|

|

|

| Client Case

Studies: 1-100 I Before

& After Photo Gallery I Client Testimonials I Contact York Property Co. |

|

|

York

Property Company

provides high quality stained anodized aluminum storefront window frame

cleaning,

oxidized anodized aluminum building facade refinishing, dirty anodized

aluminum building panel restoration and

sun faded anodized aluminum curtain wall refinishing services that

restore the color, gloss, luster, sheen and visual appearance.

Consult with an Expert: Contact the anodized aluminum refinishing experts today at 647.204.5381

and request a comprehensive analysis of your building's stained,

oxidized, faded

and uneven anodized aluminum finishes.

A York Property Company technical consultant will

specify a customized long-lasting and cost-effective

dirty anodized aluminum building facade washing, oxidized

anodized aluminum window mullion refinishing and sun damaged anodized

aluminum curtain wall panel restoration specification that will refurbish,

improve, maintain, restore and protect all your anodized aluminum metal

finishes. |

|

|

Contaminated anodized aluminum panels.

|

|

Refurbished anodized aluminum panels.

|

|

|

|

|

|

| >> View the York Property Company

Before

& After Photo Gallery here. << |

|

|

|

|

|

Case Study 27 -

Faded and Oxidized Anodized Aluminum Panel Restoration

|

|

|

|

|

>> View

Case Study here.

|

|

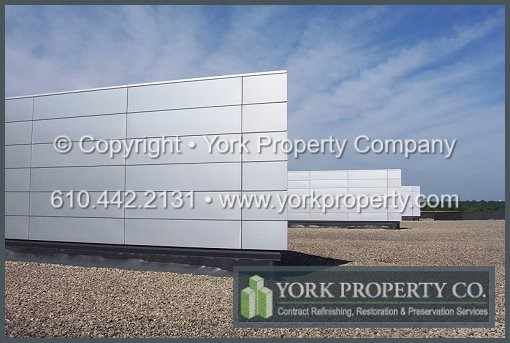

Condition:

From thirty-five years of exposure this low-rise strip industrial

building in Houston, Texas had oxidized clear anodized aluminum metal

panels, stained anodized aluminum doors and sun faded and bleached

anodized aluminum storefront window frames. All of the exterior

anodized aluminum finishes were stained, corroded, pitting and

oxidized. The silver colored anodized aluminum surface finishes were

never washed by rain water and the anodized aluminum finish had

oxidized and degraded prematurely. The anodized aluminum clad building

was for sale and the anodized aluminum building facade needed to look

new, reconditioned and clean again.

York Property

Company Solution:

The owners requested that we clean and restore the oxidized anodized

aluminum building facade panels and bleached anodized aluminum

storefront window frames. As oxidized, weathered, dull and aged

anodized aluminum refinishing experts, with our anodized aluminum

restoration system we were able to refinish, restore and protect the

anodized aluminum window frame and metallic anodized aluminum panel

finishes. When the anodized aluminum refinishing project was complete

the anodized aluminum shined with the original factory gloss and sheen. |

|

|

|

|

|

| Case Study 75 - Restoring the Color on Bronze Anodized Aluminum Panels |

|

|

|

>> View Case Study here. |

|

Condition:

The dark bronze anodized aluminum building facade panels on the

Kimberly-Clark Research & Engineering

building in Neenah, Wisconsin were lacquered after they were installed

on the building. The contractor used the incorrect methods and

materials and over time the lacquer coating on the anodized aluminum

panels started peeling. Cushman & Wakefield, the property

management company, contacted us to strip the lacquer and restore the

anodized aluminum panels to the original luster. The building is

a Class A facility and the unsightly condition of the building facade

had to be remedied. The old weathered lacquer had to be removed. Due to

our renowned anodized aluminum restoration expertise, Cushman &

Wakefield

contracted us to remove the failing lacquer and return the anodized

aluminum panels to their original condition.

York Property Company Solution:

To refurbish and recondition the weathered and faded anodized aluminum panels we had to chemically strip the lacquer

off the anodized aluminum finish without damaging the brown anodic

layer. Removing the lacquer was time consuming and required our skill,

expertise and experience as commercial anodized aluminum panel

restoration contracting specialists. If the panels were

bleached, burned, acid etched or scratched the anodized

aluminum would have to be replaced. The anodized aluminum

reconditioning program got the lacquer off of the anodized aluminum

panels safely and refurbished the anodized aluminum dark brown

color and satin finish. |

|

|

|

|

|

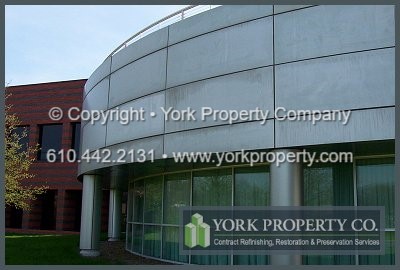

| Case Study 7 - Refurbishing Stained and Oxidized Clear Anodized Aluminum Panels |

|

|

|

>> View Case Study here. |

|

Condition:

The exterior clear anodized aluminum panels on the North Carolina

Museum of Art in Raleigh, North Carolina were faded, stained,

discolored

and oxidized. Our client, the State of North Carolina, had not remedial

maintenance washed the

anodized aluminum clad panels since they were

new. The anodized aluminum panel finishes aged and degraded from

exposure to caustic pollutants, acid rain, the sun, hard water spots

and caustic calcium mineral deposits. The lack of anodized aluminum

washing, care or maintenance caused the anodized aluminum metal finish

to prematurely bleach, corrode, stain, pit and oxidize. Facility

management saw the results of not caring for,

maintaining or washing the anodized aluminum panels and

contacted us for our anodized aluminum restoration and preservation

expertise.

York Property Company Solution:

Our anodized aluminum Technical Consulting Division was contracted to

analyze the degraded exterior anodized aluminum Class

I clear anodic finishes. We found excessive staining, corrosion,

oxidation and anodic finish failure on the majority of the anodized

aluminum panel surfaces. With the findings of our anodized

aluminum surface testing and analysis a long-term anodized aluminum

cleaning, washing and maintenance program was initiated to restore,

protect and preserve the clear anodized aluminum panel system. When

the anodized aluminum panel cleaning, repair, restoration and

protection program was complete the anodized aluminum clad panels

looked clean, fresh and new with the original factory gloss and

sheen. |

|

|

|

|

|

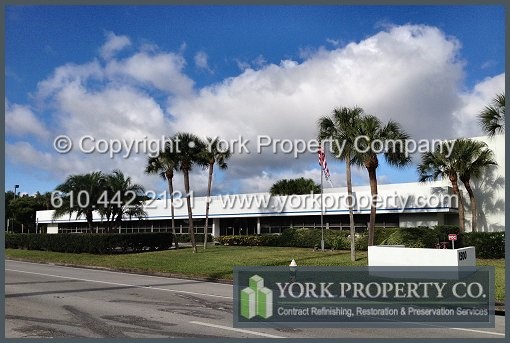

| Case Study 63 - Stripping Faded Paint from Bronze Anodized Aluminum Window Frames |

|

|

|

>> View

Case Study here. |

|

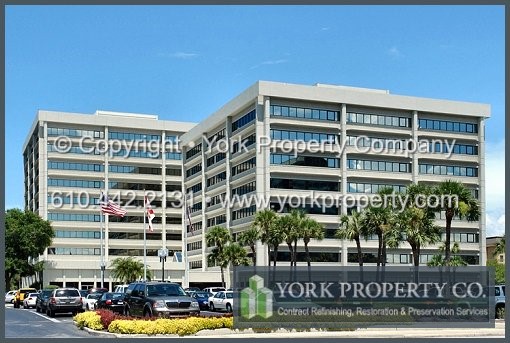

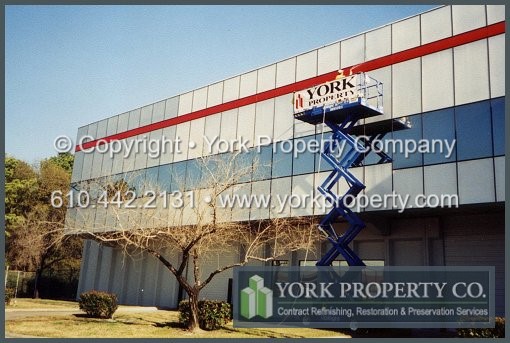

Condition:

The commercial bronze anodized aluminum window frames on this

industrial building in Clearwater, Florida were painted after they were

installed on the building. Over time the brown paint coating on the

anodized aluminum window frames got chalky and the pigment faded. The

old weathered paint had to be removed. The new owner of the building

wanted the anodized aluminum window frames to be restored to the

original luster of new brown colored anodized aluminum. If the anodized

aluminum was not coated once it was clean and refurbished the anodized

aluminum and anodic layer would bleach, stain, acid etch and oxidize.

To maintain the integrity of the brown colored bronze anodic finish

ownership requested the anodized aluminum storefront window frames be

coated and protected with the York Property Company anodized aluminum

clear protective coating.

York Property

Company

Solution:

To refurbish and recondition the weathered and faded anodized aluminum

window frames we had to chemically strip the paint off the anodized

aluminum finish without damaging the brown anodic layer. Removing the

paint was time consuming and required our skill, expertise and

experience as commercial anodized aluminum window frame restoration

contracting specialists. If the window frames were bleached, burned,

acid etched or scratched the anodized aluminum would have to be painted

again. The anodized aluminum reconditioning program got the paint off

of the anodized aluminum window frames safely and refurbished the

anodized aluminum dark brown color and finish. The anodized aluminum

protective coating enhanced the reflective sheen and gloss while

protecting the anodized aluminum from the sun, mineral deposits,

calcium stains and caustic airborne contaminants. |

|

|

|

|

|

| Case Study 80 - Stained and Oxidized

Anodized Aluminum Window Frame Refinishing

|

|

|

|

>> View

Case Study here. |

|

Condition: The old exterior clear

anodized aluminum window frames on this commercial building in Austin,

Texas displayed severe discoloration, oxidation, staining and corrosion

from fifty-five years of weathering and a lack of preventive

maintenance washing. There were marks, dings, scuffs and scrapes from

the years of the window cleaning contractor repelling the side of the

building. The factory anodized aluminum window frame finish lost the

original sheen, gloss, color depth and luster. The new owners of the

building wanted to improve the appearance, renew, brighten, refurbish

and protect the commercial grade anodized aluminum window frames.

Anodized aluminum window frame refinishing will protect and preserve

the exterior anodized aluminum finishes from weathering, pollutants,

contaminants, hard water stains, mold, mildew and the corrosive

damaging elements.

York Property Company Solution:

To clean, repair, renew and protect the anodized aluminum window frame

surface finishes from further oxidation, corrosion, pitting and

deterioration we cleaned and refurbished the original silver gray

colored anodized finish with our oxidized anodized aluminum cleaning

and renovation system. Without painting, our oxidized anodized aluminum

window frame refinishing and refurbishing program returned the anodized

aluminum window frame factory finish to as good as new and now protects

the anodized finish from weathering, pitting, oxidation and corrosion.

The anodized aluminum window frame finishes have the original satin

sheen, rich color depth and gloss and are protected from further

damage, oxidation and corrosion. |

|

|

|

|

|

| Case Study 24 - Faded and Oxidized Anodized Aluminum Metal Siding Refinishing

|

|

|

|

>> View

Case Study here. |

|

Condition:

The exterior mold stained clear anodized aluminum metal siding panels,

mildew discolored anodized aluminum window frames and dirty anodized

aluminum window mullions on this commercial building in Boise, Idaho

were stained, faded, dull and oxidized. The anodized aluminum metal

clad siding panels were mold and mildew stained in the areas where the

siding was shaded by the trees. The owner was selling the anodized

aluminum clad commercial office building and required that the

oxidation, mold and mildew stains be removed and that the natural

silver colored anodized aluminum siding panels be clean.

York Property

Company Solution:

The damaged and stained anodized aluminum metal siding, anodized

aluminum window frames and anodized aluminum mullions on this building

facade were cleaned, repaired and refurbished with our anodized

aluminum mold and mildew stain removal program. Using this program

removed the stains from the anodized aluminum and allowed us to apply

our anodized aluminum clear protective coating to protect the natural

silver anodized aluminum siding color from caustic and damaging mold,

mildew, pollutants and contaminants. |

|

|

|

|

|

| Case Study 74 - Exterior Oxidized Anodized Aluminum Window Frame Refinishing |

|

|

|

>> View

Case Study here. |

|

Condition: The anodized aluminum

building facade window frames on this commercial building in Sarasota,

Florida were faded, pitted, oxidized, bleached and stained. The

anodized aluminum window frames looked old, dirty, aged and faded as

they had never been cleaned, washed or maintained since the building

was new. To protect the anodized aluminum from further damage Property

Management wanted the anodized aluminum cleaned, repaired and restored.

York Property Company Solution:

The exterior anodized aluminum building facade window frames were

refurbished with our exterior anodized aluminum cleaning and

refinishing system. The anodized aluminum was restoration cleaned and

the anodized aluminum window frames were coated with the specified

clear protective coating. With the anodized aluminum surfaces now

clean, the coating will preserve and protect the anodic layer from

airborne and waterborne contaminants, sun and u.v exposure and all

around general weathering. |

|

|

|

|

|

| Case Study 37 - Stripping Peeling Lacquer off of Bronze Anodized Aluminum Panels |

|

|

|

>> View

Case Study here. |

|

Condition:

The dark bronze anodized aluminum building facade panels on this

commercial

building in Neenah, Wisconsin were lacquered after they were installed

on

the building. Over time the lacquer coating on the anodized aluminum

panels got chalky, flaky and started peeling. Cushman & Wakefield wanted the anodized aluminum panels to be restored to the

original luster of new brown colored anodized aluminum. The building is

a Class A facility and the unsightly condition of the building facade

had to be remedied. The old weathered lacquer had to be removed. Due to

our renowned anodized aluminum restoration expertise, our client

contracted us to remove the failing lacquer and return the anodized

aluminum panels to their original condition.

York Property Company Solution:

To refurbish and recondition the weathered and faded anodized aluminum panels we had to chemically strip the lacquer

off the anodized aluminum finish without damaging the brown anodic

layer. Removing the lacquer was time consuming and required our skill,

expertise and experience as commercial anodized aluminum panel

restoration contracting specialists. If the panels were

bleached, burned, acid etched or scratched the anodized

aluminum would have to be replaced. The anodized aluminum

reconditioning program got the lacquer off of the anodized aluminum

panels safely and refurbished the anodized aluminum dark brown

color and satin finish. |

|

|

|

|

|

| Case Study 88 - Aluminum Building Facade Corrugated Siding Panel Restoration |

|

|

|

>> View

Case Study here. |

|

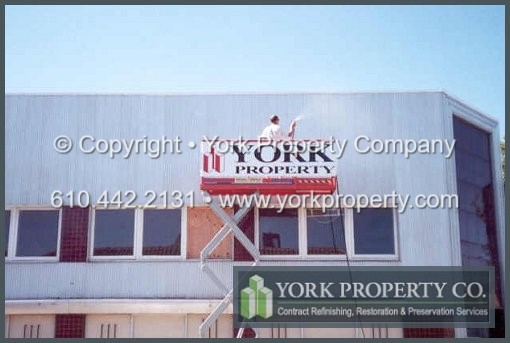

Condition:

The corrugated aluminum clad siding on this historical retail building

in San Mateo, California was stained, weathered and severely oxidized

from decades of exposure to the California sun. The aluminum siding

panels were acid etched, bleached and the finish was uneven. The

aluminum silver color was faded and satin sheen was dull. The building

owner required our expertise to clean repair, renew and restore the

aluminum building siding panels.

York Property

Company Solution:

Working with the owner and an architect our Technical Consulting

Division specified an aluminum siding cleaning, refinishing,

maintenance and preservation solution. Ownership wanted the aluminum

siding refurbished and the factory finish gloss and luster returned to

the aluminum panels. We cleaned, repaired, resurfaced and restored the

oxidized aluminum siding and spray applied a lacquer coating to protect

the aluminum siding from corrosion, salt air, UV damage, pollutants,

weathering and contaminants. |

|

|

|

|

|

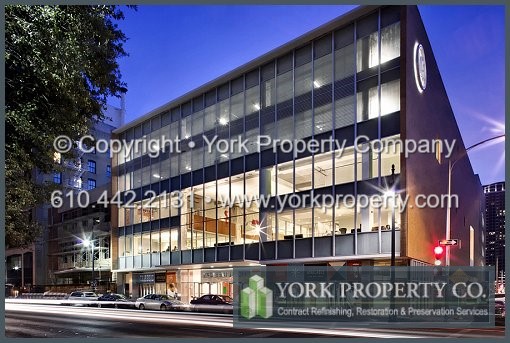

| Case Study 72 - Anodized Aluminum Column

Cover Cleaning and Corrosion Protection |

|

|

|

>> View

Case Study here. |

|

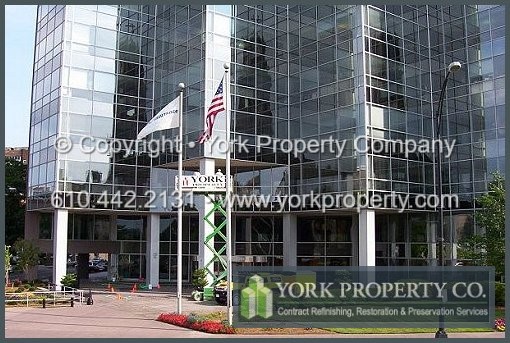

Condition:

This clear anodized aluminum clad building is located in downtown

Toronto, Ontario. Automobile exhaust, street grime, winter salt, pollution, dirt

and chemicals had attacked the anodized aluminum finishes. The silver

gray anodized aluminum column cover cladding was dirty, stained,

oxidized and contaminated. The anodized aluminum was never cleaned or

maintenance washed properly to remove all of the corrosive particulate

that had accumulated on the anodized aluminum surfaces. To improve the

appearance of the anodized aluminum, management wanted the anodized

aluminum cleaned and washed. As well, the anodized aluminum finishes

had to be protected from winter salt damage, pollution, dirt and street

level grime.

York Property Company Solution:

The anodized aluminum commercial building column cover cladding

required our dirty anodized aluminum metal cleaning and stained

anodized aluminum refinishing expertise to clean, refurbish and restore

the anodized aluminum column covers to the original satin sheen, silver

metallic color, gloss and luster while maintaining the integrity of the

anodized aluminum metal finish for years to come. This involved

repairing the damaged, resurfacing the oxidized and restoring the faded

anodized aluminum factory finish. Once the anodized aluminum

restoration was complete we spray applied our anodized aluminum lacquer

coating to protect the anodized aluminum cladding panels from

corrosion, salt water residue, UV damage, pollutants, weathering and

contaminants. |

|

|

|

|

|

| Case Study 54 - Stained and Oxidized Anodized Aluminum Building Facade Refinishing

|

|

|

|

>> View

Case Study here. |

|

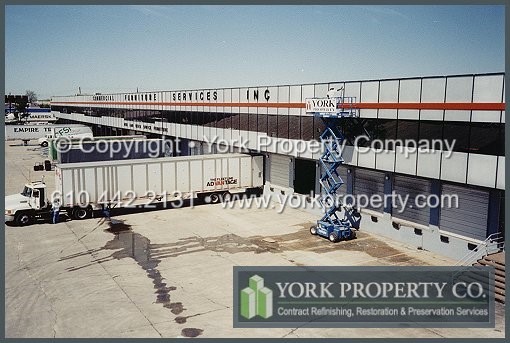

Condition:

This thirty-seven year old industrial building in Houston, Texas had

dirty smog stained clear anodized aluminum building facade metal

panels, stained anodized aluminum doors and faded black anodized

aluminum window frames due to continuous exposure to the South Texas

environment of heat, humidity, sun and UV exposure which caused the

panels to age, deteriorate and bleach considerably. The exterior

stained, sun faded, dull and oxidized natural colored anodized aluminum

panels, window frames and doors looked dirty, prematurely old and no

longer clean. Facility management requested that the anodized aluminum

be cleaned, refurbished and protected from further damage.

York Property Company Solution:

This specific anodized aluminum restoration project had many challenges

as the industrial building was a depot for a large furniture

manufacturing company and at all times during the day all fifty-two

loading bays were in use. The exterior anodized aluminum building

components were cleaned, repaired and restored with our sun damaged

exterior anodized aluminum cleaning and oxidized anodized aluminum

refinishing system. The silver metallic Alucobond anodized aluminum was

restoration cleaned and the metal panels were coated with the specified

clear protective coating. With the anodized aluminum surfaces now

clean, the coating will preserve and protect the anodic layer from

airborne and waterborne contaminants, sun and UV exposure and all

around general corrosive weathering. |

|

|

|

|

|

| Case Study 1 - Faded and Oxidized Anodized Aluminum Building Panel Restoration |

|

|

|

>> View

Case Study here.

|

|

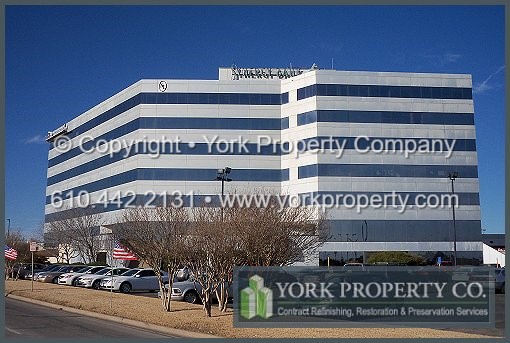

Condition:

The exterior oxidized clear anodized aluminum building facade panels

and stained anodized aluminum window frames on this owner occupied ADP,

Inc. commercial office building in Tampa, Florida were faded,

weathered, bleach, sun and UV damaged. As well, the discolored ground

floor anodized aluminum panels were stained with calcium, hard water

stains and mineral deposits from the sprinkler system. The exterior

natural colored anodized aluminum was not clean and the owners required

the anodized aluminum siding panels and extrusions be refinished and

restored. The oxidized anodized aluminum refinishing project would

renew the anodized aluminum finishes to the original factory anodized

aluminum gloss, color and sheen.

York Property

Company

Solution: Our anodized aluminum Technical Consulting Division

was contracted to analyze the faded, sun damaged and stained silver

grey anodized aluminum clad siding panels and bleached anodized

aluminum window mullions. With an analysis of the damaged anodized

aluminum finishes a long-term anodized aluminum cleaning, washing and

maintenance program was implemented to clean, refurbish, preserve and

protect the oxidized anodized aluminum clad siding and mineral stained

anodized aluminum window frames. When the anodized aluminum was

restored by our field technicians the anodized aluminum building

extrusions looked as new as the original date of installation. |

|

|

|

|

|

| Case Study 9 - Alucobond Anodized

Aluminum - Failed Coating Removal and Refinishing |

|

|

|

>> View

Case Study here.

|

|

Condition: The clear anodized

aluminum Alucobond panels on this commercial building in Waco, Texas

were painted after they were installed on the building. The silver grey

paint coating on the anodized aluminum was peeling and the old,

brittle, flaking paint had to be removed. Specialty Property wanted the

anodized aluminum clad panels to be restored to the original luster of

new anodized aluminum. If the anodized aluminum was not coated once it

was clean and refurbished the anodized aluminum would bleach, stain,

acid etch and oxidize. To maintain the integrity of the Alucobond

anodic finish ownership requested the anodized aluminum building facade

siding panels be coated and protected with the York Property Company

anodized aluminum protective coating.

York Property Company Solution:

To refurbish and recondition the old, faded and contaminated anodized

aluminum we had to strip the paint off the anodized aluminum finish

without damaging the anodic layer. Removing the paint was time

consuming and required our skill, expertise and experience as anodized

aluminum restoration specialists. If the Alucobond panels were acid

etched or scratched the anodized aluminum would have to be painted

again. The anodized aluminum reconditioning program got the paint off

of the panels safely and refurbished the anodized aluminum color and

finish. The anodized aluminum protective coating enhanced the natural

color and sheen while protecting the anodized aluminum from the sun,

dark grey mineral deposits, milky white calcium stains and caustic

airborne contaminants. |

|

|

|

|

|

| Case Study 26 - Corroded

Anodized Aluminum Column Cover Refinishing |

|

|

>> View

Case Study here.

|

|

Condition:

The exterior clear anodized aluminum doors and frames, anodized

aluminum metal clad column covers and anodized aluminum storefront

window mullions on this commercial building in Winston-Salem, North

Carolina were pitted, streaked, stained, corroded and oxidized. The

anodized aluminum finishes had no remedial maintenance washing since

they were new. The owners, G.M.A.C., requested that we clean, repair

and restore the degraded and bleached anodized aluminum to preserve the

anodized finishes.

York Property Company

Solution: To clean, refurbish and restore the

contaminated, corroded and degraded exterior anodized aluminum we

installed our oxidized anodized aluminum cleaning and deteriorated

anodized aluminum restoration refinishing system. With the silver

colored anodized aluminum surfaces now clean, the anodized aluminum

clear protective coating will preserve and protect the anodized

aluminum anodic layer from airborne and waterborne contaminants, sun

and UV exposure and all around general weathering. |

|

|

|

|

|

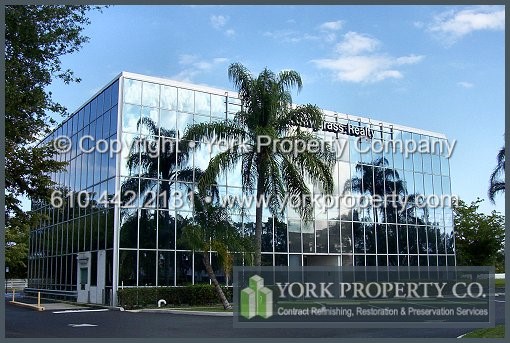

Case Study 2 -

Restoring Oxidized Bronze Anodized Aluminum Window Frames

|

|

|

>> View

Case Study here.

|

|

Condition:

A lack of washing the exterior dark bronze anodized aluminum cladding,

siding panels and window frames on this twenty-three year old owner

occupied commercial building in Park Ridge, New Jersey caused the anodized

aluminum to bleach, stain, acid etch and oxidize. Without washing the

anodized aluminum it aged from exposure to airborne and waterborne

contaminants, pollutants, acid rain, sun damage and UV exposure. The

lack of maintenance washing contributed to the corrosion and pitting on

the anodized metal finishes. Ownership had not followed the anodized

aluminum manufacturers washing and preventive maintenance schedule

since the anodized aluminum was new.

York Property Company Solution:

Sartak Holdings realized that anodized aluminum washing and

maintenance was vital to maintain the twenty-three year old anodized

finish over the long-term. We were contacted to analyze the degraded,

stained, corroded, pitting and oxidized exterior bronze anodized

aluminum mullions, window frames, siding and cladding panels. With the

findings of our analysis and specification we were contracted to clean,

wash, refinish and maintain the contaminated anodized aluminum

finishes. Our anodized aluminum cleaning and refinishing system

cleaned, refurbished and protected the anodized aluminum restoring the

original color, gloss and sheen to the bronze anodized finish. |

|

|

|

|

|

| Case Study 4 -

Restoring Dirty and Silicone Caulking Stained Anodized Aluminum Panels |

|

|

>> View

Case Study here. |

|

Condition:

The clear anodized aluminum panels on the exterior of the VA Hospital

in Bronx, New York had degraded from forty years of exposure to

airborne and waterborne contaminants. The anodized aluminum clad panels

were dirty, stained and discolored showing its age. The petroleum-based

window gaskets and silicone caulking had degraded leaching an oily

residue on the surface of the clear anodized aluminum. Until management

worked with us, they could not find anyone to clean, refinish and

restore the damaged anodized aluminum building facade panels. Our

client, the United States Department of Veterans Affairs, wanted the

silver colored anodized aluminum clad building clean, restored and the

black stains and silicone caulking residue removed.

York Property Company Solution:

We worked with Fellenzer Engineering LLP of Middletown, New York on the

anodized aluminum surface damage analysis and the correct anodized

aluminum cleaning and refinishing specification for the cleaning,

restoration and protection of the clear anodized aluminum panels. The

dirty, weathered and stained anodized aluminum cleaning posed many

challenges. As the building is a hospital, we had to be sensitive to

the doctors, patients and pedestrians within and around the facility.

Our decades of anodized aluminum refinishing expertise allowed our

on-site field technicians to clean and restore the silver colored

anodized aluminum surface finishes. Our anodized aluminum spray applied

protective lacquer coating sealed the pores of the anodic finish. The

forty-year-old anodized aluminum finish now has the original sheen,

natural color and luster. |

|

|

|

|

|

| Case Study 29 - Pitted Anodized Aluminum Window Frame Break Metal Capping |

|

|

>> View

Case Study here.

|

|

Condition:

The clear anodized

aluminum window frames on this Ocean Front Resort in Myrtle Beach,

South Carolina displayed severe discoloration, oxidation, staining,

pitting and corrosion from thirty years of weathering and salt water /

salt air damage. The clear anodized aluminum window frame finishes had

lost the original sheen, gloss, color depth and luster. The resort

owner wanted to renew, brighten and refurbish the anodized aluminum

window frames; without painting or changing the color to black or

bronze anodized. Class I anodized aluminum window frame capping would

achieve the objective while protecting the exterior anodized aluminum

finishes from weathering, salt, contaminants, hard water stains, mold,

mildew and the corrosive damaging elements.

York Property Company

Solution: To meet our client's capping objective required

shipping 7000 linear feet of new Class I anodized aluminum break metal

sheet stock to the Resort. Our on-site technicians spent 5 months

breaking the anodized aluminum into the correct capping shapes. The

breaking of the anodized aluminum capping required precise measuring

and field cutting to insure a perfect capping installation. Without

painting, our pitted and oxidized anodized aluminum window frame

capping system returned the anodized aluminum window frame factory

finish to new and now protects the anodized finish from weathering,

pitting, oxidation and corrosion. The anodized aluminum clad window

frame finishes have the original satin sheen, silver gray color depth

and metallic gloss and are protected from further sun and salt

damage, oxidation and corrosion. |

|

|

|

|

|

Case Study 21 -

Dirty Anodized Aluminum Curtain Wall Panel Restoration

|

|

|

>> View

Case Study here.

|

|

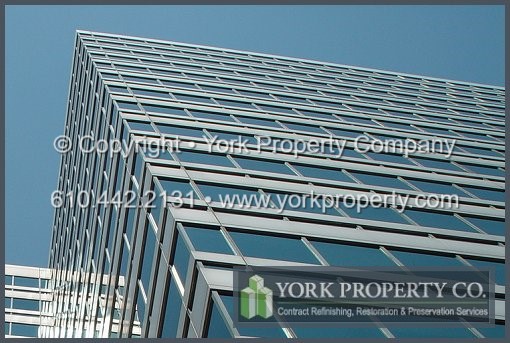

Condition:

The dirty anodized aluminum curtain wall panels, faded anodized

aluminum column covers and stained anodized aluminum window mullions

on this commercial high-rise building in downtown Toronto, Ontario had

degraded from years of exposure. The anodized aluminum metal

curtain wall, anodized aluminum ground floor storefront doors and

anodized aluminum window frames were chemically damaged, etched,

oxidized and discolored. The petroleum based window gaskets had

degraded leaching an oily residue on the surface of the clear anodized

aluminum. The new building owner wanted the anodized aluminum clad

commercial building clean, restored and the black stains and oil

residue removed.

York Property Company Solution:

Before we refurbished and restored the twenty-one storey anodized

aluminum commercial curtain wall system the old and degraded window

gaskets were replaced. Our oxidized anodized aluminum metal refinishing

expertise allowed our technicians to clean, repair and restore the

silver colored anodized aluminum surface finishes. Our anodized

aluminum spray applied protective lacquer coating sealed the pores of

the anodic finish. The anodized aluminum finish now has the original

sheen, natural color and luster and will for years to come. |

|

|

|

|

|

| Case Study 92 -

Removing Peeling Paint from Bronze Anodized Aluminum Window Frames |

|

|

>> View

Case Study here. |

|

Condition: The Kawneer Class I

exterior bronze anodized aluminum window frames on these commercial

buildings in Tampa, Florida were painted after they were installed on

the building. The brown paint coating on the anodized aluminum window

frames were peeling and the old, brittle, flaking paint had to be

removed. The owners wanted the anodized aluminum window frames to be

restored to the original luster of new brown colored anodized aluminum

window frames, sills and flashing. If the anodized aluminum was not

coated once it was clean and refurbished the anodized aluminum and

anodic layer would bleach, stain, acid etch and oxidize. To maintain

the integrity of the brown colored bronze anodic finish ownership

requested the anodized aluminum building facade window frames be coated

and protected with the York Property Company anodized aluminum clear

protective coating.

York Property Company Solution:

To refurbish and recondition the old, faded and contaminated exterior

anodized aluminum window frames we had to chemically strip the paint

off the anodized aluminum finish without damaging the brown anodic

layer. Removing the paint was time consuming and required our skill,

expertise and experience as commercial anodized aluminum window frame

restoration contracting specialists. If the window frames were

bleached, burned, oxidized, acid etched or scratched the anodized

aluminum would have to be painted again. The anodized aluminum

reconditioning program got the paint off of the anodized aluminum

window frames safely and refurbished the anodized aluminum dark brown

color and finish. The anodized aluminum protective coating enhanced the

reflective sheen and gloss while protecting the anodized aluminum from

the sun, mineral deposits, calcium stains and caustic airborne

contaminants. |

|

|

|

|

|

| Case Study 12 - Weathered Anodized Aluminum Building Facade Panel Restoration |

|

|

>> View

Case Study here.

|

|

Condition:

The clear anodized aluminum clad building facade panels and anodized

aluminum window frames on this owner occupied commercial building in

Houston, Texas were oxidized, bleached, pitted and stained. The

anodized aluminum panels looked old, aged, dull, weathered and faded as

they had never been cleaned, washed or maintained since the anodized

aluminum clad building was new. ADP, Inc. wanted to clean, refurbish

and protect the damaged exterior natural colored Duranodic anodized

aluminum clad composite panel system.

York Property Company Solution:

The anodized aluminum cladding was cleaned, repaired and restored with

our exterior oxidized anodized aluminum cleaning and stained anodized

aluminum refinishing system. The anodized aluminum was restoration

cleaned and the metal clad panels were coated with our anodized

aluminum clear protective coating. With the anodized aluminum surfaces

now clean, the coating will preserve and protect the anodized aluminum

anodic layer from airborne and waterborne contaminants, sun and UV

exposure and all around general weathering. |

|

|

|

|

|

Case Study 49 -

Cleaning and Refurbishing Stained Anodized Aluminum Cladding

|

|

|

>> View

Case Study here.

|

|

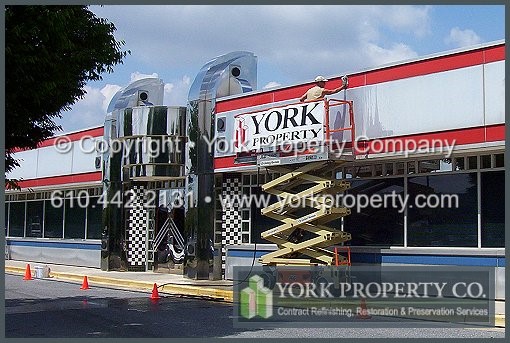

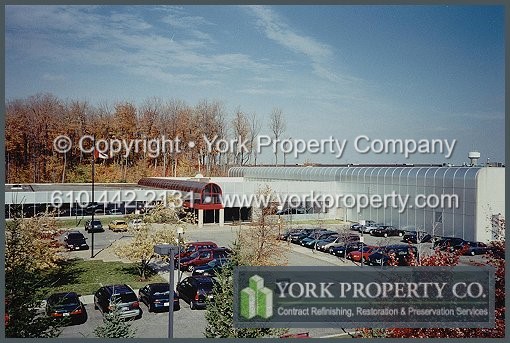

Condition:

The exterior clear anodized aluminum siding panels on this

entertainment facility in Gaithersburg, Maryland were faded, stained,

dull and oxidized. Our client had not washed the silver gray colored

anodized aluminum clad siding panels since they were new. The anodized

aluminum siding aged from exposure to pollutants, acid rain, the sun,

hard water spots and caustic mineral deposits. The lack of anodized

aluminum washing, care or maintenance caused the anodized aluminum

metal finish to prematurely bleach, corrode, stain, pit and oxidize.

Management saw the results of not caring for, maintaining or washing

the anodized aluminum cladding and contacted us for our anodized

aluminum restoration and preservation expertise.

York Property Company Solution:

Our anodized aluminum Technical Consulting Division was contracted to

analyze the degraded exterior anodized aluminum panels and metal

finishes. We found excessive staining, corrosion, oxidation and anodic

finish failure on the majority of the anodized aluminum surfaces. With

the findings of our anodized aluminum surface testing and analysis we

informed our client that the anodized aluminum finishes could be

cleaned and restored and did not require painting. A long-term anodized

aluminum cleaning, anodized aluminum washing and anodized aluminum

maintenance program was initiated to restore, protect and preserve the

anodized aluminum clad siding. When the anodized aluminum cleaning,

repair, restoration and protection program was complete the anodized

aluminum clad siding panels looked clean, fresh and new. |

|

|

|

|

|

| Case Study 39 - Refinishing Salt Water Oxidized Anodized Aluminum Window Frames |

|

|

>> View

Case Study here.

|

|

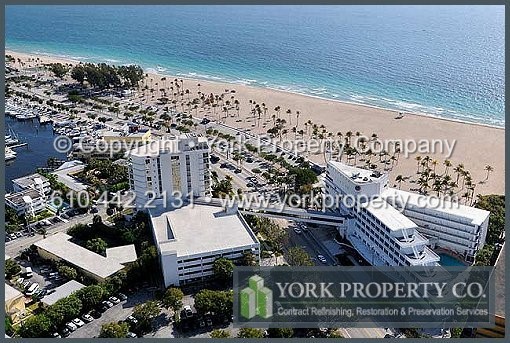

Condition: The oxidized anodized

aluminum window frames, bleached anodized aluminum sliding doors and

sun faded anodized aluminum balcony railings on this Fort Lauderdale, Florida

oceanfront hotel are continually exposed to the sun, UV rays,

humidity, heat, salt water mist and corrosive salt air. In this

damaging and caustic environment the clear natural colored anodized

aluminum metal finishes had weathered, oxidized, pitted and stained.

The original gloss and silver color of the anodized aluminum anodic

finish had faded, bleached and was damaged by salt in the environment.

The new hotel owners saw the results of not washing, caring for or

maintaining the anodized aluminum window mullions and frames, anodized

aluminum sliding glass doors and anodized aluminum railings.

York Property Company Solution:

The new owners required the anodized aluminum continually look new and

clean and not have any oxidation, stains or salt residue contamination.

As anodized aluminum oxidation removal, anodized aluminum pitting and

corrosion removal and anodized aluminum refinishing specialists we

specified the correct cleaning methods and renovation materials. This

anodized aluminum restoration specification enabled the stucco painting

contractor to refurbish the anodized aluminum surface finishes while

the access equipment was on-site. The spray applied lacquer now

protects the anodized aluminum window mullions from salt water damage,

salt air damage, corrosive pollutants, airborne contaminants and salt

water mist associated with an oceanfront hotel. |

|

|

|

|

|

Case Study 32 - Restoring Silicone Caulking Stained Anodized Aluminum Panels

|

|

|

>> View

Case Study here.

|

|

Condition:

The stained clear anodized aluminum metal building facade panels, old

anodized aluminum window frames and deteriorated anodized aluminum clad

column panels were silicone contaminated from leeching and degraded

caulking. The original clear anodized aluminum Duranodic panels on this

commercial building in Madison, Wisconsin were discolored, uneven,

faded and did not match the newly built clean anodized aluminum

stair-tower panels. The aged, faded and weathered original panels with

the silicone caulking staining damage were in need of anodized aluminum

cleaning, repair and restoration.

York Property Company Solution:To

achieve the desired result this project required our silicone

caulking stained anodized aluminum construction cleaning and our faded

and weathered aluminum restoration refinishing system. With these

commercial grade anodized aluminum restoration systems we were able to

clean and repair the staining damage without damaging the silver gray

colored anodized aluminum panels during the restoration process. We

exceeded ownership's expectations as the new clean stair-tower panels

match the original clean and refinished silver metallic panels. |

|

|

|

|

|

| Case Study 28 - Bleached Clear

Anodized Aluminum Building Facade Restoration |

|

|

>> View

Case Study here.

|

|

Condition:

The exterior clear anodized aluminum building facade clad panels and

anodized aluminum window mullions on this commercial building in Tampa,

Florida are continually exposed to the damaging sun, heat, corrosive

humidity and UV rays. The anodized aluminum was bleached, stained,

acid etched and oxidized. To maintain the integrity of the Alucobond

anodic finish ownership requested the anodized aluminum building facade

siding panels be clean, restored and protected.

York Property Company

Solution: Our anodized aluminum Technical Consulting

Division was contracted to analyze the degraded, corroded, sun damaged

and weathered anodized aluminum building facade window mullions and

oxidized anodized aluminum clad panels. As gray colored anodized

aluminum oxidation removal, anodized aluminum pitting repair and

anodized aluminum refinishing experts we specified an on-site anodized

aluminum cleaning, refinishing and preventive maintenance program. |

|

|

|

|

|

| Case Study 69 - Restoring Oxidized, Stained and Faded Anodized Aluminum Panels |

|

|

>> View

Case Study here.

|

|

Condition:

The clear anodized aluminum building facade panels, anodized aluminum

mullions, anodized aluminum storefront window frames and anodized metal

extrusions on this commercial building in Markham, Ontario were dirty, oxidized and

stained. The anodized silver color and satin sheen had faded. The

anodized aluminum cladding panels were contaminated with mold, mildew,

mineral and calcium deposits. Apple Computer Inc. wanted a mold and

mildew stain removal program to repair, restore and refinish the

anodized metal surface staining and damage to the anodized aluminum

building facade panels.

York Property

Company

Solution: The dull, bleached and damaged exterior anodized

aluminum panels and anodized aluminum window frames on this building

were cleaned, repaired and restored with our exterior anodized aluminum

refinishing system. The anodized aluminum was restoration cleaned

removing the oxidation, mold and mildew stains, and the calcium and

mineral deposits. The anodized aluminum metal cladding and anodized

aluminum metal storefront window frames were coated with our spray

applied clear lacquer protective coating to protect the anodized

aluminum metal finish from further damage, corrosion and weathering. |

|

|

|

|

|

| Case Study 8 - Oxidized Bronze Anodized Aluminum Panel Restoration |

|

|

>> View

Case Study here. |

|

Condition:

A lack of remedial maintenance washing of the exterior dark bronze

anodized aluminum clad panels at Kimberly-Clark's office campus in Neenah, Wisconsin caused the

brown anodized aluminum panels to bleach, stain, acid

etch and oxidize. As the anodized aluminum panels were never

washed or polished they aged from exposure to airborne and waterborne

contaminants, pollutants, acid rain, sun damage and UV exposure. The

lack of maintenance washing contributed to the corrosion and pitting on

the bronze anodized aluminum metal finishes. Ownership had not followed

the original anodized aluminum manufacturers washing and preventive

maintenance schedule since the anodized aluminum panels were new.

York Property Company Solution:

Jones Lang LaSalle, building management, realized that anodized aluminum panel

washing and maintenance was vital to maintain the thirty-three year old

bronze anodized aluminum anodic finish over the long-term. We were

contacted to analyze the degraded, stained, corroded, pitting and

oxidized exterior bronze anodized aluminum cladding panels. With the findings of our analysis and

specification we were contracted to clean, wash, refinish and maintain

the contaminated bronze anodized aluminum finishes. Our anodized

aluminum cleaning and refinishing system cleaned, refurbished and

protected the anodized aluminum panels, restoring the

original natural brown color, gloss and sheen to the bronze anodized

finish. |

|

|

|

|

|

| Case Study 68 - Discolored and Oxidized

Anodized Aluminum Panel Refinishing |

|

|

>> View

Case Study here.

|

|

Condition:

The clear anodized aluminum clad siding panels on this commercial building in Madison, Wisconsin displayed severe

discoloration, oxidation, staining and corrosion from years of

weathering and a lack of preventive washing or maintenance. The factory

anodized finish lost the original sheen, gloss, color depth and luster.

Management decided to refurbish, renew and rejuvenate the original

factory anodized aluminum finish to avoid chipping, peeling and flaking

paint. Refurbishing the anodized finish will protect and preserve the

exterior anodized aluminum siding panels from weathering, pollutants,

contaminants, hard water stains, mold, mildew and the damaging elements.

York Property

Company Solution:

To clean, repair, renew and protect the anodized aluminum siding from

further oxidation, corrosion, pitting and deterioration we cleaned and

refurbished the original anodized finish with our anodized aluminum

cleaning and renovation system. Without painting, our oxidized anodized

aluminum refinishing and refurbishing program returned the anodized

aluminum factory finish to as good as new and now protects the anodized

finish from weathering, pitting, oxidation and corrosion. The anodized

finish has the original sheen, color depth and gloss protected from

further damage. |

|

|

|

|

|

| Case Study 19 - Repairing Oxidized Anodized Aluminum Building Facade Panels |

|

|

|

>> View

Case Study here.

|

|

Condition:

The exterior clear anodized aluminum clad building facade panels,

anodized aluminum window frames and anodized aluminum entrance doors on

this building in Toronto, Ontario were faded, stained, dull and oxidized.

The anodized aluminum building looked dirty, discolored, streaked and

was showing its age. For long-term integrity considerations the owners

requested that we clean, repair and restore the damaged, bleached and

scratched natural silver colored anodized aluminum clad paneling and

anodized aluminum window frames.

York Property Company Solution:

The dirty anodized aluminum building facade cleaning and oxidized

anodized aluminum restoration posed many challenges. We could not clean

the anodized aluminum or work on the exterior of the building during

regular business hours as we would obstruct the main entrance. The

anodized aluminum building facade panels were restored over a long

weekend to "like new". Our anodized aluminum oxidation cleaning,

anodized aluminum scratch removal, weathered anodized aluminum

restoration and anodized aluminum clear protective coating programs

left the anodized aluminum cladding clean, restored and protected. |

|

|

|

|

|

| Case Study 52 - Weathered and Aged

Anodized Aluminum Building Facade Restoration |

|

|

|

>> View

Case Study here.

|

|

Condition:

The exterior clear anodized aluminum spandrel panels on this owner occupied commercial /

industrial building in Houston, Texas were severely bleached, sun faded

and oxidized from exposure to diesel exhaust, industrial pollution,

corrosive acid rain, ultraviolet exposure and a lack of anodized

aluminum remedial maintenance washing. Until management worked with us,

they could not find anyone to clean, refinish or restore the damaged,

stained and weathered anodized aluminum building facade metal panels.

The anodized aluminum clad building was for sale and the anodized

aluminum siding panels needed to be refurbished. The anodized color was

bleached and the anodized metal sheen was dull. Building management

refused to paint the building and were set on restoring the original

satin finish of the clear anodized aluminum.

York Property Company Solution:

A York Property Company Technical Advisor assisted management with the

anodized aluminum surface damage analysis and the correct oxidized

anodized aluminum cleaning and sun faded anodized aluminum refinishing

specification for the cleaning, repair, renovation and restoration of

the anodized aluminum building facade metal panels. We refurbished,

reconditioned and restored the anodized aluminum cladding as if it had

not been stained, blemished or damaged. The anodized aluminum surface

corrosion, oxidation and airborne particulate is gone and the gray

silver colored anodized aluminum finish is renewed and clean. The

anodized aluminum is now protected from automobile exhaust, weathering,

sun and UV exposure, acid rain and pollution. |

|

|

"We

could not find anyone that could restore

our anodized aluminum facade. The only recommendation that we had

was to paint

the anodized aluminum facade. The president of our company refused to

have the

anodized aluminum buildings painted because of continuous maintenance -

in fact we were

going to replace the entire anodized aluminum facade unless we could

find someone to do

the proper job of anodized aluminum restoration. We cannot thank you

enough not

only for your performance but also your ability to return our anodized

aluminum to its original beauty and luster."

Vice President,

Amega Corporation |

|

|

| >> More York Property Company Client

Testimonials here.

<< |

|

|

|

|

|