|

|

|

| Client Case

Studies: 1-100 I Before

& After Photo Gallery I Client Testimonials I Contact York Property Co |

|

| >>1-10 >>11-20 >>21-30 >>31-40 >>41-50 >>51-60 >>61-70 >>71-80 >>81-90 >>91-100 |

|

|

York Property Company

provides proven metal building facade cleaning, refinishing

and restoration solutions for degraded stainless steel curtain wall

window mullions, uneven anodized aluminum storefront window frames and

discolored painted aluminum

building facade finishes. At York Property Company we emphasize the distinction between what can be done and what needs to be done.

Attention to detail is the hallmark of the York Property Company experience.

|

|

|

|

Have a Question? Ask Us: Contact the metal building facade and metal curtain wall cleaning, refinishing and restoration professionals today at 610.442.2131 for nationwide service in the United States and Canada.

The York Property Company

technical staff

has decades of experience in damaged metal building facade problem

identification and causes with

the field experience, knowledge and expertise to provide the correct

and most

appropriate metal cleaning, refinishing and restoration specification

to suit the needs of the subject property; we plan, specify and enable

solutions.

Our quality control standards, thoroughly trained field crews and

constant field supervision ensure our Class A client building owners

and managers optimum results with each York Property Company project. |

|

|

|

|

|

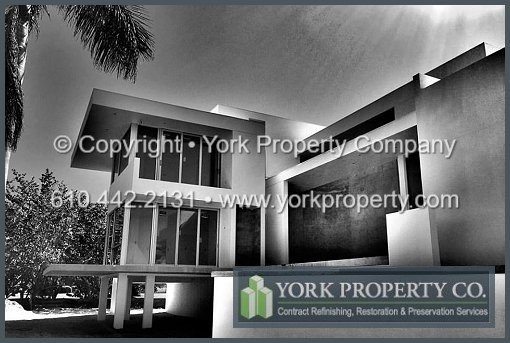

Case Study 91 - Longboat Key, Florida - Repairing Acid Etched Anodized Aluminum Windows

|

|

|

|

|

|

>> View Case Study here.

|

|

Condition:

The new clear anodized aluminum factory finish was stained and etched

during the construction of this Longboat Key, Florida custom home. During construction acidic concrete slurry, mortar and

corrosive cement splashed on the anodized aluminum window frames and

anodized aluminum doors. The silver colored anodized finish was acid

etched, corroded, scratched and oxidized. The G.C. requested that we

get the concrete, cement and mortar overspray stains off and get the

acid etching out of the anodized aluminum surfaces. As acid burned

anodized aluminum cleaning and chemically etched anodized aluminum

refinishing experts, our client had confidence we could recondition,

refinish and restore the damaged anodized aluminum surface finishes.

York Property Company Solution:

To clean, repair, renew and protect the damaged anodized aluminum

surfaces we refurbished the anodized aluminum with our acid etched

anodized aluminum restoration cleaning and oxidized anodized aluminum

reconditioning system. We had to remove the concrete, cement and mortar

overspray, splatter and debris while repairing and refinishing the

anodized aluminum without causing any more damage to the thin anodized

anodic finish. Although the anodized aluminum building facade window

mullions and doors were seriously damaged, our anodized aluminum

construction cleaning, restoration and rejuvenating program allowed us

to clean, repair, refurbish and restore the acid etched and oxidized

anodized aluminum to "like new". The anodized aluminum is protected

from further corrosion, oxidation and pitting. |

|

|

|

|

|

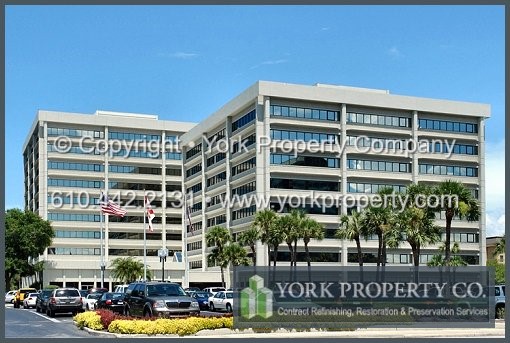

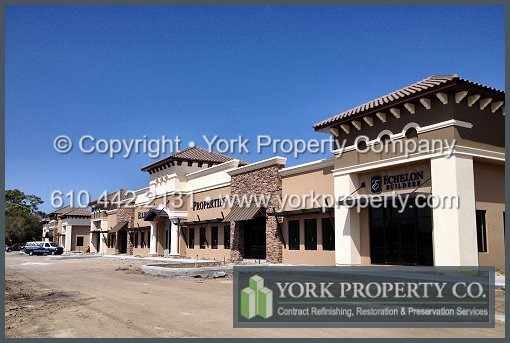

Case Study 92 - Tampa, Florida - Removing Peeling Paint on Anodized Aluminum

|

|

|

|

>> View Case Study here.

|

|

Condition: The Kawneer Class I

exterior bronze anodized aluminum window frames on these commercial

buildings in Tampa, Florida were painted after they were installed on

the building. The brown paint coating on the anodized aluminum window

frames were peeling and the old, brittle, flaking paint had to be

removed. The owners wanted the anodized aluminum window frames to be

restored to the original luster of new brown colored anodized aluminum

window frames, sills and flashing. If the anodized aluminum was not

coated once it was clean and refurbished the anodized aluminum and

anodic layer would bleach, stain, acid etch and oxidize. To maintain

the integrity of the brown colored bronze anodic finish ownership

requested the anodized aluminum building facade window frames be coated

and protected with the York Property Company anodized aluminum clear

protective coating.

York Property Company Solution:

To refurbish and recondition the old, faded and contaminated exterior

anodized aluminum window frames we had to chemically strip the paint

off the anodized aluminum finish without damaging the brown anodic

layer. Removing the paint was time consuming and required our skill,

expertise and experience as commercial anodized aluminum window frame

restoration contracting specialists. If the window frames were

bleached, burned, oxidized, acid etched or scratched the anodized

aluminum would have to be painted again. The anodized aluminum

reconditioning program got the paint off of the anodized aluminum

window frames safely and refurbished the anodized aluminum dark brown

color and finish. The anodized aluminum protective coating enhanced the

reflective sheen and gloss while protecting the anodized aluminum from

the sun, mineral deposits, calcium stains and caustic airborne

contaminants. |

|

|

|

|

|

Case Study 93 - New Orleans, Louisiana - Hurricane Damaged Anodized Aluminum Restoration

|

|

|

|

>> View Case Study here.

|

|

Condition:

During Hurricane Katrina the black anodized aluminum metal finishes on

this commercial building in New Orleans, Louisiana were scratched,

dented and damaged by wind driven airborne particulate and debris. The

black anodized aluminum doors, anodized aluminum storefront and

anodized aluminum window frames were scratched, marred, scuffed, dull

and faded as the wind driven debris abraded the surface of the anodized

aluminum metal finishes.

York Property Company Solution:

Working with Zurich Insurance we were able to ascertain what anodized

aluminum metal damage was hurricane related and what was general

weathering - anodized aluminum color fading, anodized aluminum finish

oxidation, anodized aluminum surface corrosion, anodized aluminum

pitting and anodized aluminum staining. With our oxidized anodized

aluminum refinishing and scratched anodized aluminum metal restoration

expertise our metal surface analysis and metal repair specification

allowed Zurich Insurance to settle with the buildings owner to clean,

refinish and restore the specified anodized aluminum surfaces. |

|

|

|

|

|

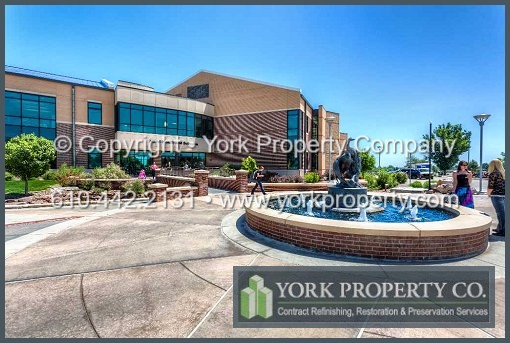

Case Study 94 - Greeley, Colorado - Oxidized Anodized Aluminum Construction Cleaning

|

|

|

|

>> View Case Study here.

|

|

Condition:

The dark bronze anodized aluminum storefront window mullions, anodized

aluminum doors and anodized aluminum metal window frames on this

Greeley, Colorado commercial building were damaged, acid etched,

corroded, oxidized and stained during the mortar acid cleaning process.

The anodized aluminum new construction project was compromised by the

concrete, cement and mortar etching, corrosion, damage and stains.

York Property Company Solution:

The G.C. required that we repair the anodized aluminum damage and

remove the anodized aluminum staining, etching, corrosion and

oxidation. We cleaned, repaired and restored the new anodized aluminum

curtain wall window mullions, anodized aluminum doors and anodized

aluminum window frames as if they had not been damaged by the concrete

and mortar overspray. The building facade anodized aluminum silver

color, metallic satin sheen and gloss looked new and clean when the

mortar and concrete contamination removal construction cleaning process

was complete. |

|

|

|

|

|

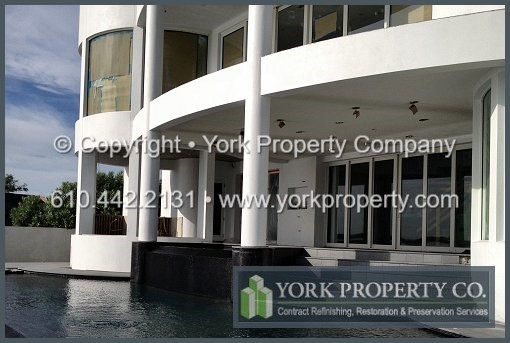

Case Study 95 - Lafayette, Louisiana - Restoring Acid Etched Anodized Aluminum Windows

|

|

|

|

>> View Case Study here.

|

|

Condition: The new clear anodized aluminum window frames and the 10' high anodized aluminum

lanai door frames on this custom home in Lafayette, Louisiana

were damaged, stained, oxidized and acid etched by the brick mason contractor acid

cleaning the brick above the anodized aluminum window frame

extrusions. The muriatic acid restoration cleaning agent flash etched and

burned all of the building facade clear anodized aluminum. The milky

white chemical staining left the silver metallic anodized aluminum

damaged, flash oxidized and acid burned beyond repair by traditional construction cleaning methods and materials.

York Property Company Solution:

The General Contractor retained us as acid etched anodized aluminum

construction cleaning contracting experts. We were contracted to clean,

repair and restore the chemical stained and muriatic acid burned

anodized aluminum storefront window frames and anodized aluminum lanai

door frames. This project required that we repair the acid etching

damage and return the anodized aluminum to the original condition

without painting, capping or replacing any of the anodized aluminum

extrusions. The two storey acid

etched anodized aluminum residential building facade storefront was

repaired and restored to the original color and sheen specification

with our acid etched anodized aluminum construction cleaning and

restoration system.

|

|

|

|

|

|

Case Study 96 - Clearwater Beach, Florida - Field Painting Aluminum Windows

|

|

|

|

>> View Case Study here.

|

|

Condition:

The factory applied white paint finish on the new exterior painted

aluminum window frames had started cracking and peeling due to interior

paint being applied at the factory vs. exterior paint as specified. The

paint finish was prematurely fading, flaking off and peeling. The G.C.

required that this situation be remedied immediately as the luxury

ocean front residence in Clearwater Beach, Florida was still under

construction.

York Property Company Solution:

As painted aluminum window frame restoration contracting specialists we

were contracted to mobilize on-site and chemically strip the failing

paint and abrade the window frames down to the mill finish aluminum. We

could not paint over the failing paint as the bond line adhesion was

compromised. After the stripping and surface cleaning was complete we

primed and then spray applied the originally specified paint to all

exterior painted aluminum window frame surfaces. |

|

|

|

|

|

Case Study 97 - Rockledge, Florida - Repairing Stucco Stains on Anodized Aluminum

|

|

|

|

>> View Case Study here.

|

|

Condition:

The new Class I bronze anodized aluminum storefront window frames and

anodized aluminum doors on this large construction project in

Rockledge, Florida were oxidized and acid etched during construction.

The factory finished anodized aluminum surface finish was acid burned,

blemished and stained whitish gray with lime contaminated debris,

acidic water and stucco overspray. The stucco contractor failed to tape

the window frame perimeter edge correctly allowing acidic stucco to

leech onto the fragile bronze anodic layer. The anodized aluminum new

construction project was compromised by the stucco and lime residue,

white stucco splatter, scarring and acid burns.

York Property Company Solution:

The General Contractor contracted us to clean,

repair and restore the damaged, oxidized and acid etched bronze

anodized aluminum

window frames. We removed the acid burns and white colored stains on

the

new anodized aluminum window frame sections as if they had not been

acid etched, stained or damaged. The architect specified that we repair

the acid etching damage and return the anodized aluminum to the

original condition. The bronze anodized aluminum looked new and clean

when the anodized aluminum construction cleaning and anodized aluminum

stucco and acid etching removal program was complete. |

|

|

|

|

|

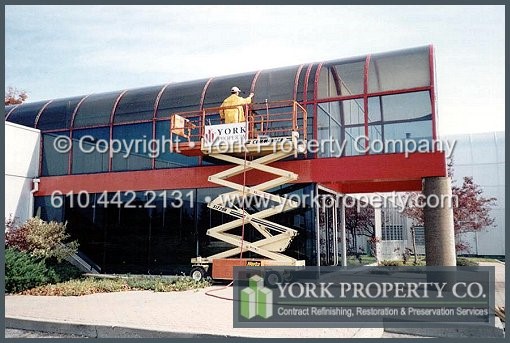

| Case Study 98 - Markham, Ontario - Faded Painted Aluminum Entrance Canopy Refinishing |

|

|

|

>> View Case Study here. |

|

Condition:

The original red factory paint coating on the painted aluminum entrance

canopy panels and painted aluminum mullions at this commercial building

in Markham, Ontario lost the original sheen, gloss, color depth and luster. The painted

aluminum panels and painted aluminum window frames were oxidized,

faded, chalked and bleached. To avoid chipping, peeling and flaking

paint our client chose to refurbish, renew and rejuvenate the original

factory applied paint finish. Painted aluminum oxidation removal and

reconditioning the paint finish will protect and preserve the painted

aluminum from weathering and pollutants.

York Property Company Solution:

To clean, repair, renew and protect the paint finish from further

oxidation, corrosion, pitting and deterioration, we refurbished and

reconditioned the painted aluminum canopy surfaces original paint

finish with our painted aluminum cleaning and restoration system. Our

faded paint refinishing and refurbishing program returned the painted

aluminum factory finish to as good as new and now protects the paint

finish from weathering and oxidation. The paint finish has the original

sheen, color depth and gloss protected from U.V. exposure and corrosion. |

|

|

|

|

|

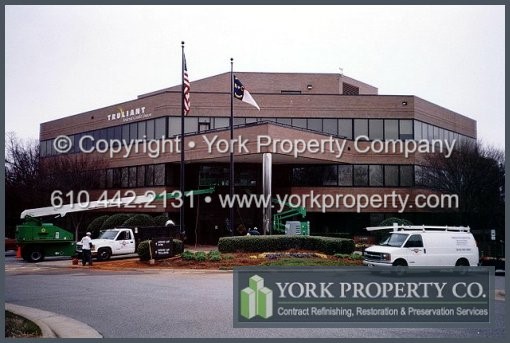

Case Study 99 - Winston-Salem, North Carolina - Stained Anodized Aluminum Refinishing

|

|

|

|

>> View Case Study here.

|

|

Condition:

The service life of the exterior bronze anodized aluminum on this

commercial building in Winston-Salem, North Carolina had expired. The

bronze anodized aluminum building facade storefront window frames and

doors on this owner occupied Winston-Salem Credit Union had degraded

from age, environmental contaminants, pollutants, acid rain and a lack

of anodized aluminum preventive maintenance washing. The anodized

aluminum metal was damaged, faded, oxidized, pitting and stained.

Ownership required the stains, oxidation and damage to the anodized

aluminum be cleaned, repaired and refurbished to return the bronze

anodized aluminum window frames to a preserved and protected condition.

York Property Company Solution:

To repair, restore and protect the brown colored anodized aluminum

building facade window frames and doors from the damaging elements

anodized aluminum restoration cleaning was specified with an

application of our anodized aluminum clear protective coating. Without

painting, our oxidized anodized aluminum cleaning and refinishing

program returned the bronze anodized aluminum window frames factory

finish to as good as new and now protects the anodic finish from

weathering, pitting, oxidation and corrosion. The specified anodized

aluminum remedial maintenance process cleans, repairs, protects and

preserves anodized aluminum surfaces from damaging pollutants and

contaminants. |

|

|

|

|

|

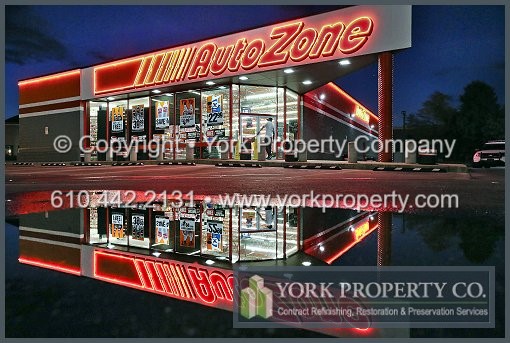

Case Study 100 - Memphis, Tennessee - Painted Aluminum Storefront Remedial Maintenance

|

|

|

|

>> View Case Study here.

|

|

Condition:

The red painted aluminum storefront window frames at over 4000 AutoZone

retail locations nationwide were getting dirty, faded, discolored and

contaminated. There was no short or long-term maintenance washing

program in place for the painted aluminum storefront window frame extrusions. Most locations

had not been washed or restoration cleaned in over twenty

years. AutoZone Corporate Facility Management in Memphis, Tennessee

required a short & long-term maintenance specification to clean and

refurbish the painted aluminum storefront window frames.

York Property Company

Solution: As weathered painted aluminum window frame restoration

contracting specialists we were retained to analyze the painted

aluminum at locations in Pennyslvania, North Carolina and Texas. With the findings of our tests and analysis we prepared

remedial painted aluminum cleaning and maintenance specification

documents. With our painted aluminum

remedial maintenance washing specification a national painted aluminum

cleaning and washing program was implemented. |

|

|

|

|

|

|

|

York

Property Company

provides professional oxidized anodized aluminum corrugated cladding

restoration, faded anodized aluminum siding panel refinishing and mold

stained anodized aluminum spandrel panel system restoration cleaning

solutions that restore the color, gloss, luster, sheen and visual

appearance.

Our highly trained company

technicians clean, repair, refinish and restore anodized aluminum,

painted aluminum and stainless steel finishes on-site.

Ask an Expert: Contact the metal building facade cleaning and refinishing experts today at 610.442.2131

and request a comprehensive analysis of your building's acid stained,

scarred, corroded

and blemished exterior metal finishes.

Schedule a Site Visit: Our industry-leading,

skilled, experienced and knowledgeable technical consultants will

specify a customized long-lasting and cost-effective

stained anodized aluminum building facade panel cleaning, rusting

stainless steel cladding refinishing and historical anodized aluminum

curtain wall panel refurbishing specification that will beautify,

recondition, improve, restore and protect all your architectural metal

finishes. |

|

|

|

|

|

|

| United States:

Alabama, Alaska, Arizona, Arkansas, California, Colorado, Connecticut,

Delaware, Florida, Georgia, Hawaii, Idaho, Illinois, Indiana, Iowa,

Kansas, Kentucky, Louisiana, Maine, Maryland, Massachusetts, Michigan,

Minnesota, Mississippi, Missouri, Montana, Nebraska, Nevada, New

Hampshire, New Jersey, New Mexico, New York, North Carolina, North

Dakota, Ohio, Oklahoma, Oregon, Pennsylvania, Rhode Island, South

Carolina, South Dakota, Tennessee, Texas, Utah, Vermont, Virginia,

Washington, West Virginia, Wisconsin and Wyoming. |

|

| Canada: Alberta, British Columbia, Manitoba, Ontario, Quebec and Saskatchewan. |

|

|

|

|

|