|

|

|

| Client Case

Studies: 1-100 I Before

& After Photo Gallery I Client Testimonials I Contact York Property Co |

|

| >>1-10 >>11-20 >>21-30 >>31-40 >>41-50 >>51-60 >>61-70 >>71-80 >>81-90 >>91-100 |

|

|

York Property Company provides proven metal building facade cleaning, refinishing

and restoration solutions for dirty exterior painted aluminum

storefront window frames, weathered stainless steel curtain wall mullions and acid burned anodized aluminum building

facade window frame finishes. At York Property Company we emphasize the distinction between what can be done and what needs to be done.

Attention to detail is the hallmark of the York Property Company experience.

|

|

|

|

Have a Question? Ask Us: Contact the metal building facade and metal curtain wall cleaning, refinishing and restoration professionals today at 647.204.5381 for nationwide service in the United States and Canada.

The York Property Company

technical staff

has decades of experience in damaged metal building facade problem

identification and causes with

the field experience, knowledge and expertise to provide the correct

and most

appropriate metal cleaning, refinishing and restoration specification

to suit the needs of the subject property; we plan, specify and enable

solutions.

Our quality control standards, thoroughly trained field crews and

constant field supervision ensure our Class A client building owners

and managers optimum results with each York Property Company project. |

|

|

|

|

|

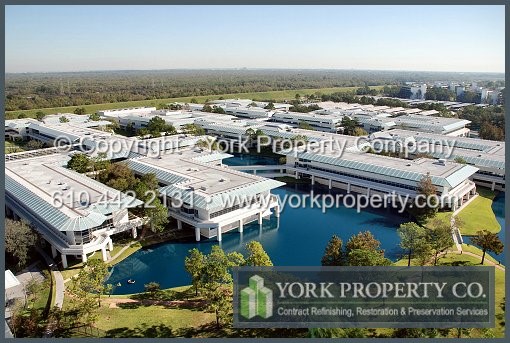

Case Study 31 - Houston, Texas - Sun Damaged Anodized Aluminum Window Restoration

|

|

|

|

|

>> View Case Study here.

|

|

Condition:

The ConocoPhillips Company office park in Houston, Texas was ready for

an extensive building facade restoration. The architectural restoration

specification included restoring all the exterior oxidized anodized

aluminum window mullions, cleaning the dirty anodized aluminum doors

and refinishing the stained anodized aluminum window frames.

York Property Company Solution:

The sixteen building office campus has miles of window mullions.

Without the correct specification to restore the anodized aluminum the

project would be a failure. Our anodized aluminum Technical Consulting

Division was contracted to specify the correct cleaning and refinishing

methods, materials and procedures. |

|

|

|

|

|

| Case Study 32 - Madison, Wisconsin - Restoring Stained Anodized Aluminum Panels |

|

|

|

>> View Case Study here.

|

|

Condition:

The stained clear anodized aluminum metal building facade panels, old

anodized aluminum window frames and deteriorated anodized aluminum clad

column panels were silicone contaminated from leeching and degraded

caulking. The original clear anodized aluminum Duranodic panels on this

commercial building in Madison, Wisconsin were discolored, uneven,

faded and did not match the newly built clean anodized aluminum

stair-tower panels. The aged, faded and weathered original panels with

the silicone caulking staining damage were in need of anodized aluminum

cleaning, repair and restoration.

York Property Company Solution:

To achieve the desired result this project required our silicone

caulking stained anodized aluminum construction cleaning and our faded

and weathered aluminum restoration refinishing system. With these

commercial grade anodized aluminum restoration systems we were able to

clean and repair the staining damage without damaging the silver gray

colored anodized aluminum panels during the restoration process. We

exceeded ownership's expectations as the new clean stair-tower panels

match the original clean and refinished silver metallic panels. |

|

|

|

|

|

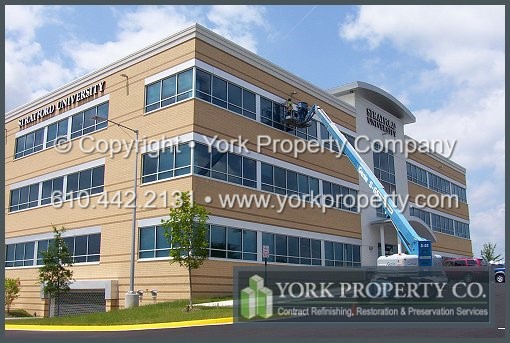

Case Study 33 - Richmond, Virginia - Restoring Acid Etched Anodized Aluminum Panels

|

|

|

|

>> View Case Study here.

|

|

Condition:

The clear anodized aluminum curtain wall panels on this Class "A"

office building in Richmond, Virginia were acid etched when mortar and lime residue leaked

onto the unprotected anodized aluminum surface finishes. An anodized

aluminum construction cleaning contractor used an acid wash to remove

the white stains which further etched the anodized aluminum anodic skin

on the aluminum. The acid wash flash oxidized, chemically etched and

acid burned all of the anodized aluminum window frames and silver

colored anodized aluminum paneling.

York Property Company

Solution: As acid etched anodized aluminum cleaning,

chemical burned anodized aluminum refinishing and oxidized anodized

aluminum restoration experts we were contracted to work on the project.

To clean, restore and protect the anodized aluminum curtain wall panels

we used our anodized aluminum mortar and lime etching removal and

anodized aluminum restoration system. The anodized aluminum surfaces

are now clean, repaired, refurbished and protected from the sun,

weather and further damage. |

|

|

|

|

|

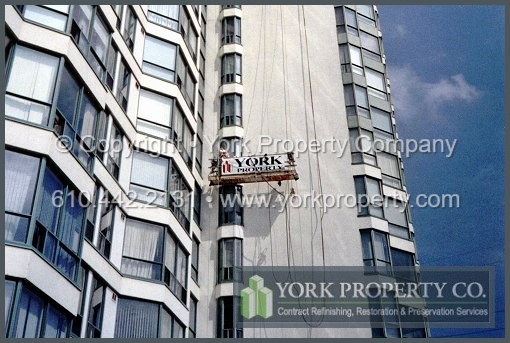

| Case Study 34 - Mississauga, Ontario - Refurbishing Oxidized Painted Aluminum Panels |

|

|

|

>> View Case Study here.

|

|

Condition:

The original green paint coating on the painted aluminum curtain wall

panels, painted aluminum window frames and painted aluminum balcony

railings at this luxury residential condominium in Mississauga, Ontario

had chalked and faded. The paint was damaged, oxidized, stained and

bleached. The condominium owners and management wanted a painted

aluminum curtain wall cleaning, restoration and preservation solution.

York Property Company Solution:

To clean, refurbish and protect the exterior painted surfaces from

further deterioration, we refurbished the curtain wall original paint

finish with our painted aluminum cleaning and restoration system. When

completed the painted aluminum curtain wall panels were clean and

restored to the original condition with renewed luster and sheen. |

|

|

|

|

|

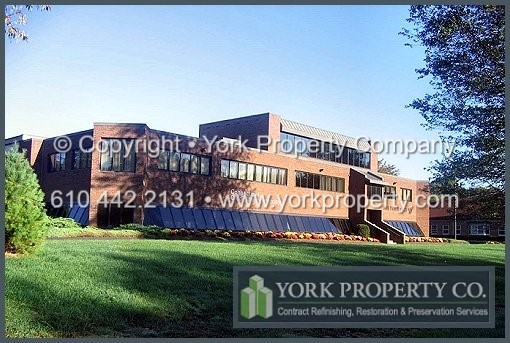

Case Study 35 - New Haven, Connecticut - Corroded Anodized Aluminum Window Refinishing

|

|

|

|

>> View Case Study here.

|

|

Condition:

The exterior anodized aluminum window frames, anodized aluminum

entrance doors and painted aluminum flashing on this commercial building in New Haven, Connecticut were oxidized, pitted,

stained, corroded and chemically etched. The dark bronze anodized

aluminum horizontal window frames were so oxidized the anodic layer had

worn off and the aluminum substrate was exposed. The contaminated

condition of the window frames made the building look weathered. For

long-term preservation the owners required the anodized aluminum be

clean, restored, painted and protected.

York Property Company

Solution: To remove the corrosive contaminants and refurbish the damaged anodized

aluminum we used two different anodized aluminum metal refinishing

systems. We mechanically got the corrosion off and then restoration

cleaned the stained, aged, dull and faded brown anodized aluminum

doors, metal window frames and vertical window mullions. The anodized

aluminum window frames and painted metal flashing that could not be

refurbished or restored were painted to match the color, gloss and

sheen of the restored and reconditioned anodized aluminum window frames. |

|

|

|

|

|

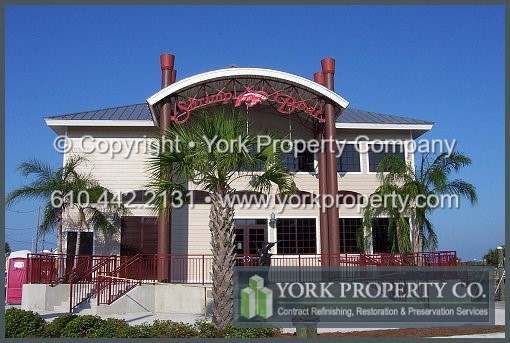

| Case Study 36 - Panama City, Florida - Repairing Stainless Steel Acid Burn Damage |

|

|

|

>> View Case Study here.

|

|

Condition:

The interior Type 304 stainless steel food processing equipment and

stainless steel commercial kitchen appliances at the Shrimp Boat

Restaurant in Panama City, Florida

were scratched, stained, acid etched and damaged by the stainless steel

construction cleaning contractor. Muriatic acid vapor flash rusted all

of the stainless steel surfaces. In an attempt to repair and remove the

rust and damage from the stainless steel the construction cleaning

contractor cross grained and scratched the satin finish on all of the

stainless steel surfaces.

York Property Company

Solution: As acid etched stainless steel refinishing experts, the General Contractor contracted us to repair,

restore and refinish the damaged stainless steel by removing the

scratches and rust from the finishes. We achieved this with our

stainless steel scratch removal and stainless steel rust removal

program to repair and restore the damage to the new stainless steel

surfaces. We removed the scratches, cleaned, repaired, reconditioned

and refinished the damaged stainless steel kitchen appliances and food processing equipment as if they had not been scratched

or damaged. |

|

|

|

|

|

Case Study 37 - Neenah, Wisconsin - Stripping Lacquer off of Anodized Aluminum Panels

|

|

|

|

>> View Case Study here. |

|

Condition:

The dark bronze anodized aluminum building facade panels on this

commercial

building in Neenah, Wisconsin were lacquered after they were installed

on

the building. Over time the lacquer coating on the anodized aluminum

panels got chalky, flaky and started peeling. Cushman & Wakefield wanted the anodized aluminum panels to be restored to the

original luster of new brown colored anodized aluminum. The building is

a Class A facility and the unsightly condition of the building facade

had to be remedied. The old weathered lacquer had to be removed. Due to

our renowned anodized aluminum restoration expertise, our client

contracted us to remove the failing lacquer and return the anodized

aluminum panels to their original condition.

York Property Company Solution:

To refurbish and recondition the weathered and faded anodized aluminum panels we had to chemically strip the lacquer

off the anodized aluminum finish without damaging the brown anodic

layer. Removing the lacquer was time consuming and required our skill,

expertise and experience as commercial anodized aluminum panel

restoration contracting specialists. If the panels were

bleached, burned, acid etched or scratched the anodized

aluminum would have to be replaced. The anodized aluminum

reconditioning program got the lacquer off of the anodized aluminum

panels safely and refurbished the anodized aluminum dark brown

color and satin finish. |

|

|

|

|

|

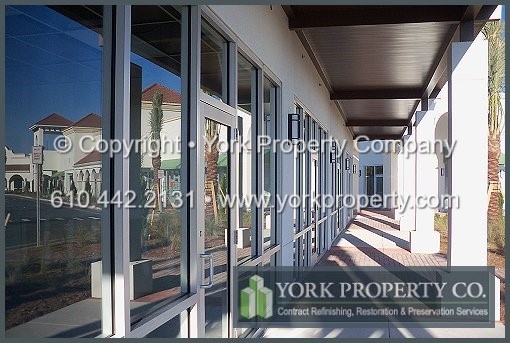

| Case Study 38 - Ft. Myers, Florida - Acid Etched Anodized Aluminum Storefront Cleaning |

|

|

|

>> View Case Study here.

|

|

Condition:

The new Class I clear anodized aluminum storefront window frames and

anodized aluminum doors and frames on this Ft. Myers, Florida strip

mall were acid etched. The factory finished Kawneer anodized aluminum

anodic surface finish got damaged, scratched, blemished and stained

whitish gray with lime contaminated debris, acidic water and stucco

overspray. Concrete, stucco and mortar residue had splashed onto the

unprotected anodized aluminum surfaces. The anodized aluminum new

construction project was compromised by the concrete, stucco and lime

residue, white splatter, scarring, acid burns and anodized aluminum

surface imperfections.

York Property Company

Solution: The General Contractor retained us as an acid

etched anodized aluminum construction cleaning expert to clean, repair

and restore the chemical stained and acid damaged anodized aluminum

storefront window frames and scratched anodized aluminum door frames.

The architect specified that we repair the acid etching damage and

return the anodized aluminum to the original condition. We achieved

this request using our anodized aluminum concrete and mortar removal

construction cleaning restoration system. The natural color anodized

aluminum surfaces are now clean, repaired, refurbished and protected

from further damage. |

|

|

|

|

|

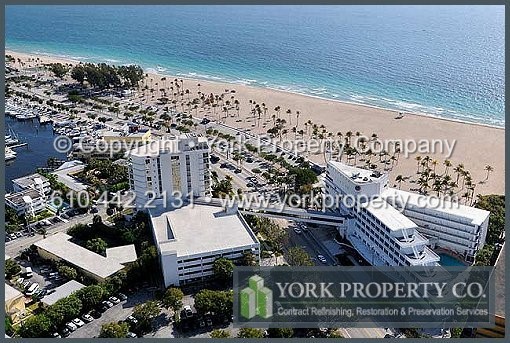

Case Study 39 - Fort Lauderdale, Florida - Refinishing Damaged Anodized Aluminum Windows

|

|

|

|

>> View Case Study here.

|

|

Condition: The oxidized anodized

aluminum window frames, bleached anodized aluminum sliding doors and

sun faded anodized aluminum balcony railings on this Fort Lauderdale, Florida

oceanfront hotel are continually exposed to the sun, UV rays,

humidity, heat, salt water mist and corrosive salt air. In this

damaging and caustic environment the clear natural colored anodized

aluminum metal finishes had weathered, oxidized, pitted and stained.

The original gloss and silver color of the anodized aluminum anodic

finish had faded, bleached and was damaged by salt in the environment.

The new hotel owners saw the results of not washing, caring for or

maintaining the anodized aluminum window mullions and frames, anodized

aluminum sliding glass doors and anodized aluminum railings.

York Property Company Solution:

The new owners required the anodized aluminum continually look new and

clean and not have any oxidation, stains or salt residue contamination.

As anodized aluminum oxidation removal, anodized aluminum pitting and

corrosion removal and anodized aluminum refinishing specialists we

specified the correct cleaning methods and renovation materials. This

anodized aluminum restoration specification enabled the stucco painting

contractor to refurbish the anodized aluminum surface finishes while

the access equipment was on-site. The spray applied lacquer now

protects the anodized aluminum window mullions from salt water damage,

salt air damage, corrosive pollutants, airborne contaminants and salt

water mist associated with an oceanfront hotel. |

|

|

|

|

|

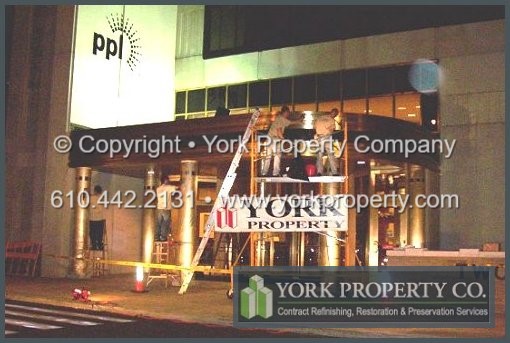

Case Study 40 - Allentown, Pennsylvania - Restoring Oxidized Architectural Metal Doors

|

|

|

|

>> View Case Study here. |

|

Condition:

The brass clad revolving doors, brass columns, brass window frames,

brass panels and brass PPL Utilities sign had oxidized, tarnished and

pitted to the point that brass refinishing was required. The old, sun

damaged, u.v. weathered and faded clear lacquer wore out and was

wearing off, cracking and peeling. The exposed architectural brass

finish was tarnishing, oxidizing, pitting, scratched, stained and

turning green. The brass patina needed to be removed. On-site brass

refinishing and scratch removal was specified to clean, refurbish,

repair and protect the brass surfaces and brass finish.

York Property Company Solution:

The brass refinishing, repair and restoration project was completed at

night and on the weekend. Brass renovation had to get the failed

lacquer off the brass and remove the brown patina, scratches, tarnish

and stains. Brass polishing and brass restoration assisted in removing

the oxidation, corrosion, discoloration and pitting. During the brass

repair we spray applied a fresh coat of lacquer to protect the brass

finish from the damaging elements, pollutants and contaminants. As

brass refinishing experts the brass clad window frames, brass panels,

brass columns, brass revolving doors and brass sign are now clean,

refurbished, rejuvenated, restored and protected. |

|

|

|

|

|

|

|

York

Property Company

provides professional dirty anodized aluminum window frame cleaning,

discolored anodized aluminum clad panel refinishing, weathered anodized

aluminum building facade window frame restoration and sun damaged

anodized aluminum siding panel cleaning solutions that restore the

color, gloss, luster, sheen and visual appearance.

Our highly trained

company

technicians clean, repair, refinish and restore anodized aluminum,

painted aluminum and stainless steel finishes on-site.

Ask an Expert: Contact the metal building facade cleaning and refinishing experts today at 647.204.5381

and request a comprehensive analysis of your building's moldy, stained,

faded

and weathered exterior metal finishes.

Schedule a Site Visit: Our industry-leading,

skilled, experienced and knowledgeable technical consultants will

specify a customized long-lasting and cost-effective

iron oxide rust stained stainless building facade panel chemical

cleaning, faded painted

aluminum building facade panel cleaning and acid etched anodized

aluminum storefront refinishing specification that will refurbish,

improve, maintain, restore and protect all your architectural metal

finishes. |

|

|

|

|

|

|

| United States:

Alabama, Alaska, Arizona, Arkansas, California, Colorado, Connecticut,

Delaware, Florida, Georgia, Hawaii, Idaho, Illinois, Indiana, Iowa,

Kansas, Kentucky, Louisiana, Maine, Maryland, Massachusetts, Michigan,

Minnesota, Mississippi, Missouri, Montana, Nebraska, Nevada, New

Hampshire, New Jersey, New Mexico, New York, North Carolina, North

Dakota, Ohio, Oklahoma, Oregon, Pennsylvania, Rhode Island, South

Carolina, South Dakota, Tennessee, Texas, Utah, Vermont, Virginia,

Washington, West Virginia, Wisconsin and Wyoming. |

|

| Canada: Alberta, British Columbia, Manitoba, Ontario, Quebec and Saskatchewan. |

|

|

|

|

|