|

|

|

| Client Case

Studies: 1-100 I Before

& After Photo Gallery I Client Testimonials I Contact York Property Co |

|

| >>1-10 >>11-20 >>21-30 >>31-40 >>41-50 >>51-60 >>61-70 >>71-80 >>81-90 >>91-100 |

|

|

York Property Company provides proven metal building facade cleaning, refinishing

and restoration solutions for oxidized anodized aluminum

storefront window frames, old painted

aluminum curtain wall mullions and rusting stainless steel building facade clad panel finishes. At York Property Company we emphasize the distinction between what can be done and what needs to be done.

Attention to detail is the hallmark of the York Property Company experience.

|

|

|

|

Have a Question? Ask Us: Contact the metal building facade and metal curtain wall cleaning, refinishing and restoration professionals today at 610.442.2131 for nationwide service in the United States and Canada.

The York Property Company technical staff

has decades of experience in damaged metal building facade problem identification and causes with

the field experience, knowledge and expertise to provide the correct and most

appropriate metal cleaning, refinishing and restoration specification to suit the needs of the subject property; we plan, specify and enable solutions.

Our quality control standards, thoroughly trained field crews and constant field supervision ensure our Class A client building owners and managers optimum results with each York Property Company project. |

|

|

|

|

|

Case Study 41 - Exton, Pennsylvania - Restoring Oxidized Painted Aluminum Panels

|

|

|

|

|

>> View Case Study here.

|

|

Condition: The highly reflective

paint on the exterior building facade metal panels at this Exton, Pennsylvania

location of the U.S.P.S. had failed prematurely. The dull, chalked,

faded and oxidized painted aluminum panels were an eyesore and in need

of cleaning and paint restoration. The paint that was applied during

manufacturing of the aluminum panels was for interior use. The paint

bleached and oxidized in the exterior environment not being able to

withstand the UV rays, heat, pollutants and acidic contaminants that

are present outside. We informed our client that the paint finish could

be restored and coated to protect the pigment from the corrosive

elements.

York Property Company Solution:

As faded, bleached, weathered and oxidized paint restoration experts we

were brought in over a weekend to clean, repair and restore the painted

aluminum building facade panels to their original sheen, gloss and

finish. We used our painted aluminum reconditioning system that removed

the top layer of the factory applied paint finish. This painted

aluminum refinishing program stripped the failed paint resin from the

painted aluminum panel surfaces allowing for a smooth substrate to work

from. We sealed the painted aluminum pores and protected the underlying

paint pigment. The panels are now clean and restored making the

building shine. |

|

|

|

|

|

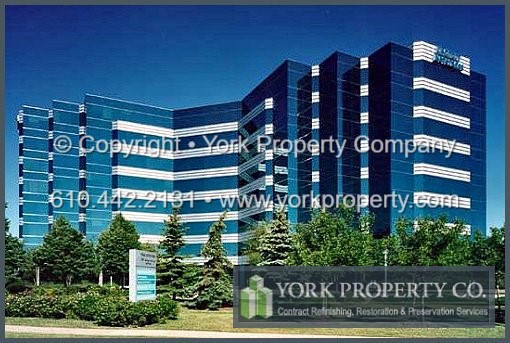

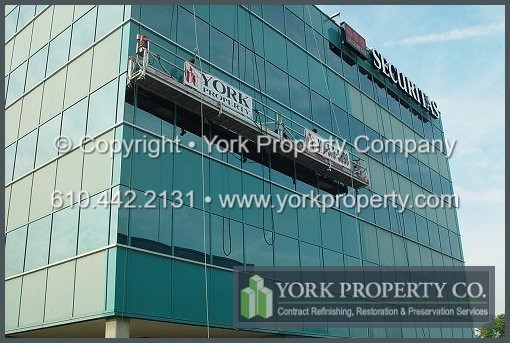

Case Study 42 - Mississauga, Ontario - Refinishing Rusting Stainless Steel Window Mullions

|

|

|

|

>> View Case Study here. |

|

Condition: The architectural metals

on this commercial building in Mississauga, Ontario are horizontal

anodized aluminum panels and stainless steel mullions. The anodized

aluminum was stained and severely oxidized. The stainless steel was

corroding, discolored and starting to rust as it had not been

maintained since the building was new. The anodized aluminum and

stainless steel weathering, oxidation and corrosion was caused by years

of exposure to waterborne pollutants, airborne contaminants, window

cleaning chemicals and UV exposure. Cleaning, refurbishing and

restoring the old, dirty and aged anodized aluminum and stainless steel

was required.

York Property Company Solution: This building is the head office

of a commercial real estate development company and the condition of

the curtain wall anodized aluminum and stainless steel was

unacceptable. The oxidized anodized aluminum and the corroded stainless

steel made the building look old and visually displeasing. Ownership

specified that we clean and restore the anodized aluminum and stainless

steel panels to like new. We were able to remove the corrosion and rust

from the stainless steel and get the oxidation and discoloration off of

the anodized aluminum. Our exterior architectural metal refinishing

systems provided the results our client expected. |

|

|

|

|

|

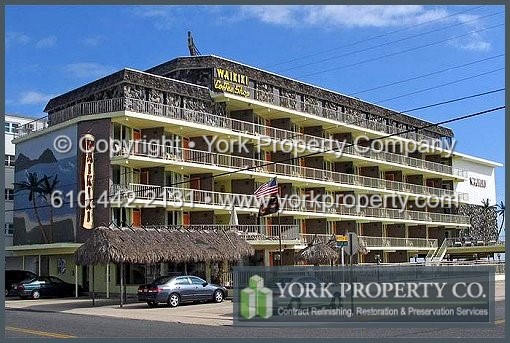

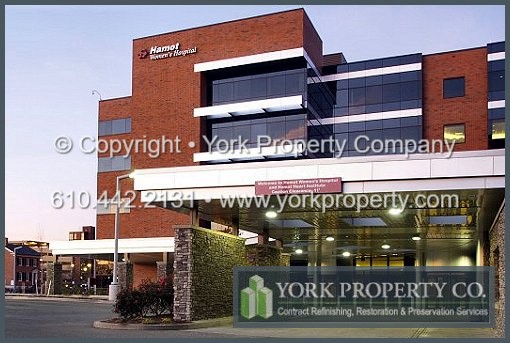

Case Study 43 - Wildwood Crest, New Jersey - Oxidized Anodized Aluminum Restoration

|

|

|

|

>> View Case Study here. |

|

Condition: The oxidized anodized

aluminum window frames, sun damaged anodized aluminum sliding doors and

pitted anodized aluminum railings on this Wildwood Crest, New Jersey

ocean front hotel were stained, faded, corroded, pitted, chemically

etched and oxidized from thirty-two years of exposure to the Atlantic

Ocean salt air, salt water mist and sea spray. Being by the sea the

anodized aluminum was damaged by the sun, UV rays, high humidity, fog

and ocean salt water etching and mineral deposits. The owner wanted to

know how to stop the salt water corrosion, oxidation and salt etching.

York Property Company Solution:

There was excessive anodized aluminum oxidation, corrosion, pitting and

anodic finish failure on the majority of the anodized aluminum

surfaces. Ownership wanted the anodized aluminum to be clean, present

itself well and be protected from the damaging salt in the air. We

restored the aluminum window frames and anodized aluminum sliding glass

doors. Due to pitting and wear and tear the anodized aluminum railings

required painting. With our anodized aluminum painting and restoration

refinishing program the anodized aluminum surfaces are restored and

protected. |

|

|

|

|

|

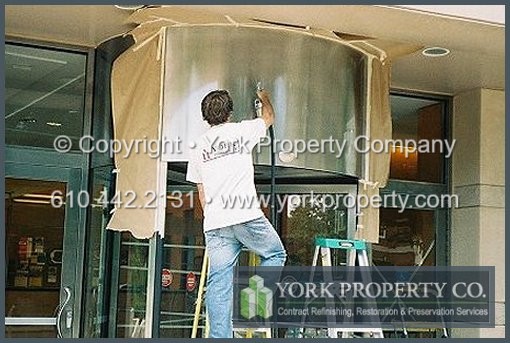

| Case Study 44 - Bethesda, Maryland - Pitted Satin Finish Stainless Steel Refinishing |

|

|

|

>> View Case Study here. |

|

Condition:

The stainless steel clad

revolving door drum, stainless steel revolving doors and stainless

steel swing doors on all twenty-six entrances had oxidized, pitted and

started rusting. The aged, winter salt damaged, sun and UV weathered

and faded lacquer wore out and was cracking, peeling and wearing off

the stainless steel finishes. The exposed stainless steel was rusting

and pitting. The doors and door handles with human contact were

scratched and stained. On-site stainless steel refinishing was required

to remove the scratches and rust from the stainless steel.

York Property Company

Solution: The stainless steel refinishing, stainless steel

repair and stainless steel restoration was completed on the weekend

over many months. After the failed lacquer was removed we got the rust,

corrosion, oxidation, pitting and scratches off the stainless steel

satin finish. We then spray applied a fresh coat of lacquer to protect

the stainless steel from salt, rust, oxidation, pollutants, stains and

wear and tear. The stainless steel revolving doors and stainless steel

entrance doors are now clean, refurbished, restored and reconditioned. |

|

|

|

|

|

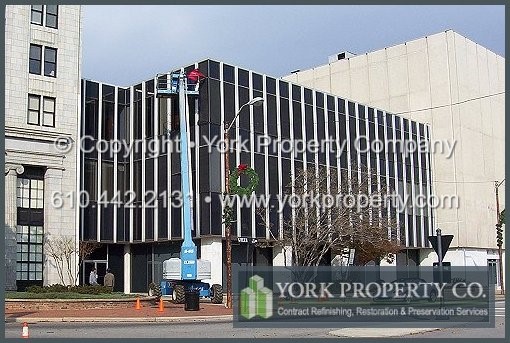

Case Study 45 - Fayetteville, North Carolina - Historical Anodized Aluminum Restoration

|

|

|

|

>> View Case Study here. |

|

Condition:

This anodized aluminum clad historical building in downtown

Fayetteville, North Carolina was being renovated and transformed from a

bank building to a multi-tenant location. The old anodized aluminum

vertical extrusions were discolored, uneven, stained and in need of

anodized aluminum restoration cleaning. The original anodized aluminum

silver color had weathered a whitish gray and the anodized aluminum was

oxidizing.

York Property Company Solution:

The General Contractor contracted us as oxidized and stained anodized

aluminum refinishing experts to repair the anodized aluminum surface

damage and remove the anodized aluminum oxidation. As specialists in

historical anodized aluminum restoration we refurbished the old, gray

and degraded anodized aluminum to a renewed, clean and protected

condition. |

|

|

|

|

|

| Case Study 46 - Erie, Pennsylvania - Scratched Anodized Aluminum Window Frame Refinishing |

|

|

|

>> View Case Study here. |

|

Condition:

The bronze anodized aluminum window mullions, anodized aluminum doors

and frames and anodized aluminum window frames on this commercial

building in Erie, Pennsylvania were damaged, scratched and stained

during the anodized aluminum curtain wall installation. The owner and

General Contractor thought the only option was to paint the damaged

anodized aluminum. We informed them that we could clean, refurbish and

recondition the contaminated, scarred and degraded anodized aluminum

surface finishes to original condition.

York Property Company Solution:

As stained anodized aluminum cleaning, scratched anodized aluminum

refinishing and damaged anodized aluminum restoration experts we were

contracted to remove the surface scratches and blemishes from the brown

colored bronze anodized aluminum surfaces. When the anodized aluminum

scratch removal program and anodized aluminum restoration project was

complete the anodized aluminum finishes looked renewed. The anodized

aluminum had the original luster and sheen and was in like new

condition. |

|

|

|

|

|

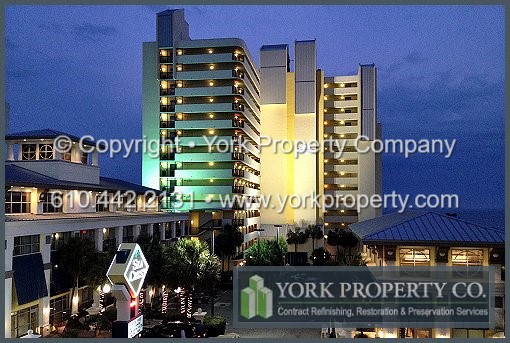

Case Study 47 - Myrtle Beach, South Carolina - Oxidized Anodized Aluminum Restoration

|

|

|

|

>> View Case Study here. |

|

Condition:

The anodized aluminum window frames on this luxury resort in

Myrtle Beach, South Carolina had weathered and oxidized due to being

exposed to the ocean front elements for twenty-five years. The Resort

Management was displeased with the condition of the anodized aluminum

window

frames and for aesthetic considerations was looking for a restoration

cleaning solution. Cleaning and refurbishing the anodized

aluminum window frames was less expensive than painting and achieved

the same

result of revitalizing the anodized finishes factory gloss, color and

sheen.

York Property Company Solution:

A York Property Company Technical Advisor assisted the Consulting

Engineering firm

with the anodized aluminum surface damage analysis and the correct

oxidized anodized aluminum cleaning and refinishing specification for

the cleaning and restoration of the weathered, faded and

discolored anodized aluminum window frames. As oxidized anodized aluminum window

frame restoration contracting specialists, we analyzed the anodized

aluminum window frames, conducted tests and prepared remedial anodized

aluminum cleaning and maintenance specification documents. With the

findings of our analysis and anodized aluminum remedial maintenance

washing specification an anodized aluminum cleaning and washing program

was implemented over the course of the winter when the resort was closed. |

|

|

|

|

|

| Case Study 48 - Toronto, Ontario - Restoring Oxidized Painted Aluminum Facade Panels |

|

|

|

>> View Case Study here. |

|

Condition:

The original clear coat factory finish on the painted aluminum clad

building facade siding panels on this commercial building in Toronto,

Ontario had failed due to age, ultraviolet sun damage and a lack of

maintenance washing. The paint finish was chalking, faded, oxidized and

had lost its luster and sheen. The owner could paint the building at

great expense or wash, renovate and rejuvenate the original blue

painted aluminum metal clad panels. Cleaning and renovating the factory

paint finish was the most cost effective.

York Property Company Solution:

As painted aluminum metal restoration specialists we cleaned, restored

and rejuvenated the faded painted aluminum without further damaging the

painted surface. We cleaned, repaired and restored the damaged and

oxidized painted aluminum siding panels with our faded paint cleaning

and restoration system. After cleaning and refinishing the painted

aluminum building facade siding the panels were clean, protected and as

good as new. |

|

|

|

|

|

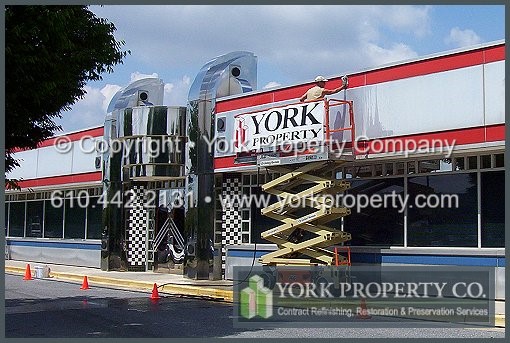

Case Study 49 - Gaithersburg, Maryland - Refurbishing Stained Anodized Aluminum Panels

|

|

|

|

>> View Case Study here. |

|

Condition:

The exterior clear anodized aluminum siding panels on this

entertainment facility in Gaithersburg, Maryland were faded, stained,

dull and oxidized. Our client had not washed the silver gray colored

anodized aluminum clad siding panels since they were new. The anodized

aluminum siding aged from exposure to pollutants, acid rain, the sun,

hard water spots and caustic mineral deposits. The lack of anodized

aluminum washing, care or maintenance caused the anodized aluminum

metal finish to prematurely bleach, corrode, stain, pit and oxidize.

Management saw the results of not caring for, maintaining or washing

the anodized aluminum cladding and contacted us for our anodized

aluminum restoration and preservation expertise.

York Property Company Solution:

Our anodized aluminum Technical Consulting Division was contracted to

analyze the degraded exterior anodized aluminum panels and metal

finishes. We found excessive staining, corrosion, oxidation and anodic

finish failure on the majority of the anodized aluminum surfaces. With

the findings of our anodized aluminum surface testing and analysis we

informed our client that the anodized aluminum finishes could be

cleaned and restored and did not require painting. A long-term anodized

aluminum cleaning, anodized aluminum washing and anodized aluminum

maintenance program was initiated to restore, protect and preserve the

anodized aluminum clad siding. When the anodized aluminum cleaning,

repair, restoration and protection program was complete the anodized

aluminum clad siding panels looked clean, fresh and new. |

|

|

|

|

|

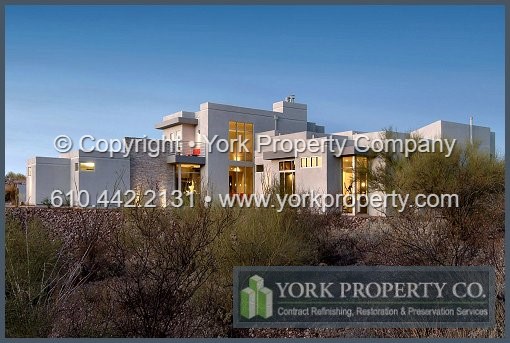

| Case Study 50 - Tucson, Arizona - Repairing Acid Etched Anodized Aluminum Windows |

|

|

|

>> View Case Study here. |

|

Condition:

The new clear anodized aluminum factory finish was stained and etched

during the construction of this Tucson, Arizona custom home. During

construction acidic stucco particles landed on the anodized aluminum

window frames and

anodized aluminum doors. The anodized finish was acid

etched and oxidized. The G.C. contracted us to get the stucco debris

off and get the

acid etching stains out of the anodized aluminum surfaces. As acid

burned

anodized aluminum cleaning and chemically etched anodized aluminum

refinishing experts, our client had confidence we could refinish and

restore the damaged anodized aluminum surface finishes.

York Property

Company Solution:

We repaired the damaged anodized aluminum

surfaces with our acid etched

anodized aluminum restoration cleaning and oxidized anodized aluminum

reconditioning system. We had to remove the stucco debris while refinishing the

anodized aluminum without causing any more damage to the thin anodized

anodic finish. Although the anodized aluminum building facade window

mullions and doors were seriously damaged, our anodized aluminum

construction restoration cleaning program allowed us

to restore the acid etched and oxidized

anodized aluminum to "like new". |

|

|

|

|

|

|

|

York

Property Company provides

professional oxidized anodized aluminum corrugated cladding

restoration, faded anodized aluminum siding panel refinishing and mold

stained anodized aluminum spandrel panel system maintenance services

that restore the color, gloss, luster, sheen and visual appearance.

Our

highly trained company

technicians clean, repair, refinish and restore anodized aluminum,

painted aluminum and stainless steel finishes on-site.

Ask an Expert: Contact the metal building facade cleaning and refinishing experts today at 610.442.2131

and request a comprehensive analysis of your building's weathered,

old, deteriorated

and damaged exterior metal finishes.

Schedule a Site Visit: Our industry-leading,

skilled, experienced and knowledgeable technical consultants will

specify a customized long-lasting and cost-effective

stained anodized aluminum building facade panel cleaning, rusting

stainless steel cladding refinishing and aged anodized aluminum

curtain wall panel refurbishing specification that will beautify,

recondition, improve, restore and protect all your architectural metal

finishes. |

|

|

|

|

|

|

| United States:

Alabama, Alaska, Arizona, Arkansas, California, Colorado, Connecticut,

Delaware, Florida, Georgia, Hawaii, Idaho, Illinois, Indiana, Iowa,

Kansas, Kentucky, Louisiana, Maine, Maryland, Massachusetts, Michigan,

Minnesota, Mississippi, Missouri, Montana, Nebraska, Nevada, New

Hampshire, New Jersey, New Mexico, New York, North Carolina, North

Dakota, Ohio, Oklahoma, Oregon, Pennsylvania, Rhode Island, South

Carolina, South Dakota, Tennessee, Texas, Utah, Vermont, Virginia,

Washington, West Virginia, Wisconsin and Wyoming. |

|

| Canada: Alberta, British Columbia, Manitoba, Ontario, Quebec and Saskatchewan. |

|

|

|

|

|