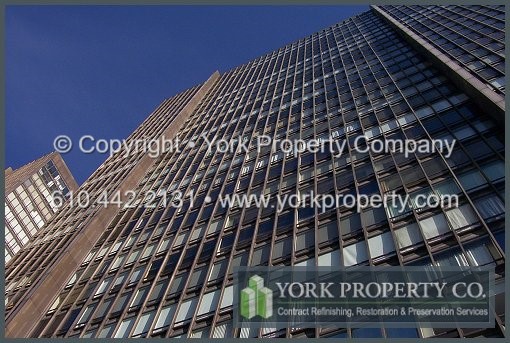

Condition:

This luxury residential condominium in Manhattan, New York had dull

bronze anodized aluminum curtain wall panels, faded anodized aluminum

window mullions and bleached anodized aluminum extrusions. The exterior

anodized aluminum facade had not been washed or cleaned in over twenty

years. Management and the owners required short and long-term

maintenance specifications to clean and refurbish the bronze anodized

aluminum clad panels and the anodized aluminum window mullions.

York Property Company Solution:

As oxidized anodized aluminum curtain wall restoration specialists we

were retained to analyze the anodized aluminum components, conduct

tests and prepare remedial anodized aluminum cleaning and anodized

aluminum maintenance specification documents. With the findings of our

analysis and our anodized aluminum remedial maintenance restoration

specification a dirty anodized aluminum cleaning, washing, refinishing

and maintenance program was implemented. When this anodized aluminum

refinishing and refurbishing program was complete the bronze anodized

aluminum was corrosion free, clean and protected from further damage. |

|

|

|

|

|

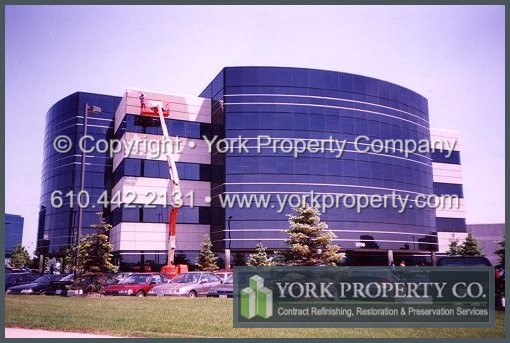

| Case Study 66 - Toronto, Ontario - Restoring Faded Painted Aluminum Window Mullions |

|

|

|

>> View Case Study here.

|

|

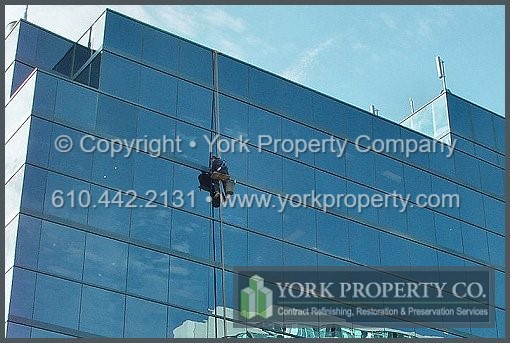

Condition:

The blue painted aluminum curtain wall window mullions, painted

aluminum window frames and painted aluminum panels on this commercial

building in Toronto, Ontario had degraded and weathered from thirty

years of sun and UV exposure, airborne pollutants, contaminants and

the lack of painted aluminum preventive maintenance washing. The

painted aluminum curtain wall mullions, painted aluminum window frames

and painted aluminum panels were chalked, faded, damaged, oxidized,

pitting and stained from vertical silicone leaching, caulking bleeding

and sealant runoff streaking. The original paint finish looked

aged and old after losing the factory gloss, paint color, luster and

sheen. All of the damaging caustic elements had to be removed prior to painting.

York Property

Company Solution:

The eleven storey painted aluminum curtain wall extrusions were not clean,

damaged, stained, streaked and were visually displeasing. The original

factory applied faded paint finishes required oxidation, bleeding

caulking and leaching sealant removal. We painted the damaged and oxidized painted aluminum window frames,

painted aluminum mullions and painted aluminum panels with our spray applied Kynar ADS Fluoropolymer refinishing system. The

exterior of the Warner Brothers building looks renewed, clean and

rejuvenated. The building now has the original factory paint gloss, sheen and color.

|

|

|

|

|

|

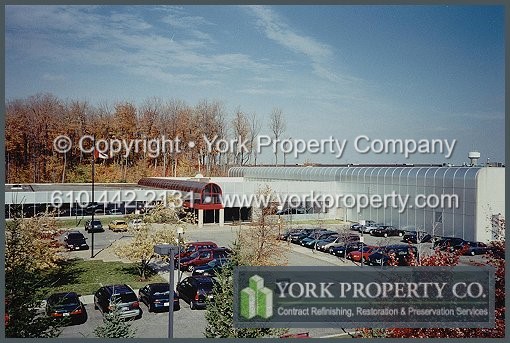

Case Study 67 - Mississauga, Ontario - Anodized Aluminum and Concrete Restoration

|

|

|

|

>> View Case Study here.

|

|

Condition:

The precast concrete panels and the black building facade anodized

aluminum window mullions on this commercial building in Mississauga, Ontario were degraded and stained from years of

exposure to pollutants and contaminants. The precast concrete was

stained and there were streaks from dirty water running down the

building from the horizontal anodized aluminum mullions. There was mold

and mildew growing on the concrete on the side of the building that was

usually in the shade. The exterior anodized aluminum and concrete

surfaces of the building were visibly dirty, stained and required

restoration cleaning and chemical washing. The owners of the building

required we improve the appearance and bring new life to the exterior

of their Class A commercial building.

York Property Company

Solution:

As anodized aluminum metal refinishing contractors and precast concrete

restoration cleaning specialists we were contracted to wash, restore

and renovate the four storey building facade anodized aluminum window

frames and precast concrete panels. Our biodegradable chemical cleaning

program removed years of accumulated dirt, corrosion, stains,

oxidation, window cleaning runoff, mold and mildew contamination. When

completed the exterior concrete was back to the original color and the

black anodized aluminum was clean, restored, repaired, refinished and

protected from dirt, corrosion and staining. |

|

|

|

|

|

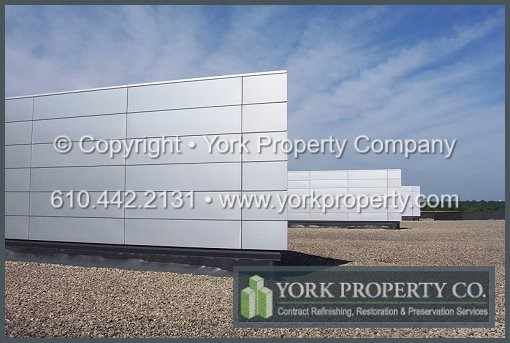

| Case Study 68 - Madison, Wisconsin - Stained Anodized Aluminum Facade Refinishing |

|

|

|

>> View Case Study here.

|

|

Condition:

The clear anodized aluminum clad siding panels on this commercial building in Madison, Wisconsin displayed severe

discoloration, oxidation, staining and corrosion from years of

weathering and a lack of preventive washing or maintenance. The factory

anodized finish lost the original sheen, gloss, color depth and luster.

Management decided to refurbish, renew and rejuvenate the original

factory anodized aluminum finish to avoid chipping, peeling and flaking

paint. Refurbishing the anodized finish will protect and preserve the

exterior anodized aluminum siding panels from weathering, pollutants,

contaminants, hard water stains, mold, mildew and the damaging elements.

York Property Company Solution:

To clean, repair, renew and protect the anodized aluminum siding from

further oxidation, corrosion, pitting and deterioration we cleaned and

refurbished the original anodized finish with our anodized aluminum

cleaning and renovation system. Without painting, our oxidized anodized

aluminum refinishing and refurbishing program returned the anodized

aluminum factory finish to as good as new and now protects the anodized

finish from weathering, pitting, oxidation and corrosion. The anodized

finish has the original sheen, color depth and gloss protected from

further damage. |

|

|

|

|

|

Case Study 69 - Markham, Ontario - Restoring Oxidized Anodized Aluminum Panels

|

|

|

|

>> View Case Study here.

|

|

Condition:

The clear anodized aluminum building facade panels, anodized aluminum

mullions, anodized aluminum storefront window frames and anodized metal

extrusions on this commercial building in Markham, Ontario were dirty, oxidized and

stained. The anodized silver color and satin sheen had faded. The

anodized aluminum cladding panels were contaminated with mold, mildew,

mineral and calcium deposits. Apple Computer Inc. wanted a mold and

mildew stain removal program to repair, restore and refinish the

anodized metal surface staining and damage to the anodized aluminum

building facade panels.

York Property

Company

Solution: The dull, bleached and damaged exterior anodized

aluminum panels and anodized aluminum window frames on this building

were cleaned, repaired and restored with our exterior anodized aluminum

refinishing system. The anodized aluminum was restoration cleaned

removing the oxidation, mold and mildew stains, and the calcium and

mineral deposits. The anodized aluminum metal cladding and anodized

aluminum metal storefront window frames were coated with our spray

applied clear lacquer protective coating to protect the anodized

aluminum metal finish from further damage, corrosion and weathering.

|

|

|

|

|

|

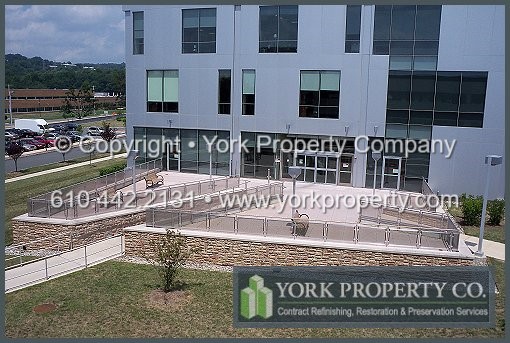

| Case Study 70 - Morris Plains, New Jersey - Removing Rust from Stainless Steel Railings |

|

|

|

>> View Case Study here.

|

|

Condition:

The architectural stainless steel railings at Johnson and Johnson in

Morris Plains, New Jersey were rusting, oxidized, weathered and

pitting. Corrosion, staining and tarnish had overtaken the stainless

steel railing finishes. A lack of stainless steel maintenance washing

allowed the stainless steel finish to wear out, get old, get salt

damaged, corrode, oxidize and rust. The original stainless steel gloss

and sheen had worn off and the stainless steel had an iron oxide brown

patina. The stainless steel needed to be renewed, polished, resurfaced

and refinished to make the stainless steel railings shine and have the

original factory stainless steel satin finish and luster.

York Property Company Solution:

We removed the stainless steel rust, repaired the stainless steel

damage and restored the stainless steel railing finishes over a weekend

when the building was closed. To complete the stainless steel

refinishing and stainless steel restoration project we had to get the

rust off the stainless steel and remove the corrosion, patina,

scratches and stains. The stainless steel surface rust, corrosion,

pitting and discoloration required our stainless steel rust removal and

stainless steel metal refinishing systems to achieve the desired satin

stainless steel surface finish and color depth. As stainless steel

cleaning, stainless steel refinishing and stainless steel maintenance

experts the stainless steel railings are now clean, rejuvenated,

restored and protected. |

|

|

|

|

|

|

|

York

Property Company

provides professional rusting stainless steel curtain wall panel

cleaning,

faded painted aluminum building facade siding refinishing, dirty

anodized

aluminum storefront window frame cleaning and discolored stainless

steel building facade refinishing solutions that restore the color,

gloss, luster, sheen and visual appearance.

Our highly trained company

technicians clean, repair, refinish and restore anodized aluminum,

painted aluminum and stainless steel finishes on-site.

Ask an Expert: Contact the metal building facade cleaning and refinishing experts today at 610.442.2131

and

request a comprehensive analysis of your building's dirty, faded, sun

damaged and

oxidized exterior metal finishes.

Schedule a Site Visit: Our industry-leading,

skilled, experienced and knowledgeable technical consultants will

specify a customized long-lasting and cost-effective

weathered stainless steel building facade panel cleaning, stained

painted aluminum curtain wall panel washing and oxidized anodized

aluminum

curtain wall panel refinishing specification that will beautify,

improve, recondition, restore and protect all your architectural metal

finishes. |

|

|

|

|

|

|

| United States:

Alabama, Alaska, Arizona, Arkansas, California, Colorado, Connecticut,

Delaware, Florida, Georgia, Hawaii, Idaho, Illinois, Indiana, Iowa,

Kansas, Kentucky, Louisiana, Maine, Maryland, Massachusetts, Michigan,

Minnesota, Mississippi, Missouri, Montana, Nebraska, Nevada, New

Hampshire, New Jersey, New Mexico, New York, North Carolina, North

Dakota, Ohio, Oklahoma, Oregon, Pennsylvania, Rhode Island, South

Carolina, South Dakota, Tennessee, Texas, Utah, Vermont, Virginia,

Washington, West Virginia, Wisconsin and Wyoming. |

|

| Canada: Alberta, British Columbia, Manitoba, Ontario, Quebec and Saskatchewan. |

|

|

|

|

|