|

|

|

York Property Company

provides high quality oxidized anodized aluminum building restoration,

rusting stainless steel building restoration, dirty anodized aluminum

building restoration and discolored stainless steel building

restoration solutions.

Our highly trained company technicians clean,

repair, refinish and restore oxidized anodized aluminum, color faded painted aluminum and

rusting stainless steel building facade finishes on-site.

Talk to the Experts:

Contact the metal building restoration experts today at 647.204.5381

and request a comprehensive analysis of your building's pitted, stained, faded and

oxidized architectural building facade metal finishes.

Schedule a Site Visit: Our industry-leading, skilled, experienced and knowledgeable technical consultants will specify a customized long-lasting and cost-effective weathered anodized aluminum building restoration, faded painted

aluminum building restoration and stained anodized aluminum building

restoration specification that will beautify, recondition, improve, restore and protect all your architectural metal finishes. |

|

|

|

|

|

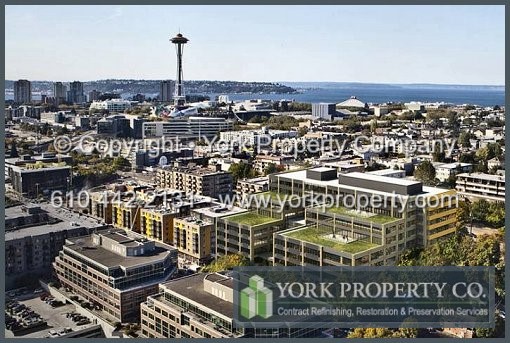

Case Study 81 -

Scratched Anodized Aluminum Building Restoration

|

|

|

|

>>

View Case Study here. |

|

|

Condition:

The new interior clear anodized aluminum window frames were scuffed,

scratched and dented during the installation and construction of

Facebook's new offices in Seattle, Washington. As well, steel shavings

left iron oxide rust deposits in various locations on the anodized

aluminum window frames further compounding the overall damage that had

to be remedied. The G.C. requested that we remove the rust, repair the

scratches and cap the dents with Class I anodized aluminum break metal.

As scratched anodized aluminum refurbishing and dented anodized

aluminum restoration contracting experts, our client had confidence we

could clean, refinish and repair the damaged anodized aluminum window

frames.

York Property Company Solution:

To clean off the rust and remove the scratches and stains from the

anodized aluminum window sills and frames we used our anodized aluminum

restoration, refinishing and reconditioning system. We had to remove

the rust and get the oxidation and particulate off while cleaning and

refinishing the anodized aluminum without causing any more damage to

the anodized aluminum window frame finishes. Although the interior

anodized aluminum window mullions, sills and window frames were

seriously damaged, our scratched anodized aluminum construction

cleaning, restoration and refurbishing program allowed us to clean,

repair and restore the scratched, scuffed, marked and dented anodized

aluminum to "like new". |

|

|

|

|

|

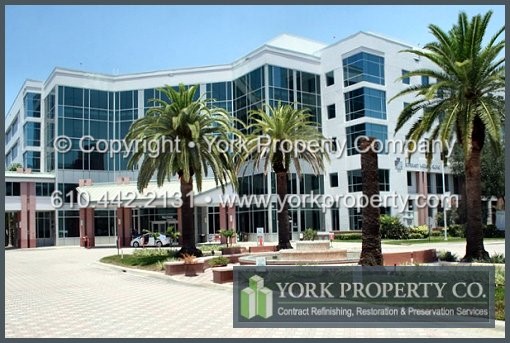

| Case Study 86 -

Acid Etched Anodized Aluminum

Building Restoration |

|

|

|

>>

View Case Study here.

|

|

Condition:

The new exterior commercial grade Class I clear anodized aluminum

window frames and sills on this Hospital in St. Petersburg, Florida

were damaged, discolored, stained and acid etched by the construction

cleaning contractor acid cleaning the colored cement based stucco above

the anodized aluminum window frames. The acidic restoration cleaning

chemical flash etched, acid burned and oxidized all of the clear

anodized aluminum window frames and they were no longer clean or in

original condition. The General Contractor demanded a solution to clean

and refurbish the stained and oxidized clear anodized aluminum window

frames to the original color, sheen and condition.

York Property Company Solution:

Our anodized aluminum window frame acid etching and anodized aluminum

window frame oxidation removal program allowed our on-site technicians

to remove the acid etching stains and chemical burns from the anodized

aluminum surface finish of the clear anodized aluminum window frames.

The commercial anodized aluminum building facade window frames were

cleaned, repaired, preserved and protected from any further damage from

the caustic environmental elements and are now as good as new for many

years to come. |

|

|

|

|

|

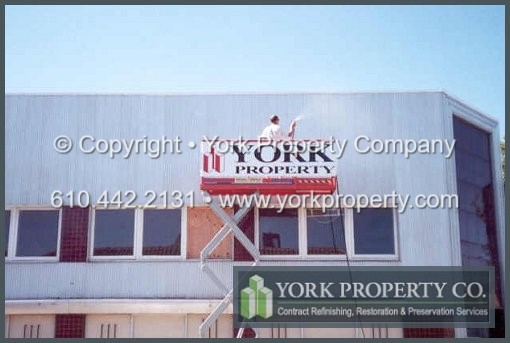

| Case Study 88 - Oxidized Corrugated Aluminum Building Facade Panel Restoration |

|

|

|

>>

View Case Study here |

|

Condition:

The corrugated aluminum clad siding on this historical retail building

in San Mateo, California was stained, weathered and severely oxidized

from decades of exposure to the California sun. The aluminum siding

panels were acid etched, bleached and the finish was uneven. The

aluminum silver color was faded and satin sheen was dull. The building

owner required our expertise to clean repair, renew and restore the

aluminum building siding panels.

York Property Company Solution:

Working with the owner and an architect our Technical Consulting

Division specified an aluminum siding cleaning, refinishing,

maintenance and preservation solution. Ownership wanted the aluminum

siding refurbished and the factory finish gloss and luster returned to

the aluminum panels. We cleaned, repaired, resurfaced and restored the

oxidized aluminum siding and spray applied a lacquer coating to protect

the aluminum siding from corrosion, salt air, UV damage, pollutants,

weathering and contaminants. |

|

|

|

|

|

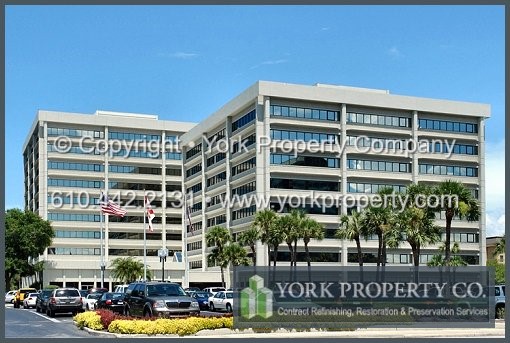

| Case Study 92 -

Damaged Painted Aluminum Building Refinishing and Restoration |

|

|

|

>>

View Case Study here.

|

|

Condition: The Kawneer Class I

exterior bronze anodized aluminum window frames on these commercial

buildings in Tampa, Florida were painted after they were installed on

the building. The brown paint coating on the anodized aluminum window

frames were peeling and the old, brittle, flaking paint had to be

removed. The owners wanted the anodized aluminum window frames to be

restored to the original luster of new brown colored anodized aluminum

window frames, sills and flashing. If the anodized aluminum was not

coated once it was clean and refurbished the anodized aluminum and

anodic layer would bleach, stain, acid etch and oxidize. To maintain

the integrity of the brown colored bronze anodic finish ownership

requested the anodized aluminum building facade window frames be coated

and protected with the York Property Company anodized aluminum clear

protective coating.

York Property Company Solution:

To refurbish and recondition the old, faded and contaminated exterior

anodized aluminum window frames we had to chemically strip the paint

off the anodized aluminum finish without damaging the brown anodic

layer. Removing the paint was time consuming and required our skill,

expertise and experience as commercial anodized aluminum window frame

restoration contracting specialists. If the window frames were

bleached, burned, oxidized, acid etched or scratched the anodized

aluminum would have to be painted again. The anodized aluminum

reconditioning program got the paint off of the anodized aluminum

window frames safely and refurbished the anodized aluminum dark brown

color and finish. The anodized aluminum protective coating enhanced the

reflective sheen and gloss while protecting the anodized aluminum from

the sun, mineral deposits, calcium stains and caustic airborne

contaminants. |

|

|

|

|

|

Case Study 8 -

Degraded Bronze Anodized Aluminum Building Restoration

|

|

|

|

>>

View Case Study here. |

|

Condition:

A lack of remedial maintenance washing of the exterior dark bronze

anodized aluminum clad panels at Kimberly-Clark's office campus in Neenah, Wisconsin caused the

brown anodized aluminum panels to bleach, stain, acid

etch and oxidize. As the anodized aluminum panels were never

washed or polished they aged from exposure to airborne and waterborne

contaminants, pollutants, acid rain, sun damage and UV exposure. The

lack of maintenance washing contributed to the corrosion and stains on

the bronze anodized aluminum metal finishes. Ownership had not followed

the original anodized aluminum manufacturers washing and preventive

maintenance schedule since the anodized aluminum panels were new.

York Property Company Solution:

Jones Lang LaSalle, building management, realized that anodized aluminum panel

washing and maintenance was vital to maintain the thirty-three year old

bronze anodized aluminum anodic finish over the long-term. We were

contacted to analyze the degraded, stained, corroded, weathered and

oxidized exterior bronze anodized aluminum cladding panels. With the findings of our analysis and

specification we were contracted to clean and refinish the contaminated bronze anodized aluminum finishes. Our anodized

aluminum cleaning and refinishing system cleaned, refurbished and

protected the anodized aluminum panels, restoring the

original natural brown color, gloss and sheen to the bronze anodized

finish. |

|

|

|

|

|

| Case Study 24 -

Acid Etched Anodized Aluminum Building Restoration |

|

|

|

>>

View Case Study here.

|

|

Condition:

The exterior mold stained clear anodized aluminum metal siding panels,

mildew discolored anodized aluminum window frames and dirty anodized

aluminum window mullions on this commercial building in Boise, Idaho

were stained, faded, dull and oxidized. The anodized aluminum metal

clad siding panels were mold and mildew stained in the areas where the

siding was shaded by the trees. The owner was selling the anodized

aluminum clad commercial office building and required that the

oxidation, mold and mildew stains be removed and that the natural

silver colored anodized aluminum siding panels be clean.

York Property Company Solution:

The damaged and stained anodized aluminum metal siding, anodized

aluminum window frames and anodized aluminum mullions on this building

facade were cleaned, repaired and refurbished with our anodized

aluminum mold and mildew stain removal program. Using this program

removed the stains from the anodized aluminum and allowed us to apply

our anodized aluminum clear protective coating to protect the natural

silver anodized aluminum siding color from caustic and damaging mold,

mildew, pollutants and contaminants. |

|

|

|

|

|

Case Study 25 -

Construction Damaged Anodized Aluminum Building Restoration

|

|

|

|

>>

View Case Study here. |

|

Condition:

The interior clear anodized aluminum window frames and anodized

aluminum mullions on this new construction project in Washington, DC

were damaged and stained during construction. Iron oxide metal shavings

and grinding dust had covered all of the anodized aluminum window frame

surface finishes. The metal shavings impregnated the anodized aluminum

surface and started rusting. The rust within the anodized aluminum

metal finish could not be removed with traditional anodized aluminum

construction cleaning.

York Property Company

Solution: The General Contractor contracted us as anodized

aluminum refinishing experts to clean and recondition the rust damaged

anodized aluminum window frames. We had to return the clear anodized

aluminum clad window mullions to the original silver color and

condition without damaging the anodized anodic layer protecting the

aluminum substrate. This was achieved using our oxidized anodized

aluminum construction cleaning and anodized aluminum rust removal

system. The anodized aluminum window frames are now clean, repaired and

free of damage. |

|

|

|

|

|

| Case Study 30 -

Construction Cleaning and Building Restoration |

|

|

|

>>

View Case Study here.

|

|

Condition:

The new clear anodized aluminum factory finish was stained and etched

during the renovation and restoration of this Washington, DC landmark

building. During construction acidic concrete slurry, mortar and

corrosive cement splashed on the anodized aluminum window frames and

anodized aluminum doors. The silver colored anodized finish was acid

etched, corroded, scratched and oxidized. The G.C. requested that we

get the concrete, cement and mortar overspray stains off and get the

acid etching out of the anodized aluminum surfaces. As acid burned

anodized aluminum cleaning and chemically etched anodized aluminum

refinishing experts, our client had confidence we could recondition,

refinish and restore the damaged anodized aluminum surface finishes.

York Property Company Solution:

To clean, repair, renew and protect the damaged anodized aluminum

surfaces we refurbished the anodized aluminum with our acid etched

anodized aluminum restoration cleaning and oxidized anodized aluminum

reconditioning system. We had to remove the concrete, cement and mortar

overspray, splatter and debris while repairing and refinishing the

anodized aluminum without causing any more damage to the thin anodized

anodic finish. Although the anodized aluminum building facade window

mullions and doors were seriously damaged, our anodized aluminum

construction cleaning, restoration and rejuvenating program allowed us

to clean, repair, refurbish and restore the acid etched and oxidized

anodized aluminum to "like new". The anodized aluminum is protected

from further corrosion, oxidation and pitting. |

|

|

|

|

|

Case Study 36 -

Muriatic Acid Vapor Stainless Steel Building Restoration

|

|

|

|

>>

View Case Study here. |

|

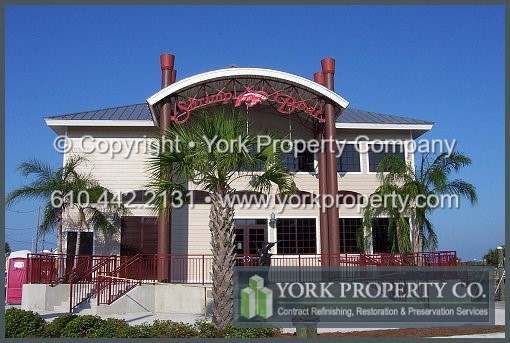

Condition:

The interior Type 304 stainless steel food processing equipment and stainless steel commercial kitchen appliances at the Shrimp Boat Restaurant in Panama City, Florida

were scratched, stained, acid etched and damaged by the stainless steel

construction cleaning contractor. Muriatic acid vapor flash rusted all

of the stainless steel surfaces. In an attempt to repair and remove the

rust and damage from the stainless steel the construction cleaning

contractor cross grained and scratched the satin finish on all of the

stainless steel surfaces.

York Property Company

Solution: As acid etched stainless steel refinishing experts, the General Contractor contracted us to repair,

restore and refinish the damaged stainless steel by removing the

scratches and rust from the finishes. We achieved this with our

stainless steel scratch removal and stainless steel rust removal

program to repair and restore the damage to the new stainless steel

surfaces. We removed the scratches, cleaned, repaired, reconditioned

and refinished the damaged stainless steel kitchen appliances and food processing equipment as if they had not been scratched

or damaged. |

|

|

|

|

|

| Case Study 71 -

Water Damaged Anodized Aluminum Building Restoration Cleaning |

|

|

|

>>

View Case Study here.

|

|

Condition:

The clear anodized aluminum curtain wall window frames, balcony doors

and mullions on this Houston, Texas luxury condominium were stained,

discolored and water damaged during construction. The anodized aluminum

metal curtain wall system leaked allowing rain water to leach through

the concrete floor slab depositing lime, whitish calcium and gray

acidic mineral deposits on the anodized aluminum window frames as the

rain water dried on the interior and exterior metal finishes. The

oxidized anodized aluminum new construction window frames, sliding

doors and siding clad panels had to be cleaned, repaired, refinished

and restored to like new condition.

York Property Company

Solution: The G.C. required us to remove the hard water

stains, white calcium deposits, waterborne contaminants and the acidic

mineral deposit residue from the anodized aluminum. These corrosive

deposits had stained, acid etched and oxidized the anodized aluminum

metal surfaces. On-site we got the dried on hard water stains and

deposits off the anodized aluminum finish. We refurbished,

reconditioned and restored the water damaged anodized aluminum curtain

wall window frame and mullion extrusions as if they had not been

stained, blemished or damaged. The clear anodized aluminum window

frames looked renewed and clean when the anodized aluminum repair,

renovation and restoration was complete. |

|

|

|

|

|

|

|

York

Property Company

provides professional oxidized anodized aluminum building restoration,

rusting stainless steel building restoration, dirty anodized aluminum

building restoration and discolored stainless steel building

restoration solutions that restore the color, gloss, luster, sheen and visual appearance.

Our highly trained company technicians clean,

repair, refinish and restore anodized aluminum, painted aluminum and

stainless steel building facade finishes on-site.

Consult with an Expert:

Contact the architectural metal building restoration professionals today at 647.204.5381

and request a comprehensive analysis of your building's pitted, pollution stained, faded and

oxidized architectural building facade metal finishes.

A York Property Company technical consultant will

specify a customized long-lasting and cost-effective weathered anodized aluminum building restoration, faded painted

aluminum building restoration and stained silver colored anodized aluminum building

restoration specification that will refurbish, improve, recondition, restore and protect all your architectural metal finishes. |

|

|

|

|

|

| United States:

Alabama, Alaska, Arizona, Arkansas, California, Colorado, Connecticut,

Delaware, Florida, Georgia, Hawaii, Idaho, Illinois, Indiana, Iowa,

Kansas, Kentucky, Louisiana, Maine, Maryland, Massachusetts, Michigan,

Minnesota, Mississippi, Missouri, Montana, Nebraska, Nevada, New

Hampshire, New Jersey, New Mexico, New York, North Carolina, North

Dakota, Ohio, Oklahoma, Oregon, Pennsylvania, Rhode Island, South

Carolina, South Dakota, Tennessee, Texas, Utah, Vermont, Virginia,

Washington, West Virginia, Wisconsin and Wyoming. |

|

| Canada: Alberta, British Columbia, Manitoba, Ontario, Quebec and Saskatchewan. |

|

|

|

|

|