|

|

|

>>1-10 >>11-20 >>21-30 >>31-40 >>41-50 >>51-60 >>61-70 >>71-80 >>81-90 >>91-100

|

|

|

York Property Company

provides proven metal building facade cleaning, refinishing and

restoration solutions for weathered anodized aluminum wall panels, faded painted aluminum

curtain wall mullions and uneven stainless steel storefront window frame finishes. At York Property Company we emphasize the distinction between what can be done and what needs to be done.

Attention to detail is the hallmark of the York Property Company experience.

|

|

|

|

Have a Question? Ask Us: Contact the metal building facade and metal curtain wall cleaning, refinishing and restoration professionals today at 647.204.5381 for nationwide service in the United States and Canada.

The York Property Company technical staff

has decades of experience in damaged metal building facade problem identification and causes with

the field experience, knowledge and expertise to provide the correct and most

appropriate metal cleaning, refinishing and restoration specification to suit the needs of the subject property; we plan, specify and enable solutions.

Our quality control standards, thoroughly trained field crews and constant field supervision ensure our Class A client building owners and managers optimum results with each York Property Company project. |

|

|

|

|

|

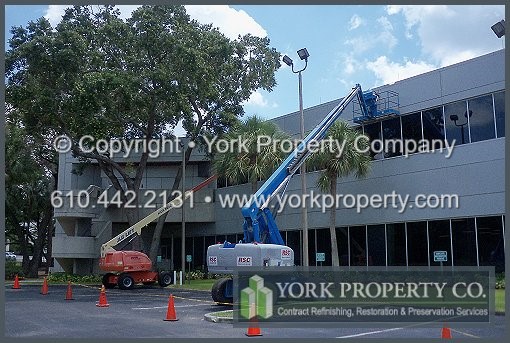

Case Study 1 - Tampa, Florida - Stained Anodized Aluminum Panel Restoration

|

|

|

|

|

>> View Case Study here.

|

|

Condition:

The exterior oxidized clear anodized aluminum building facade panels

and stained anodized aluminum window frames on this owner occupied ADP,

Inc. commercial office building in Tampa, Florida were faded,

weathered, bleach, sun and UV damaged. As well, the discolored ground

floor anodized aluminum panels were stained with calcium, hard water

stains and mineral deposits from the sprinkler system. The exterior

natural colored anodized aluminum was not clean and the owners required

the anodized aluminum siding panels and extrusions be refinished and

restored. The oxidized anodized aluminum refinishing project would

renew the anodized aluminum finishes to the original factory anodized

aluminum gloss, color and sheen.

York Property Company

Solution: Our anodized aluminum Technical Consulting Division

was contracted to analyze the faded, sun damaged and stained silver

grey anodized aluminum clad siding panels and bleached anodized

aluminum window mullions. With an analysis of the damaged anodized

aluminum finishes a long-term anodized aluminum cleaning, washing and

maintenance program was implemented to clean, refurbish, preserve and

protect the oxidized anodized aluminum clad siding and mineral stained

anodized aluminum window frames. When the anodized aluminum was

restored by our field technicians the anodized aluminum building

extrusions looked as new as the original date of installation. |

|

|

|

|

|

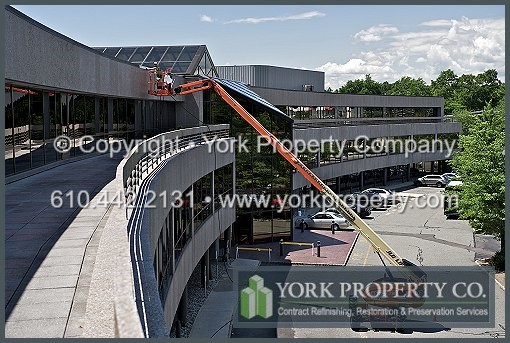

Case Study 2 - Park Ridge, New Jersey - Acid Etched Anodized Aluminum Restoration

|

|

|

|

>> View Case Study here.

|

|

Condition:

A lack of washing the exterior dark bronze anodized aluminum cladding,

siding panels and window frames on this twenty-three year old owner

occupied commercial building in Park Ridge, New Jersey caused the anodized

aluminum to bleach, stain, acid etch and oxidize. Without washing the

anodized aluminum it aged from exposure to airborne and waterborne

contaminants, pollutants, acid rain, sun damage and UV exposure. The

lack of maintenance washing contributed to the corrosion and pitting on

the anodized metal finishes. Ownership had not followed the anodized

aluminum manufacturers washing and preventive maintenance schedule

since the anodized aluminum was new.

York Property Company Solution:

Sartak Holdings realized that anodized aluminum washing and

maintenance was vital to maintain the twenty-three year old anodized

finish over the long-term. We were contacted to analyze the degraded,

stained, corroded, pitting and oxidized exterior bronze anodized

aluminum mullions, window frames, siding and cladding panels. With the

findings of our analysis and specification we were contracted to clean,

wash, refinish and maintain the contaminated anodized aluminum

finishes. Our anodized aluminum cleaning and refinishing system

cleaned, refurbished and protected the anodized aluminum restoring the

original color, gloss and sheen to the bronze anodized finish. |

|

|

|

|

|

| Case Study 3 - San Jose, California - Dirty Stainless Steel Cladding Restoration |

|

|

|

>> View Case Study here.

|

|

Condition:

The Type 316 exterior stainless steel curtain wall metal cladding

panels on this San Jose, California entertainment complex had degraded

from ten years of exposure to the sun, waterborne and airborne

contaminants and pollutants. The stainless steel cladding was dirty,

stained, oxidized, pitting, rusting and corroded. Ownership wanted the

curtain wall stainless steel cladding panels clean, repaired and

refurbished.

York Property

Company Solution:

As stainless steel metal cladding and curtain wall metal restoration

specialists we specified the correct stainless steel restoration

cleaning methods and

materials and were contracted to restore the stainless steel clad

curtain wall to the original luster for the building's ten year

anniversary. The stainless steel panels are now clean, repaired and

protected from any further environmental damage. |

|

|

|

|

|

Case Study 4 - Bronx, New York - Restoring Caulking Stained Anodized Aluminum Panels

|

|

|

|

>>

View Case Study here. |

|

Condition: The clear anodized aluminum panels on the exterior of the VA Hospital

in Bronx, New York had degraded from forty years of exposure to

airborne and waterborne contaminants. The anodized aluminum clad panels

were dirty, stained and discolored showing its age. The petroleum-based

window gaskets and silicone caulking had degraded leaching an oily

residue on the surface of the clear anodized aluminum. Until management

worked with us, they could not find anyone to clean, refinish and

restore the damaged anodized aluminum building facade panels. Our

client, the United States Department of Veterans Affairs, wanted the

silver colored anodized aluminum clad building clean, restored and the

black stains and silicone caulking residue removed.

York Property Company Solution:

We worked with Fellenzer Engineering LLP of Middletown, New York on the

anodized aluminum surface damage analysis and the correct anodized

aluminum cleaning and refinishing specification for the cleaning,

restoration and protection of the clear anodized aluminum panels. The

dirty, weathered and stained anodized aluminum cleaning posed many

challenges. As the building is a hospital, we had to be sensitive to

the doctors, patients and pedestrians within and around the facility.

Our decades of anodized aluminum refinishing expertise allowed our

on-site field technicians to clean and restore the silver colored

anodized aluminum surface finishes. Our anodized aluminum spray applied

protective lacquer coating sealed the pores of the anodic finish. The

forty-year-old anodized aluminum finish now has the original sheen,

natural color and luster. |

|

|

|

|

|

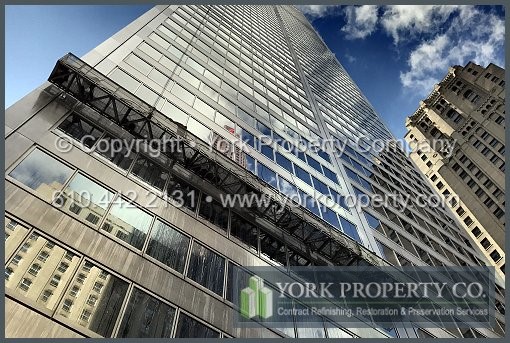

Case Study 5 - Toronto, Ontario - Weathered Stainless Steel Curtain Wall Restoration

|

|

|

|

>> View Case Study here.

|

|

Condition:

Commerce Court West, designed by world-renown architect I. M. Pei, lies

in the heart of Toronto, Ontario's downtown financial district. When

constructed in 1972, the 57-storey tower was at the time the largest

stainless steel clad building in North America and the tallest building

in Canada. As the years passed, the stainless steel cladding on the

tower became visually displeasing with rust, pitting, dirt and stains.

The color, sheen and luster on the exterior metal panels had been lost

due to pollutants such as automobile exhaust, acid rain, winter salt

and other waterborne and airborne contaminants. A solution was sought

to restore the stainless steel exterior of the prestigious bank tower

in order to return the building to its former glory. This is when York

Property Company accepted the challenge of performing the work

necessary, providing the precision and skill, that would reclaim the

beauty of one of Toronto's crown-jewels.

York Property Company Solution:

The stainless steel was rusting, pitting, oxidized and extremely

stained. As stainless steel metal reconditioning and refinishing

experts, QuadReal Property Group had confidence we could clean, refurbish, resurface

and restore the stainless steel clad panels and window frames. The

stainless steel restoration cleaning project posed many challenges. The

building is 800 feet tall and working from that height was complex due

to the wind. Our

stainless steel refinishing and restoration system allowed us to clean

and restore the corroded stainless steel metal panels back to the

original sheen, finish and color. |

|

|

|

|

|

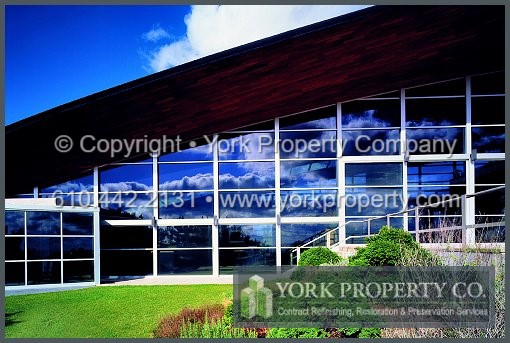

| Case Study 6 - East Hampton, New York - Restoring Acid Etched Anodized Aluminum Windows |

|

|

|

>> View Case Study here.

|

|

Condition:

The clear anodized aluminum entrance doors and anodized aluminum

storefront window frames on this multi-million dollar East Hampton, New York

estate were damaged, stained, oxidized and acid etched by a contractor

acid cleaning the teak soffit above the anodized aluminum window frame

extrusions. The acidic restoration cleaning agent flash etched and

burned all of the building facade clear anodized aluminum. The milky

white chemical staining left the silver metallic anodized aluminum

damaged beyond traditional anodized aluminum cleaning methods.

York Property

Company Solution:

The owner of the property with exacting standards demanded a remedy to

clean, repair and restore the clear anodized aluminum window frames and

doors to the original satin brushed finish. The three storey acid

etched anodized aluminum residential building facade storefront was

repaired and restored to the original color and sheen specification

with our anodized aluminum construction cleaning and restoration system. |

|

|

|

|

|

Case Study 7 - Raleigh, North Carolina - Refurbishing Oxidized Anodized Aluminum Panels

|

|

|

|

>> View Case Study here. |

|

Condition:

The exterior clear anodized aluminum panels on the North Carolina

Museum of Art in Raleigh, North Carolina were faded, stained,

discolored

and oxidized. Our client, the State of North Carolina, had not remedial

maintenance washed the

anodized aluminum clad panels since they were

new. The anodized aluminum panel finishes aged and degraded from

exposure to caustic pollutants, acid rain, the sun, hard water spots

and caustic calcium mineral deposits. The lack of anodized aluminum

washing, care or maintenance caused the anodized aluminum metal finish

to prematurely bleach, corrode, stain, pit and oxidize. Facility

management saw the results of not caring for,

maintaining or washing the anodized aluminum panels and

contacted us for our anodized aluminum restoration and preservation

expertise.

York Property Company Solution:

Our anodized aluminum Technical Consulting Division was contracted to

analyze the degraded exterior anodized aluminum Class

I clear anodic finishes. We found excessive staining, corrosion,

oxidation and anodic finish failure on the majority of the anodized

aluminum panel surfaces. With the findings of our anodized

aluminum surface testing and analysis a long-term anodized aluminum

cleaning, washing and maintenance program was initiated to restore,

protect and preserve the clear anodized aluminum panel system. When

the anodized aluminum panel cleaning, repair, restoration and

protection program was complete the anodized aluminum clad panels

looked clean, fresh and new with the original factory gloss and

sheen. |

|

|

|

|

|

Case Study 8 - Neenah, Wisconsin - Oxidized Bronze Anodized Aluminum Panel Restoration

|

|

|

|

>> View Case Study here. |

|

Condition:

A lack of remedial maintenance washing of the exterior dark bronze

anodized aluminum clad panels at Kimberly-Clark's office campus in Neenah, Wisconsin caused the

brown anodized aluminum panels to bleach, stain, acid

etch and oxidize. As the anodized aluminum panels were never

washed or polished they aged from exposure to airborne and waterborne

contaminants, pollutants, acid rain, sun damage and UV exposure. The

lack of maintenance washing contributed to the corrosion and stains on

the bronze anodized aluminum metal finishes. Ownership had not followed

the original anodized aluminum manufacturers washing and preventive

maintenance schedule since the anodized aluminum panels were new.

York Property Company Solution:

Jones Lang LaSalle, building management, realized that anodized aluminum panel

washing and maintenance was vital to maintain the thirty-three year old

bronze anodized aluminum anodic finish over the long-term. We were

contacted to analyze the degraded, stained, corroded, weathered and

oxidized exterior bronze anodized aluminum cladding panels. With the findings of our analysis and

specification we were contracted to clean and refinish the contaminated bronze anodized aluminum finishes. Our anodized

aluminum cleaning and refinishing system cleaned, refurbished and

protected the anodized aluminum panels, restoring the

original natural brown color, gloss and sheen to the bronze anodized

finish. |

|

|

|

|

|

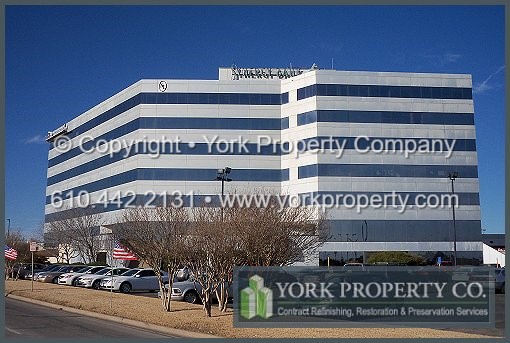

Case Study 9 - Waco, Texas - Stained Anodized Aluminum Panel Restoration

|

|

|

|

>> View Case Study here. |

|

Condition: The clear anodized

aluminum Alucobond panels on this commercial building in Waco, Texas

were painted after they were installed on the building. The silver grey

paint coating on the anodized aluminum was peeling and the old,

brittle, flaking paint had to be removed. Specialty Property wanted the

anodized aluminum clad panels to be restored to the original luster of

new anodized aluminum. If the anodized aluminum was not coated once it

was clean and refurbished the anodized aluminum would bleach, stain,

acid etch and oxidize. To maintain the integrity of the Alucobond

anodic finish ownership requested the anodized aluminum building facade

siding panels be coated and protected with the York Property Company

anodized aluminum protective coating.

York Property Company Solution:

To refurbish and recondition the old, faded and contaminated anodized

aluminum we had to strip the paint off the anodized aluminum finish

without damaging the anodic layer. Removing the paint was time

consuming and required our skill, expertise and experience as anodized

aluminum restoration specialists. If the Alucobond panels were acid

etched or scratched the anodized aluminum would have to be painted

again. The anodized aluminum reconditioning program got the paint off

of the panels safely and refurbished the anodized aluminum color and

finish. The anodized aluminum protective coating enhanced the natural

color and sheen while protecting the anodized aluminum from the sun,

dark grey mineral deposits, milky white calcium stains and caustic

airborne contaminants. |

|

|

|

|

|

| Case Study 10 - Spartanburg, South Carolina - Stained Stainless Steel Panel Restoration |

|

|

|

>> View Case Study here. |

|

Condition:

The exterior stainless steel metal storefront, stainless steel window

frames and stainless steel siding panels on the Adidas, USA building

facade in Spartanburg, South Carolina were stained, rusting, oxidized and bleached from years of

exposure to damaging elements and a lack of routine maintenance

washing. The unsightly damage to the stainless steel panels required

our stainless steel metal refinishing expertise and stainless steel

rust removal program. Our client wanted the caulking and silicone

stained stainless steel repaired, clean and rust free for many years to

come.

York Property Company

Solution: Cleaning and repairing the damaged stainless

steel panels required our years of stainless steel refinishing and

restoration experience. As oxidized stainless steel cleaning and

rusting stainless steel restoration specialists we cleaned and restored

the stainless steel building facade cladding panels with our stainless

steel restoration cleaning, rust and scratch removal systems. This made

the dirty, dull, rusting, faded and corroded building shine. The rust,

staining, pitting, corrosion and oxidation was carefully removed as to

not further damage the satin stainless steel finish on the stainless

steel building facade panels and stainless steel storefront window

frames. |

|

|

|

|

|

|

|

York

Property Company

provides professional oxidized anodized

aluminum window frame cleaning,

faded anodized aluminum clad panel refinishing, stained anodized

aluminum curtain wall restoration and mold and mildew stained anodized

aluminum

building facade refinishing solutions that restore the color, gloss,

luster, sheen and visual appearance.

Our highly trained company

technicians clean, repair, refinish and restore anodized aluminum,

painted aluminum and stainless steel finishes on-site.

Ask an Expert: Contact the metal building facade cleaning and refinishing experts today at 647.204.5381

and request a comprehensive analysis of your building's oxidized,

faded, acid burned

and blemished exterior metal finishes.

Schedule a Site Visit: Our industry-leading,

skilled, experienced and knowledgeable technical consultants will

specify a customized long-lasting and cost-effective

dirty anodized aluminum building facade panel cleaning, oxidized

stainless steel curtain wall panel restoration and faded painted

aluminum

building facade panel refinishing specification that will beautify,

improve, maintain, restore and protect all your architectural metal

finishes.

|

|

|

|

|

|

|

| United States:

Alabama, Alaska, Arizona, Arkansas, California, Colorado, Connecticut,

Delaware, Florida, Georgia, Hawaii, Idaho, Illinois, Indiana, Iowa,

Kansas, Kentucky, Louisiana, Maine, Maryland, Massachusetts, Michigan,

Minnesota, Mississippi, Missouri, Montana, Nebraska, Nevada, New

Hampshire, New Jersey, New Mexico, New York, North Carolina, North

Dakota, Ohio, Oklahoma, Oregon, Pennsylvania, Rhode Island, South

Carolina, South Dakota, Tennessee, Texas, Utah, Vermont, Virginia,

Washington, West Virginia, Wisconsin and Wyoming. |

|

| Canada: Alberta, British Columbia, Manitoba, Ontario, Quebec and Saskatchewan. |

|

|

|

|