|

|

|

| Client Case

Studies: 1-100 I Before

& After Photo Gallery I Client Testimonials I Contact York Property Co. |

|

|

| York

Property Company - Stainless Steel

Cleaning, Refinishing and Restoration |

|

|

Caulking

stained stainless steel panels.

|

|

Refurbished

stainless steel panels.

|

|

|

|

|

|

| >> View the York Property Company

Before

& After Photo Gallery here. <<

|

|

|

|

|

|

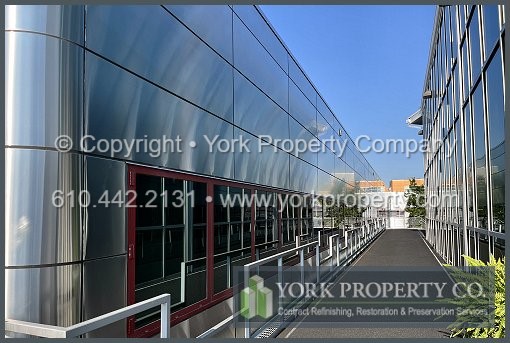

Case Study 61 - Caulking Stained Stainless Steel Building Facade Restoration

|

|

|

|

>> View

Case Study here. |

|

Condition:

This hospital in Chattanooga, Tennessee was built thirty years ago. After

years of exposure the exterior stainless steel building facade panels

were dirty, stained, degraded and contaminated from corrosive and

damaging waterborne and airborne contaminants. Compounding the problem was leaching

plasticizers and silicone from the degraded caulking. There had been no

remedial maintenance washing over the life of the building which

contributed to the severity of the contamination. The hospital is a

Class A facility and the unsightly condition of the building facade had

to be remedied. Due to our renowned stainless steel restoration

expertise, our client contracted us to remove the contaminants and

caulking residue returning the stainless steel panels to their original

condition. This stainless steel cleaning program will leave the stainless steel building facade

clean and contaminant free for many years to

come.

York Property Company

Solution:

Cleaning and repairing the damaged and dirty stainless

steel panels required our years of oxidized stainless steel refinishing

and

caulking stained stainless steel restoration experience. As stainless

steel building facade cleaning and stainless steel restoration

specialists we restoration cleaned

the stainless steel building facade cladding panels with our dirty

stainless

steel restoration cleaning and caulking stained refinishing systems.

This program made

the dirty, oxidized and stained building facade panels shine. The

staining, corrosion and silicone caulking residue was expertly removed

as to

not further damage the satin stainless steel finish on the stainless

steel building facade panels. |

|

|

|

|

|

Case Study 36 - Oxidized, Stained and

Rusting Stainless Steel Refinishing

|

|

|

|

|

>> View

Case Study here.

|

|

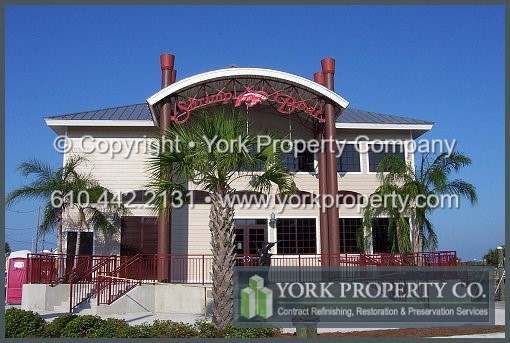

Condition:

The interior Type 304 stainless steel food processing equipment and

stainless steel commercial kitchen appliances at the Shrimp Boat

Restaurant in Panama City, Florida

were scratched, stained, acid etched and damaged by the stainless steel

construction cleaning contractor. Muriatic acid vapor flash rusted all

of the stainless steel surfaces. In an attempt to repair and remove the

rust and damage from the stainless steel the construction cleaning

contractor cross grained and scratched the satin finish on all of the

stainless steel surfaces.

York Property

Company

Solution: As acid etched stainless steel refinishing experts, the General Contractor contracted us to repair,

restore and refinish the damaged stainless steel by removing the

scratches and rust from the finishes. We achieved this with our

stainless steel scratch removal and stainless steel rust removal

program to repair and restore the damage to the new stainless steel

surfaces. We removed the scratches, cleaned, repaired, reconditioned

and refinished the damaged stainless steel kitchen appliances and food processing equipment as if they had not been scratched

or damaged. |

|

|

|

|

|

| Case Study 5 - Corroded Stainless Steel Curtain Wall Restoration Cleaning |

|

|

|

>> View

Case Study here.

|

|

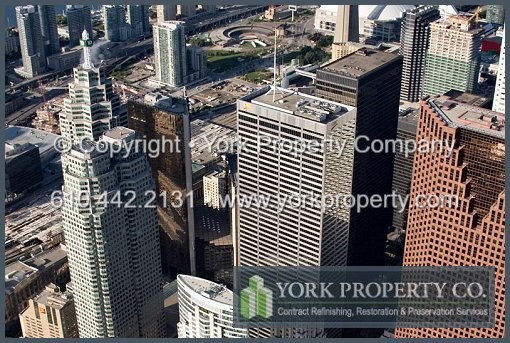

Condition:

Commerce Court West, designed by world-renown architect I. M. Pei, lies

in the heart of Toronto, Ontario's downtown financial district. When

constructed in 1972, the 57-storey tower was at the time the largest

stainless steel clad building in North America and the tallest building

in Canada. As the years passed, the stainless steel cladding on the

tower became visually displeasing with rust, pitting, dirt and stains.

The color, sheen and luster on the exterior metal panels had been lost

due to pollutants such as automobile exhaust, acid rain, winter salt

and other waterborne and airborne contaminants. A solution was sought

to restore the stainless steel exterior of the prestigious bank tower

in order to return the building to its former glory. This is when York

Property Company accepted the challenge of performing the work

necessary, providing the precision and skill, that would reclaim the

beauty of one of Toronto's crown-jewels.

York Property

Company Solution:

The stainless steel was rusting, pitting, oxidized and extremely

stained. As stainless steel metal reconditioning and refinishing

experts, QuadReal Property Group had confidence we could clean, refurbish, resurface

and restore the stainless steel clad panels and window frames. The

stainless steel restoration cleaning project posed many challenges. The

building is 800 feet tall and working from that height was complex due

to the wind. Our

stainless steel refinishing and restoration system allowed us to clean

and restore the corroded stainless steel metal panels back to the

original sheen, finish and color. |

|

|

|

|

|

| Case Study 82 - On-Site Exterior Stainless Steel Sign Refinishing |

|

|

|

>> View

Case Study here. |

|

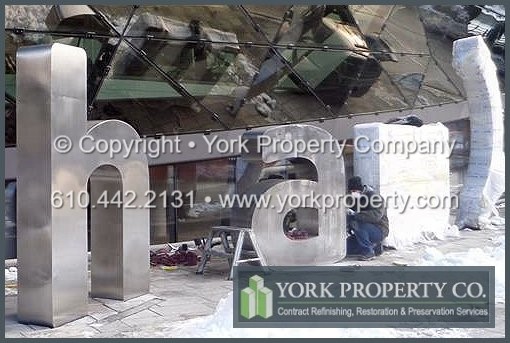

Condition:

During the renovation and restoration of the Shaw Centre in Ottawa,

Ontario a new street sign was specified as part of the overall project.

A Vancouver, British Columbia fabricator fabricated the stainless steel letters for

the sign and had them shipped unfinished to Ottawa. After the letters

were installed the specification required an imparted #4 brushed

finish. Our firm was contracted to mobilize on-site as the preferred

stainless steel refinishing contractor.

York Property Company Solution:

This project was on a tight deadline. As soon as the letters were

installed the York Property Company technicians starting working. The

specification had us installing a #4 architectural finish; also known

as a brushed, directional or satin finish. Even with the freezing

temperatures, the stainless steel was refinished as required. When the

graining was complete, all the stainless steel sign surfaces looked

new, bright, shiny and were free of welding and fabrication sanding

scratches. |

|

|

|

|

|

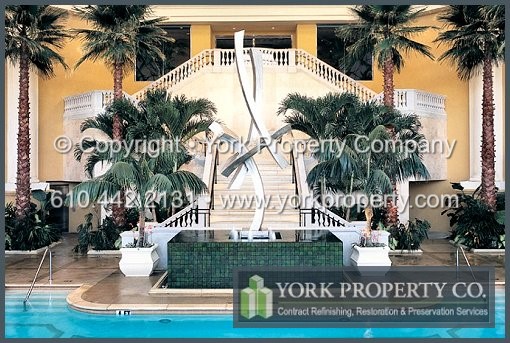

| Case Study 18 - Removing Rust and Corrosion from Stainless Steel Statues |

|

|

|

>> View

Case Study here. |

|

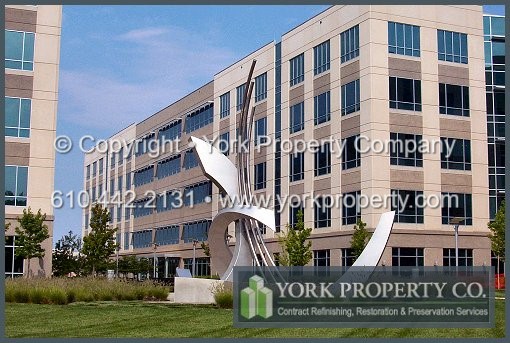

Condition: After a few

years of

exposure to the sun and rain; rust, corrosion, oxidation and staining

had overtaken the stainless steel statue finishes. A lack of stainless

steel maintenance washing allowed the stainless steel finishes to

weather, get damaged, corrode, oxidize and rust. The original stainless

steel gloss and sheen had worn off and the stainless steel statues had

a layer of corrosion that was unacceptable to the sculptor. The

stainless steel statues needed to be renewed, polished and refinished

to make the stainless steel statues shine with the original stainless

steel satin finish and luster.

York

Property Company Solution:

We were contracted by the sculptor to analyze the sun damaged, rusting

and stained stainless steel statue finishes. With our analysis, testing

and stainless steel remedial maintenance report the sculptor was able

to implement a national long-term stainless steel cleaning, washing and

maintenance program to clean, refurbish and protect the stainless steel

finishes. The stainless steel surface rust, corrosion and staining was

effectively removed and the statues are now clean, restored and

protected. |

|

|

|

|

|

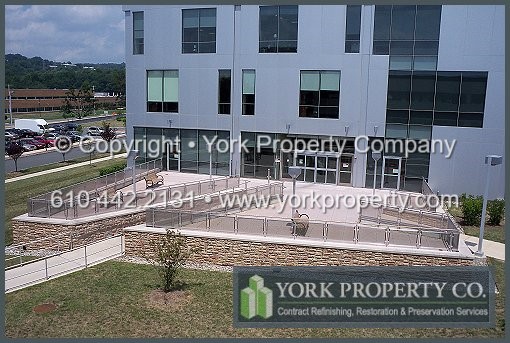

Case Study 79 - Cleaning Weathered Stainless Steel Building Facade Panels

|

|

|

|

>> View

Case Study here. |

|

Condition:

The Hospice Care Center is affiliated with the Siskin Hospital in Chattanooga, Tennessee. After

years of exposure the exterior stainless steel building facade panels

were dirty, stained, degraded and contaminated from corrosive and

damaging waterborne and airborne contaminants. Compounding the problem was leaching

plasticizers and silicone from the degraded caulking. There had not been any

remedial maintenance washing over the life of the building which has

contributed to the severity of the contamination. The hospital is a

Class A facility and the unsightly condition of the stainless steel building facade had

to be remedied. Due to our renowned stainless steel restoration

expertise, our client contracted us to remove the contaminants and

caulking residue returning the stainless steel panels to their original

condition. This stainless steel cleaning program will leave the stainless steel building facade

clean and contaminant free for many years to

come.

York Property Company

Solution:

Cleaning and repairing the damaged and dirty stainless

steel panels required our years of oxidized stainless steel refinishing

and

caulking stained stainless steel restoration experience. As stainless

steel building facade cleaning and stainless steel restoration

specialists we restoration cleaned

the stainless steel building facade cladding panels with our dirty

stainless

steel restoration cleaning and caulking stained refinishing systems.

This program made

the dirty, oxidized and stained building facade panels shine. The

staining, corrosion and silicone caulking residue was expertly removed

as to

not further damage the satin stainless steel finish on the stainless

steel building facade panels. |

|

|

|

|

|

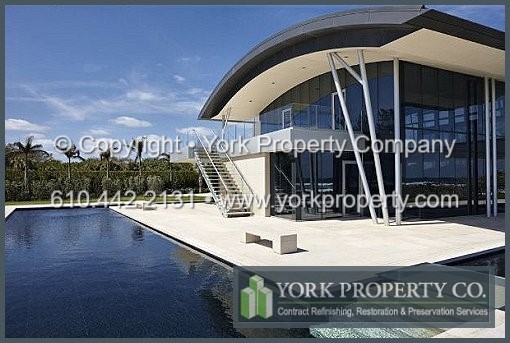

Case Study 58 - Restoring and Protecting

Rusting Stainless Steel Finishes

|

|

|

|

>> View

Case Study here.

|

|

Condition:

The stainless steel window frames and stainless steel doors on this new

Jupiter Island, Florida oceanfront residence are continually exposed to

the sun, humidity, heat, damaging salt water mist and corrosive salt

air. All of these acidic, corrosive and caustic elements are a recipe

for rust, oxidation and corrosion if left on the surface of the

stainless steel. In this damaging and corrosive environment the

stainless steel finish will stain, oxidize, tarnish, pit and rust in a

matter of months. The owners wanted a stainless steel cleaning,

stainless steel washing and stainless steel maintenance specification

to keep the stainless steel window frames and stainless steel doors

from staining, pitting and rusting.

York Property

Company Solution:

They required that the stainless steel clad finishes continually look

new, clean and rust free. As stainless steel rust removal, stainless

steel cleaning and stainless steel restoration specialists we specified

the correct cleaning methods and materials to enable the on-site

maintenance staff to keep the exterior stainless steel window frames

and stainless steel doors clean, protected, stain and rust free from

the caustic environmental elements, salt air, corrosive waterborne and

abrasive airborne pollutants and contaminants associated with an

oceanfront residence. |

|

|

|

|

|

| Case Study 56 - Repairing Damaged Stainless Steel Building Facade Panels |

|

|

|

>> View

Case Study here. |

|

Condition:

This particular 5-storey building is a hospital in Chattanooga,

Tennessee. After

years of exposure to corrosive and damaging waterborne and airborne

contaminants the exterior stainless steel building facade panels

were stained, weathered and visually displeasing. The color, sheen and

luster on the stainless steel panels had faded and a solution was

sought to restore the stainless steel to the original luster.

Unfortunately, our client hired a contractor that used the incorrect

methods and materials, a high speed polishing wheel with an abrasive

cutting compound, that scratched the panels leaving uneven abrasion

marks. Regrettably, the contractor did not stop after one panel, the

damage was not noticed until the entire wall was completed leaving an

enormous amount of damage that had to be repaired. It took more than

two years to settle with the contractor that did the damage and then

another year until we were contacted as management at the hospital was

at a loss as to how to proceed. Compounding the problem, during the

three-year time period, there were problems with leaching plasticizers

and silicone from the degraded caulking. After consultation with us and

gaining a complete understanding of our experience and expertise, our

client contracted us to remove the stains and scratches and return the

stainless steel panels to "like new" prestine condition.

York Property Company

Solution:

Removing the stains and scratches from the damaged stainless steel

panels required our decades of weathered stainless steel refinishing

and scratched stainless steel building facade restoration experience.

The repair of the damaged facade panels posed many challanges due to

the type of damage, the number of panels damaged and the overall

surface area. The wall is comprised of 115 facade panels and 106 inner

& outer end caps with a combined total of 4750 sq. ft. As degraded

stainless steel building facade refinishing and scratched stainless

steel restoration specialists, we restoration cleaned the stainless

steel building facade cladding panels first and then regrained the

panels removing the damaging scratches with our scratched stainless

steel refinishing program. These two stainless steel remediation

programs removed the stains, repaired the uneven scratches imparting a

uniform #4 brushed finish. When the project was complete our client was

extremely pleased as the staining, scratches and silicone caulking

residue was expertly removed and the panels are now clean and shiny

with an even grain and original luster.

|

|

|

|

|

|

| Case Study 55 - Reconditioning Pitting and Rusting Stainless Steel |

|

|

|

>> View

Case Study here.

|

|

Condition:

At the Borgata Casino in Atlantic City, New Jersey new stainless steel

statues were installed in the pool / spa area. The constant temperature

of 90 degrees, chlorine, chemicals and the high humidity of the

corrosive environment had the stainless steel statues stained,

corroding, rusting and pitting in a few months. The rusting, oxidized

and pitted stainless steel metal finish was completely corroded,

unacceptable and an eyesore. The stainless steel required grinding,

stripping and resurfacing.

York Property

Company Solution:

As oxidized and rusting stainless steel contracting specialists we were

contracted to clean, repair and refinish the rust and corrosion damaged

stainless steel finish. We renewed and refurbished the stainless steel

metal finish using our exterior stainless steel reconditioning and

refinishing system. The stainless steel refinishing removed all of the

contaminants, rust, pitting, stains and oxidation. Our clear protective

coating application will stop corrosion damage, rust and pitting from

occurring on the surface of the stainless steel. |

|

|

|

|

|

Case Study 44 - Oxidized and Pitted Satin Finish Stainless Steel Refinishing

|

|

|

|

>> View

Case Study here.

|

|

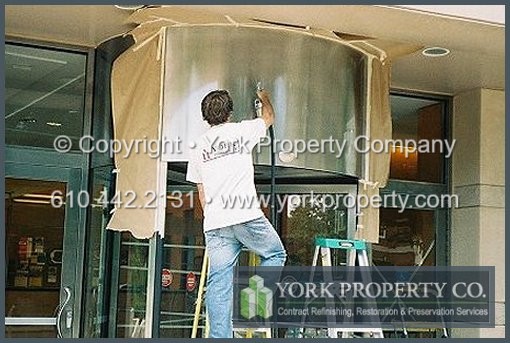

Condition:

The stainless steel clad

revolving door drum, stainless steel revolving doors and stainless

steel swing doors on all twenty-six entrances had oxidized, pitted and

started rusting. The aged, winter salt damaged, sun and UV weathered

and faded lacquer wore out and was cracking, peeling and wearing off

the stainless steel finishes. The exposed stainless steel was rusting

and pitting. The doors and door handles with human contact were

scratched and stained. On-site stainless steel refinishing was required

to remove the scratches and rust from the stainless steel.

York Property

Company Solution: The stainless steel refinishing, stainless steel

repair and stainless steel restoration was completed on the weekend

over many months. After the failed lacquer was removed we got the rust,

corrosion, oxidation, pitting and scratches off the stainless steel

satin finish. We then spray applied a fresh coat of lacquer to protect

the stainless steel from salt, rust, oxidation, pollutants, stains and

wear and tear. The stainless steel revolving doors and stainless steel

entrance doors are now clean, refurbished, restored and reconditioned. |

|

|

|

|

|

| Case Study 70 - Refinishing Corroded and

Rusting Stainless Steel Railings |

|

|

|

>> View

Case Study here.

|

|

Condition:

The architectural stainless steel railings at Johnson and Johnson in

Morris Plains, New Jersey were rusting, oxidized, weathered and

pitting. Corrosion, staining and tarnish had overtaken the stainless

steel railing finishes. A lack of stainless steel maintenance washing

allowed the stainless steel finish to wear out, get old, get salt

damaged, corrode, oxidize and rust. The original stainless steel gloss

and sheen had worn off and the stainless steel had an iron oxide brown

patina. The stainless steel needed to be renewed, polished, resurfaced

and refinished to make the stainless steel railings shine and have the

original factory stainless steel satin finish and luster.

York Property

Company Solution:

We removed the stainless steel rust, repaired the stainless steel

damage and restored the stainless steel railing finishes over a weekend

when the building was closed. To complete the stainless steel

refinishing and stainless steel restoration project we had to get the

rust off the stainless steel and remove the corrosion, patina,

scratches and stains. The stainless steel surface rust, corrosion,

pitting and discoloration required our stainless steel rust removal and

stainless steel metal refinishing systems to achieve the desired satin

stainless steel surface finish and color depth. As stainless steel

cleaning, stainless steel refinishing and stainless steel maintenance

experts the stainless steel railings are now clean, rejuvenated,

restored and protected. |

|

|

|

|

|

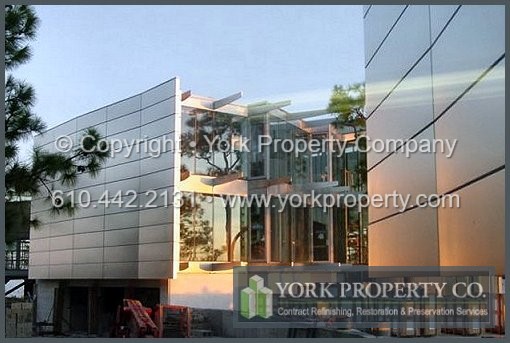

| Case Study 3 - Dirty, Stained and Oxidized Stainless Steel Cladding Restoration Cleaning |

|

|

|

>> View

Case Study here.

|

|

Condition:

The Type 316 exterior stainless steel curtain wall metal cladding

panels on this San Jose, California entertainment complex had degraded

from ten years of exposure to the sun, waterborne and airborne

contaminants and pollutants. The stainless steel cladding was dirty,

stained, oxidized, pitting, rusting and corroded. Ownership wanted the

curtain wall stainless steel cladding panels clean, repaired and

refurbished.

York Property

Company

Solution:

As stainless steel metal cladding and curtain wall metal restoration

specialists we specified the correct stainless steel restoration

cleaning methods and

materials and were contracted to restore the stainless steel clad

curtain wall to the original luster for the building's ten year

anniversary. The stainless steel panels are now clean, repaired and

protected from any further environmental damage. |

|

|

|

|

|

| Case Study 17 - Refinishing Contaminated and Rusting Stainless Steel Roof Panels |

|

|

|

>> View

Case Study here.

|

|

Condition:

The new stainless steel 24 gauge 304 2-B roof panels, stainless steel

gutters and stainless steel down spouts on this Longboat Key, Florida

oceanfront residence were contaminated, stained, oxidized and rusting.

The stainless steel was not washed prior to it being shipped to the job

site. Stainless steel manufacturing particulate and stainless steel

fabrication debris was embedded in the stainless steel finish. When the

stainless steel was exposed to humidity, salt water mist and corrosive

salt air the iron oxide on the stainless steel surface discolored and

started rusting. If the stainless steel was not cleaned immediately,

the stainless steel surface finish would pit and rust beyond repair.

York Property

Company

Solution: The manufacturer requested that we clean and

refurbish the Type 304 stainless steel roof panels, stainless steel

gutters and stainless steel down spouts. As stainless steel rust

removal, oxidized stainless steel refinishing and discolored stainless

steel restoration specialists we removed the rust, washed away the

damaging contaminants and got the corrosive stainless steel fabrication

particulate out of the stainless steel finish. The stainless steel in

now clean and rust free. The caustic and acidic materials that were

embedded in the stainless steel finish were removed and the stainless

steel is now protected from the caustic environmental elements, salt

air / salt water, waterborne and airborne pollutants and corrosive

contaminants. |

|

|

|

|

|

| Case Study 10 - Stained and Oxidized Stainless Steel Building Facade Panel Restoration |

|

|

|

>> View

Case Study here.

|

|

Condition:

The exterior stainless steel metal storefront, stainless steel window

frames and stainless steel siding panels on the Adidas, USA building

facade in Spartanburg, South Carolina were stained, rusting, oxidized and bleached from years of

exposure to damaging elements and a lack of routine maintenance

washing. The unsightly damage to the stainless steel panels required

our stainless steel metal refinishing expertise and stainless steel

rust removal program. Our client wanted the caulking and silicone

stained stainless steel repaired, clean and rust free for many years to

come.

York Property

Company

Solution: Cleaning and repairing the damaged stainless

steel panels required our years of stainless steel refinishing and

restoration experience. As oxidized stainless steel cleaning and

rusting stainless steel restoration specialists we cleaned and restored

the stainless steel building facade cladding panels with our stainless

steel restoration cleaning, rust and scratch removal systems. This made

the dirty, dull, rusting, faded and corroded building shine. The rust,

staining, pitting, corrosion and oxidation was carefully removed as to

not further damage the satin stainless steel finish on the stainless

steel building facade panels and stainless steel storefront window

frames. |

|

|

|

|

|

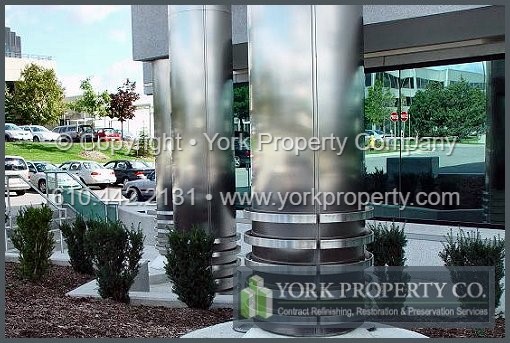

Case Study 20 - Cleaning, Repairing and Restoring Discolored Stainless Steel

|

|

|

|

>> View

Case Study here.

|

|

Condition:

The exterior polished stainless steel column covers on the ATI

Technologies Inc. building in Markham, Ontario were damaged, stained, visually displeasing

and rusting. The stainless steel clad column covers were in need of

oxidized stainless steel cleaning, stainless steel rust removal and

stained stainless steel refinishing. Without this stainless steel rust

removal program and stainless steel refinishing the exterior stainless

steel column covers would degrade further to a point beyond repair.

York Property

Company Solution:

ATI Technologies Inc. specified and chose our stainless steel metal

refinishing system as the best course of action. Over a weekend, to not

interrupt building activity, we cleaned, repaired and restored the

stainless steel column covers to the original manufacturer's

specification. Our spray applied clear protective coating will protect

and maintain the integrity of the silver gray colored stainless steel

cladding from airborne and waterborne caustic pollutants and

contaminants. |

|

|

|

|

|

| Case Study 13 - Protecting Stainless Steel from Salt Water and Corrosion |

|

|

|

>> View

Case Study here.

|

|

Condition:

The stainless steel metal siding panels on this new Pensacola, Florida

oceanfront residence will be continually exposed to the sun, humidity,

heat, salt water mist and corrosive salt air. All of these acidic,

corrosive and caustic elements are a recipe for rust, oxidation and

corrosion. In this damaging and corrosive environment the satin finish

silver colored stainless steel clad siding panels will stain, pit and

rust in a matter of months. The owners wanted a stainless steel

cleaning, washing and maintenance specification to keep the stainless

steel metal clad building facade panels from staining, pitting and

rusting.

York Property

Company

Solution: They required that the stainless steel clad

siding continually look new, clean and rust free. As stainless steel

rust removal, stainless steel cleaning and stainless steel restoration

specialists we specified the correct cleaning methods and materials to

enable the on-site maintenance staff to keep the exterior stainless

steel siding panels clean, protected, stain and rust free from the

caustic environmental elements, salt air / salt water damage,

waterborne and airborne pollutants and contaminants associated with an

oceanfront residence. |

|

|

|

|

|

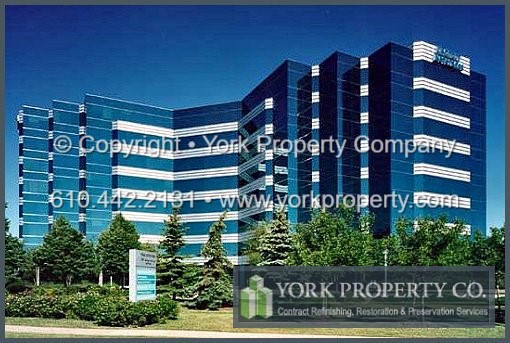

Case Study 42 - Oxidized Stainless Steel Curtain Wall Refinishing

|

|

|

|

>> View

Case Study here.

|

|

Condition: The

architectural metals

on this commercial building in Mississauga, Ontario are horizontal

anodized aluminum panels and stainless steel mullions. The anodized

aluminum was stained and severely oxidized. The stainless steel was

corroding, discolored and starting to rust as it had not been

maintained since the building was new. The anodized aluminum and

stainless steel weathering, oxidation and corrosion was caused by years

of exposure to waterborne pollutants, airborne contaminants, window

cleaning chemicals and UV exposure. Cleaning, refurbishing and

restoring the old, dirty and aged anodized aluminum and stainless steel

was required.

York Property

Company Solution: This building is the head office

of a commercial real estate development company and the condition of

the curtain wall anodized aluminum and stainless steel was

unacceptable. The oxidized anodized aluminum and the corroded stainless

steel made the building look old and visually displeasing. Ownership

specified that we clean and restore the anodized aluminum and stainless

steel panels to like new. We were able to remove the corrosion and rust

from the stainless steel and get the oxidation and discoloration off of

the anodized aluminum. Our exterior architectural metal refinishing

systems provided the results our client expected. |

|

|

"I just want to

write

you a short note and congratulate you and your staff on a job well

done! Your hard work has certainly paid off, as the stainless steel

exterior of

our Polaris Realty head office building looks as good as new."

"Your on-site personnel were courteous, clean and their attention to

safety unmatched. I will not hesitate to call on York Property

Company for future stainless steel maintenance and restoration

projects."

Construction

Manager, Central Region, Polaris Realty Limited |

|

|

| >> More

York Property Company Client

Testimonials here.

<<

|

|

|

|

|

|

|

|

York

Property Company provides

professional stainless steel

cleaning,

stainless steel refinishing, stainless steel restoration and

stainless steel maintenance services that restore the color, gloss,

luster, sheen and visual appearance. Our highly trained company

technicians clean, repair, refinish and restore stainless steel

architectural metal surface

finishes on-site.

|

|

|

|

With every stainless steel restoration project we analyze the needs

of our customers and develop a comprehensive maintenance program.

This custom stainless steel maintenance program ensures our client's

architectural stainless steel metal

finishes remain looking their best for years to come.

|

|

|

|

|

|

|

| Talk to the Experts: Contact the stainless steel refinishing experts today at 647.204.5381

for nationwide service in the United States and Canada. |

|

|

|

|

|

| United States:

Alabama, Alaska, Arizona, Arkansas, California, Colorado, Connecticut,

Delaware, Florida, Georgia, Hawaii, Idaho, Illinois, Indiana, Iowa,

Kansas, Kentucky, Louisiana, Maine, Maryland, Massachusetts, Michigan,

Minnesota, Mississippi, Missouri, Montana, Nebraska, Nevada, New

Hampshire, New Jersey, New Mexico, New York, North Carolina, North

Dakota, Ohio, Oklahoma, Oregon, Pennsylvania, Rhode Island, South

Carolina, South Dakota, Tennessee, Texas, Utah, Vermont, Virginia,

Washington, West Virginia, Wisconsin and Wyoming. |

|

| Canada: Alberta, British Columbia, Manitoba, Ontario, Quebec and Saskatchewan. |

|

|

|

|

|