|

|

|

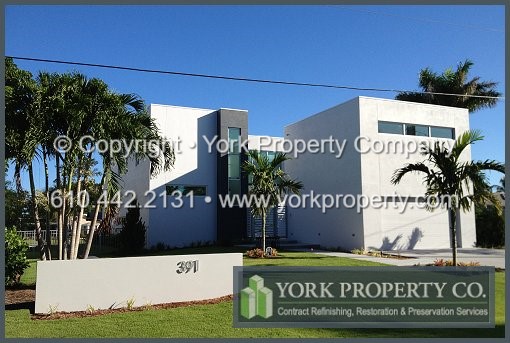

Case Study 13 - Pensacola, Florida - Oxidized and Pitted Stainless Steel Clad Panel Refinishing

|

|

|

|

|

>> View Case Study here.

|

|

Condition:

The stainless steel metal siding panels on this new Pensacola, Florida

oceanfront residence will be continually exposed to the sun, humidity,

heat, salt water mist and corrosive salt air. All of these acidic,

corrosive and caustic elements are a recipe for rust, oxidation and

corrosion. In this damaging and corrosive environment the satin finish

silver colored stainless steel clad siding panels will stain, pit and

rust in a matter of months. The owners wanted a stainless steel

cleaning, washing and maintenance specification to keep the stainless

steel metal clad building facade panels from staining, pitting and

rusting.

York Property Company

Solution: They required that the stainless steel clad

siding continually look new, clean and rust free. As stainless steel

rust removal, stainless steel cleaning and stainless steel restoration

specialists we specified the correct cleaning methods and materials to

enable the on-site maintenance staff to keep the exterior stainless

steel siding panels clean, protected, stain and rust free from the

caustic environmental elements, salt air / salt water damage,

waterborne and airborne pollutants and contaminants associated with an

oceanfront residence. |

|

|

|

|

|

| Case Study 17 - Longboat Key, Florida - Cleaning and Refinishing Rusting Stainless Steel Roof Panels |

|

|

|

>> View Case Study here.

|

|

Condition:

The new stainless steel 24 gauge 304 2-B roof panels, stainless steel

gutters and stainless steel down spouts on this Longboat Key, Florida

oceanfront residence were contaminated, stained, oxidized and rusting.

The stainless steel was not washed prior to it being shipped to the job

site. Stainless steel manufacturing particulate and stainless steel

fabrication debris was embedded in the stainless steel finish. When the

stainless steel was exposed to humidity, salt water mist and corrosive

salt air the iron oxide on the stainless steel surface discolored and

started rusting. If the stainless steel was not cleaned immediately,

the stainless steel surface finish would pit and rust beyond repair.

York Property Company

Solution: The manufacturer requested that we clean and

refurbish the Type 304 stainless steel roof panels, stainless steel

gutters and stainless steel down spouts. As stainless steel rust

removal, oxidized stainless steel refinishing and discolored stainless

steel restoration specialists we removed the rust, washed away the

damaging contaminants and got the corrosive stainless steel fabrication

particulate out of the stainless steel finish. The stainless steel in

now clean and rust free. The caustic and acidic materials that were

embedded in the stainless steel finish were removed and the stainless

steel is now protected from the caustic environmental elements, salt

air / salt water, waterborne and airborne pollutants and corrosive

contaminants. |

|

|

|

|

|

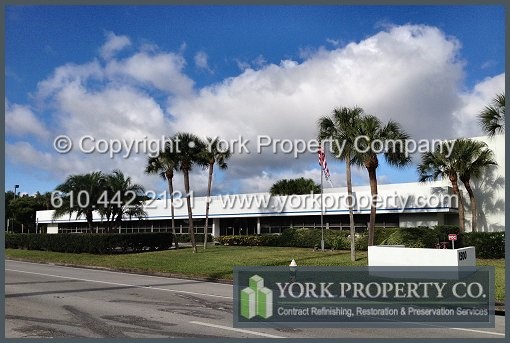

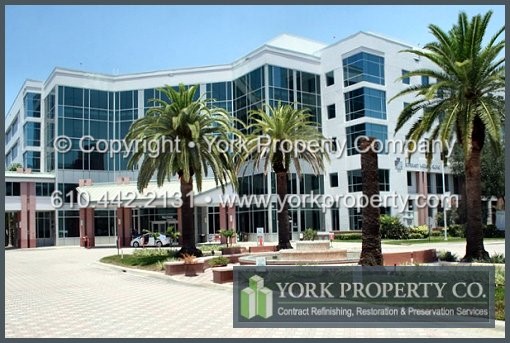

Case Study 28 - Tampa, Florida - Stained and Oxidized Clear Anodized Aluminum Building Facade Cleaning

|

|

|

|

>> View Case Study here.

|

|

Condition:

The exterior clear anodized aluminum building facade clad panels and

anodized aluminum window mullions on this commercial building in Tampa,

Florida are continually exposed to the damaging sun, heat, corrosive

humidity and UV rays. The anodized aluminum was bleached, stained,

acid etched and oxidized. To maintain the integrity of the Alucobond

anodic finish ownership requested the anodized aluminum building facade

siding panels be clean, restored and protected.

York Property Company

Solution: Our anodized aluminum Technical Consulting

Division was contracted to analyze the degraded, corroded, sun damaged

and weathered anodized aluminum building facade window mullions and

oxidized anodized aluminum clad panels. As gray colored anodized

aluminum oxidation removal, anodized aluminum pitting repair and

anodized aluminum refinishing experts we specified an on-site anodized

aluminum cleaning, refinishing and preventive maintenance program. |

|

|

|

|

|

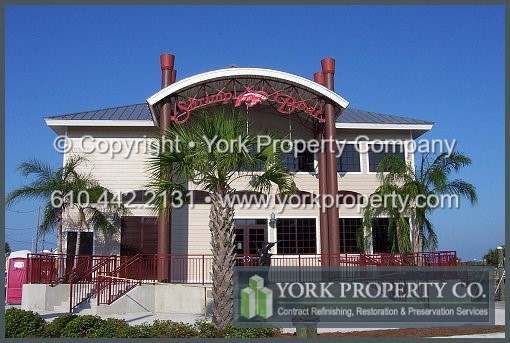

| Case Study 36 - Panama City, Florida - Cleaning and Repairing Scratched and Damaged Stainless Steel |

|

|

|

>> View Case Study here.

|

|

Condition:

The interior Type 304 stainless steel food processing equipment and

stainless steel commercial kitchen appliances at the Shrimp Boat

Restaurant in Panama City, Florida

were scratched, stained, acid etched and damaged by the stainless steel

construction cleaning contractor. Muriatic acid vapor flash rusted all

of the stainless steel surfaces. In an attempt to repair and remove the

rust and damage from the stainless steel the construction cleaning

contractor cross grained and scratched the satin finish on all of the

stainless steel surfaces.

York Property Company

Solution: As acid etched stainless steel refinishing experts, the General Contractor contracted us to repair,

restore and refinish the damaged stainless steel by removing the

scratches and rust from the finishes. We achieved this with our

stainless steel scratch removal and stainless steel rust removal

program to repair and restore the damage to the new stainless steel

surfaces. We removed the scratches, cleaned, repaired, reconditioned

and refinished the damaged stainless steel kitchen appliances and food processing equipment as if they had not been scratched

or damaged. |

|

|

|

|

|

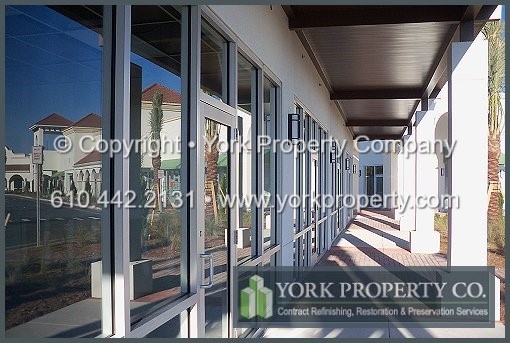

Case Study 38 - Ft. Myers, Florida - Damaged Anodized Aluminum Construction Cleaning and Repair

|

|

|

|

>> View Case Study here.

|

|

Condition:

The new Class I clear anodized aluminum storefront window frames and

anodized aluminum doors and frames on this Ft. Myers, Florida strip

mall were acid etched. The factory finished Kawneer anodized aluminum

anodic surface finish got damaged, scratched, blemished and stained

whitish gray with lime contaminated debris, acidic water and stucco

overspray. Concrete, stucco and mortar residue had splashed onto the

unprotected anodized aluminum surfaces. The anodized aluminum new

construction project was compromised by the concrete, stucco and lime

residue, white splatter, scarring, acid burns and anodized aluminum

surface imperfections.

York Property Company

Solution: The General Contractor retained us as an acid

etched anodized aluminum construction cleaning expert to clean, repair

and restore the chemical stained and acid damaged anodized aluminum

storefront window frames and scratched anodized aluminum door frames.

The architect specified that we repair the acid etching damage and

return the anodized aluminum to the original condition. We achieved

this request using our anodized aluminum concrete and mortar removal

construction cleaning restoration system. The natural color anodized

aluminum surfaces are now clean, repaired, refurbished and protected

from further damage. |

|

|

|

|

|

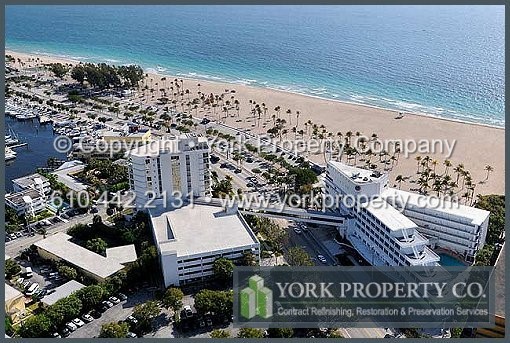

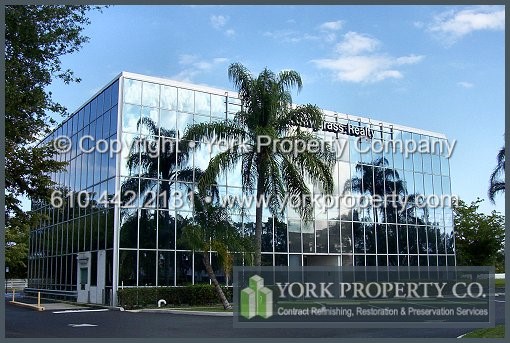

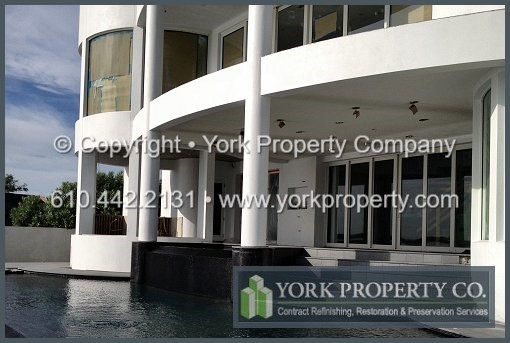

| Case Study 39 - Fort Lauderdale, Florida - Refinishing Salt Water Oxidized Anodized Aluminum Window Frames |

|

|

|

>> View Case Study here.

|

|

Condition:

The oxidized anodized aluminum window frames, bleached anodized aluminum sliding doors and

sun faded anodized aluminum balcony railings on this Fort Lauderdale, Florida

oceanfront hotel are continually exposed to the sun, UV rays,

humidity, heat, salt water mist and corrosive salt air. In this

damaging and caustic environment the clear natural colored anodized

aluminum metal finishes had weathered, oxidized, pitted and stained.

The original gloss and silver color of the anodized aluminum anodic

finish had faded, bleached and was damaged by salt in the environment.

The new hotel owners saw the results of not washing, caring for or

maintaining the anodized aluminum window mullions and frames, anodized

aluminum sliding glass doors and anodized aluminum railings.

York Property Company Solution:

The new owners required the anodized aluminum continually look new and

clean and not have any oxidation, stains or salt residue contamination.

As anodized aluminum oxidation removal, anodized aluminum pitting and

corrosion removal and anodized aluminum refinishing specialists we

specified the correct cleaning methods and renovation materials. This

anodized aluminum restoration specification enabled the stucco painting

contractor to refurbish the anodized aluminum surface finishes while

the access equipment was on-site. The spray applied lacquer now

protects the anodized aluminum window mullions from salt water damage,

salt air damage, corrosive pollutants, airborne contaminants and salt

water mist associated with an oceanfront hotel.

|

|

|

|

|

|

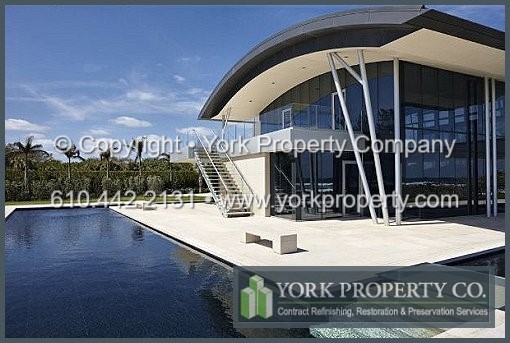

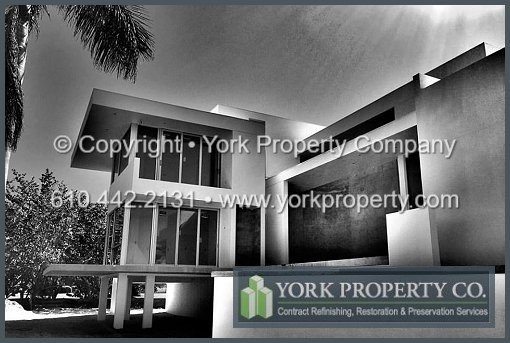

Case Study 58 - Jupiter Island, Florida - Rusting Stainless Steel Window Frame Restoration

|

|

|

|

>> View Case Study here.

|

|

Condition:

The stainless steel window frames and stainless steel doors on this new

Jupiter Island, Florida oceanfront residence are continually exposed to

the sun, humidity, heat, damaging salt water mist and corrosive salt

air. All of these acidic, corrosive and caustic elements are a recipe

for rust, oxidation and corrosion if left on the surface of the

stainless steel. In this damaging and corrosive environment the

stainless steel finish will stain, oxidize, tarnish, pit and rust in a

matter of months. The owners wanted a stainless steel cleaning,

stainless steel washing and stainless steel maintenance specification

to keep the stainless steel window frames and stainless steel doors

from staining, pitting and rusting.

York Property Company Solution:

They required that the stainless steel clad finishes continually look

new, clean and rust free. As stainless steel rust removal, stainless

steel cleaning and stainless steel restoration specialists we specified

the correct cleaning methods and materials to enable the on-site

maintenance staff to keep the exterior stainless steel window frames

and stainless steel doors clean, protected, stain and rust free from

the caustic environmental elements, salt air, corrosive waterborne and

abrasive airborne pollutants and contaminants associated with an

oceanfront residence. |

|

|

|

|

|

| Case Study 62 - Ft. Myers, Florida - Repairing Acid Etched Anodized Aluminum Window Frames |

|

|

|

>> View Case Study here.

|

|

Condition:

The new clear anodized aluminum factory finish was stained and etched

during the construction of this Ft. Myers, Florida custom home. During construction acidic concrete slurry, mortar and

corrosive cement splashed on the anodized aluminum window frames and

anodized aluminum doors. The silver colored anodized finish was acid

etched, corroded, scratched and oxidized. The G.C. requested that we

get the concrete, cement and mortar overspray stains off and get the

acid etching out of the anodized aluminum surfaces. As acid burned

anodized aluminum cleaning and chemically etched anodized aluminum

refinishing experts, our client had confidence we could recondition,

refinish and restore the damaged anodized aluminum surface finishes.

York Property Company Solution:

To clean, repair, renew and protect the damaged anodized aluminum

surfaces we refurbished the anodized aluminum with our acid etched

anodized aluminum restoration cleaning and oxidized anodized aluminum

reconditioning system. We had to remove the concrete, cement and mortar

overspray, splatter and debris while repairing and refinishing the

anodized aluminum without causing any more damage to the thin anodized

anodic finish. Although the anodized aluminum building facade window

mullions and doors were seriously damaged, our anodized aluminum

construction cleaning, restoration and rejuvenating program allowed us

to clean, repair, refurbish and restore the acid etched and oxidized

anodized aluminum to "like new". The anodized aluminum is protected

from further corrosion, oxidation and pitting. |

|

|

|

|

|

Case Study 63 - Clearwater, Florida - Stripping Faded Paint from Bronze Anodized Aluminum Window Frames

|

|

|

|

>> View Case Study here.

|

|

Condition:

The commercial bronze anodized aluminum window frames on this industrial

building in Clearwater, Florida were painted after they were installed on

the building. Over time the brown paint coating on the anodized aluminum window

frames got chalky and the pigment faded. The old weathered paint had to be

removed. The new owner of the building wanted the anodized aluminum window frames to be

restored to the original luster of new brown colored anodized aluminum. If the anodized aluminum was not

coated once it was clean and refurbished the anodized aluminum and

anodic layer would bleach, stain, acid etch and oxidize. To maintain

the integrity of the brown colored bronze anodic finish ownership

requested the anodized aluminum storefront window frames be coated

and protected with the York Property Company anodized aluminum clear

protective coating.

York Property Company Solution:

To refurbish and recondition the weathered and faded anodized aluminum window frames we had to chemically strip the paint

off the anodized aluminum finish without damaging the brown anodic

layer. Removing the paint was time consuming and required our skill,

expertise and experience as commercial anodized aluminum window frame

restoration contracting specialists. If the window frames were

bleached, burned, acid etched or scratched the anodized

aluminum would have to be painted again. The anodized aluminum

reconditioning program got the paint off of the anodized aluminum

window frames safely and refurbished the anodized aluminum dark brown

color and finish. The anodized aluminum protective coating enhanced the

reflective sheen and gloss while protecting the anodized aluminum from

the sun, mineral deposits, calcium stains and caustic airborne

contaminants.

|

|

|

|

|

|

| Case Study 64 - Alachua, Florida - Removing Stucco Overspray from Anodized Aluminum Window Frames |

|

|

|

>> View Case Study here.

|

|

Condition:

This new commercial building in Alachua, Florida had acid and

chemical burned anodized aluminum storefront window frames and stucco

contaminated anodized aluminum capped curtain wall window mullions. The

clear anodized aluminum extruded finishes were damaged, oxidized, acid

etched and stained by stucco overspray during the stucco application.

The anodized aluminum whitish beige stucco residue, construction

debris, oxidation damage, discoloration and staining had to be removed

from the anodized aluminum window frames.

York Property Company Solution:

The architect specified our firm as construction damaged anodized

aluminum cleaning and refinishing experts. The General Contractor

contracted us to use our anodized aluminum stucco removal expertise to

remove the stucco overspray, residue, particles and debris from the

stained anodized aluminum window frames and mullions. We field applied

our anodized aluminum stucco removal and construction cleaning program

to restore the new building facade anodized aluminum window frame

sections. Upon completion, the anodized aluminum looked new, clean and

free of any oxidation, acid etching or stucco damage. |

|

|

|

|

|

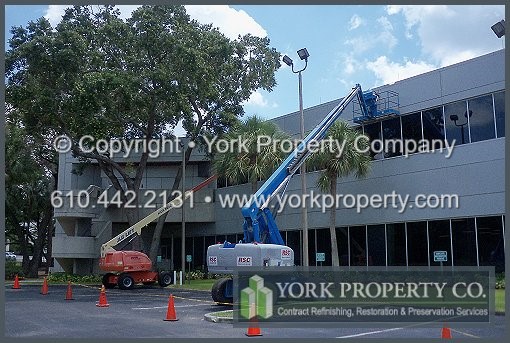

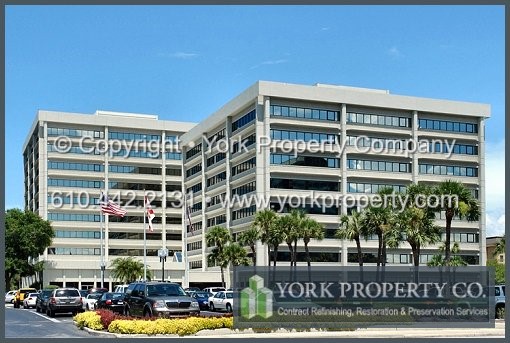

Case Study 66 - Tampa, Florida - Stained and Oxidized Anodized Aluminum Building Facade Panel Restoration

|

|

|

|

>> View Case Study here. |

|

Condition:

The exterior oxidized clear anodized aluminum building facade panels

and stained anodized aluminum window frames on this owner occupied ADP,

Inc. commercial office building in Tampa, Florida were faded,

weathered, bleach, sun and UV damaged. As well, the discolored ground

floor anodized aluminum panels were stained with calcium, hard water

stains and mineral deposits from the sprinkler system. The exterior

natural colored anodized aluminum was not clean and the owners required

the anodized aluminum siding panels and extrusions be refinished and

restored. The oxidized anodized aluminum refinishing project would

renew the anodized aluminum finishes to the original factory anodized

aluminum gloss, color and sheen.

York Property Company

Solution: Our anodized aluminum Technical Consulting Division

was contracted to analyze the faded, sun damaged and stained silver

grey anodized aluminum clad siding panels and bleached anodized

aluminum window mullions. With an analysis of the damaged anodized

aluminum finishes a long-term anodized aluminum cleaning, washing and

maintenance program was implemented to clean, refurbish, preserve and

protect the oxidized anodized aluminum clad siding and mineral stained

anodized aluminum window frames. When the anodized aluminum was

restored by our field technicians the anodized aluminum building

extrusions looked as new as the original date of installation.

|

|

|

|

|

|

| Case Study 73 - Miami, Florida - Anodized Aluminum Window Frame Scratch Removal and Removing Dry Stucco

|

|

|

|

>> View Case Study here. |

|

Condition:

This new Miami, Florida commercial strip plaza had construction damaged

clear anodized aluminum storefront window mullions, scratched anodized

aluminum doors and stained anodized aluminum window frames. During

construction, the stucco contractor scratched and dented the anodized

aluminum when they were removing stucco overspray. When they tried to

get the stucco off of the anodized aluminum window frames they

scratched the anodic aluminum surface finish. The anodized aluminum new

construction project was compromised by the corrosive oxidation,

scratches, acid etching and chemical stains.

York Property Company Solution:

The General Contractor contracted us to clean, repair and restore the

damaged and scratched natural colored anodized aluminum window frames.

We removed the scratches and whitish gray stains on the new anodized

aluminum storefront window frame sections as if they had not been

scratched or damaged. The anodized aluminum looked new and clean when

the oxidized anodized aluminum construction cleaning and anodized

aluminum scratch remover program was complete.

|

|

|

|

|

|

| Case Study 74 - Sarasota, Florida - Exterior Oxidized Anodized Aluminum Window Frame Cleaning and Refinishing

|

|

|

|

>> View Case Study here |

|

Condition: The anodized aluminum

building facade window frames on this commercial building in Sarasota,

Florida were faded, pitted, oxidized, bleached and stained. The

anodized aluminum window frames looked old, dirty, aged and faded as

they had never been cleaned, washed or maintained since the building

was new. To protect the anodized aluminum from further damage Property

Management wanted the anodized aluminum cleaned, repaired and restored.

York Property Company Solution:

The exterior anodized aluminum building facade window frames were

refurbished with our exterior anodized aluminum cleaning and

refinishing system. The anodized aluminum was restoration cleaned and

the anodized aluminum window frames were coated with the specified

clear protective coating. With the anodized aluminum surfaces now

clean, the coating will preserve and protect the anodic layer from

airborne and waterborne contaminants, sun and u.v exposure and all

around general weathering.

|

|

|

|

|

|

| Case Study 86 - St. Petersburg, Florida - Restoring Acid Etched Anodized Aluminum Window Frames

|

|

|

|

>> View Case Study here |

|

Condition:

The new exterior commercial grade Class I clear anodized aluminum

window frames and sills on this Hospital in St. Petersburg, Florida

were damaged, discolored, stained and acid etched by the construction

cleaning contractor acid cleaning the colored cement based stucco above

the anodized aluminum window frames. The acidic restoration cleaning

chemical flash etched, acid burned and oxidized all of the clear

anodized aluminum window frames and they were no longer clean or in

original condition. The General Contractor demanded a solution to clean

and refurbish the stained and oxidized clear anodized aluminum window

frames to the original color, sheen and condition.

York Property Company Solution:

Our anodized aluminum window frame acid etching and anodized aluminum

window frame oxidation removal program allowed our on-site technicians

to remove the acid etching stains and chemical burns from the anodized

aluminum surface finish of the clear anodized aluminum window frames.

The commercial anodized aluminum building facade window frames were

cleaned, repaired, preserved and protected from any further damage from

the caustic environmental elements and are now as good as new for many

years to come.

|

|

|

|

|

|

| Case Study 91 - Longboat Key, Florida - Repairing Concrete Stained Anodized Aluminum Window Frames

|

|

|

|

>> View Case Study here |

|

Condition:

The new clear anodized aluminum factory finish was stained and etched

during the construction of this Longboat Key, Florida custom home. During construction acidic concrete slurry, mortar and

corrosive cement splashed on the anodized aluminum window frames and

anodized aluminum doors. The silver colored anodized finish was acid

etched, corroded, scratched and oxidized. The G.C. requested that we

get the concrete, cement and mortar overspray stains off and get the

acid etching out of the anodized aluminum surfaces. As acid burned

anodized aluminum cleaning and chemically etched anodized aluminum

refinishing experts, our client had confidence we could recondition,

refinish and restore the damaged anodized aluminum surface finishes.

York Property Company Solution:

To clean, repair, renew and protect the damaged anodized aluminum

surfaces we refurbished the anodized aluminum with our acid etched

anodized aluminum restoration cleaning and oxidized anodized aluminum

reconditioning system. We had to remove the concrete, cement and mortar

overspray, splatter and debris while repairing and refinishing the

anodized aluminum without causing any more damage to the thin anodized

anodic finish. Although the anodized aluminum building facade window

mullions and doors were seriously damaged, our anodized aluminum

construction cleaning, restoration and rejuvenating program allowed us

to clean, repair, refurbish and restore the acid etched and oxidized

anodized aluminum to "like new". The anodized aluminum is protected

from further corrosion, oxidation and pitting.

|

|

|

|

|

|

| Case Study 92 - Tampa, Florida - Removing Peeling Paint from Bronze Anodized Aluminum Window Frames

|

|

|

|

>> View Case Study here |

|

Condition: The Kawneer Class I

exterior bronze anodized aluminum window frames on these commercial

buildings in Tampa, Florida were painted after they were installed on

the building. The brown paint coating on the anodized aluminum window

frames were peeling and the old, brittle, flaking paint had to be

removed. The owners wanted the anodized aluminum window frames to be

restored to the original luster of new brown colored anodized aluminum

window frames, sills and flashing. If the anodized aluminum was not

coated once it was clean and refurbished the anodized aluminum and

anodic layer would bleach, stain, acid etch and oxidize. To maintain

the integrity of the brown colored bronze anodic finish ownership

requested the anodized aluminum building facade window frames be coated

and protected with the York Property Company anodized aluminum clear

protective coating.

York Property Company Solution:

To refurbish and recondition the old, faded and contaminated exterior

anodized aluminum window frames we had to chemically strip the paint

off the anodized aluminum finish without damaging the brown anodic

layer. Removing the paint was time consuming and required our skill,

expertise and experience as commercial anodized aluminum window frame

restoration contracting specialists. If the window frames were

bleached, burned, oxidized, acid etched or scratched the anodized

aluminum would have to be painted again. The anodized aluminum

reconditioning program got the paint off of the anodized aluminum

window frames safely and refurbished the anodized aluminum dark brown

color and finish. The anodized aluminum protective coating enhanced the

reflective sheen and gloss while protecting the anodized aluminum from

the sun, mineral deposits, calcium stains and caustic airborne

contaminants.

|

|

|

|

|

|

| Case Study 96 - Clearwater Beach, Florida - Field Painting New Residential Painted Aluminum Window Frames

|

|

|

|

>> View Case Study here |

|

Condition:

The factory applied white paint finish on the new exterior painted

aluminum window frames had started cracking and peeling due to interior

paint being applied at the factory vs. exterior paint as specified. The

paint finish was prematurely fading, flaking off and peeling. The G.C.

required that this situation be remedied immediately as the luxury

ocean front residence in Clearwater Beach, Florida was still under

construction.

York Property Company Solution:

As painted aluminum window frame restoration contracting specialists we

were contracted to mobilize on-site and chemically strip the failing

paint and abrade the window frames down to the mill finish aluminum. We

could not paint over the failing paint as the bond line adhesion was

compromised. After the stripping and surface cleaning was complete we

primed and then spray applied the originally specified paint to all

exterior painted aluminum window frame surfaces.

|

|

|

|

|

|

| Case Study 97 - Rockledge, Florida - Cleaning Stucco Stains on New Bronze Anodized Aluminum Window Frames

|

|

|

|

>> View Case Study here |

|

Condition:

The new Class I bronze anodized aluminum storefront window frames and

anodized aluminum doors on this large construction project in

Rockledge, Florida were oxidized and acid etched during construction.

The factory finished anodized aluminum surface finish was acid burned,

blemished and stained whitish gray with lime contaminated debris,

acidic water and stucco overspray. The stucco contractor failed to tape

the window frame perimeter edge correctly allowing acidic stucco to

leech onto the fragile bronze anodic layer. The anodized aluminum new

construction project was compromised by the stucco and lime residue,

white stucco splatter, scarring and acid burns.

York Property Company

Solution:

The General Contractor contracted us to clean,

repair and restore the damaged, oxidized and acid etched bronze

anodized aluminum

window frames. We removed the acid burns and white colored stains on

the

new anodized aluminum window frame sections as if they had not been

acid etched, stained or damaged. The architect specified that we repair

the acid etching damage and return the anodized aluminum to the

original condition. The bronze anodized aluminum looked new and clean

when the anodized aluminum construction cleaning and anodized aluminum

stucco and acid etching removal program was complete.

|

|

|

|

|

|

|

|

York

Property Company

provides professional oxidized anodized

aluminum window frame cleaning,

faded anodized aluminum clad panel refinishing, old anodized

aluminum curtain wall restoration and discolored anodized aluminum

building facade refinishing services that restore the color, gloss,

luster, sheen and visual appearance. Our highly trained company

technicians clean, repair, refinish and restore anodized aluminum,

painted aluminum and stainless steel finishes on-site in Florida.

Contact the architectural metal restoration specialists today in Florida at 647.204.5381

and request an analysis of your building's scratched, marred, scuffed

and blemished architectural metal finishes. Our industry-leading,

skilled, experienced and knowledgeable technical consultants will

specify a customized long-lasting and cost-effective

stained anodized aluminum building facade panel cleaning, rusting

stainless steel surface reconditioning and faded painted aluminum

curtain wall panel refinishing specification that will beautify,

improve, maintain, restore and protect all your architectural metal

finishes. |

|

|

|

|

|

|

| Florida:

Bal Harbour, Boca Raton, Bradenton, Cape Canaveral, Cape Coral, Clearwater, Coral

Gables, Daytona, Fort Lauderdale, Fort Myers, Gainesville, Hialeah, Homestead,

Jacksonville, Jupiter, Key Biscayne, Key West, Longboat Key, Marco Island, Miami, Miami Beach,

Naples, Ocala, Okeechobee, Orlando, Palm Beach, Panama City,

Pembroke Pines, Pensacola, Pompano Beach, St. Augustine,

St. Petersburg, Sarasota, Tallahassee, Tampa & Venice |

|

|

|

|

|